Home » Articles posted by Tessa Sanderson (Page 15)

Author Archives: Tessa Sanderson

Contractors Get First Glimpse of Deere Electric 310 X-Tier Backhoe (Video)

Product details are still sketchy after all, it’s still a test machine but John Deere used the Utility Expo to strut out its electric backhoe, the 310 X-tier E-Power, now in real-world testing with utility client National Grid.

“The battery electric technology on the 310 X-tier is one way we’re going to give leading-edge performance with innovative technology,” says Justin Steger, Deere solutions marketing manager. “It is geared toward customers that have stated carbon emissions-reduction goals.”

Throughout the spring and summer, National Grid used the machine to perform a variety of jobs, including trenching, loading, digging, backfilling and using a breaker, says Brian Hennings, Deere product manager, speaking to Equipment World. Up next: cold-weather tests.

The “X-tier” identifies that it has a unique power train, says Hennings. “If we eventually do come out in the marketplace and things look very positive — the model would be offered as a 310 X.”

The placard next to the 310 X-tier at the Utility Expo said the machine represented an “early Phase 1 development in clean-energy solutions,” the same language Deere used in its January announcement that it was testing the machine. Deere will head into Phase 2 testing next year, Hennings says, and targeting energy consumption by specific components. “We want to offer at least an 8- to 10-hour composite runtime,” he says.

“We’re very early in this journey, and it’s going to take many iterations to meet customer expectations,” Hennings says, noting that even retaining the top 25 mph travel speed can consume a great deal of power. “It’s going to be more a matter of years instead of a matter of months.”

The 310 X-tier is positioned in direct comparison with the Deere 310L. Deere knows the electric unit will be compared with the runtime of the diesel unit, which has a 34-gallon tank and typically provides more than a day’s worth of work. One positive for the electric machine: it has an outside-machine decibel level of 75 while the 310L runs at 89 decibels. “It doesn’t sound like a lot on paper, but it’s not as loud as my dishwasher,” Steger says.

Jordanne Waldschmidt, chief editor of Equipment World, caught up with Joe Dietz, the chief technology officer at excavation contractor Bob Dietz & Sons, New Paltz, New York, at the show. Dietz and his two brothers also serve as ambassadors for Deere, sharing their passion for the brand on social media. Here he gives his impressions after operating the 310X-tier for the first time:

CMSBrowserComponents.load({ el: ‘#vue-1633972535383-57’, name: ‘OEmbed’, props: {“mountPoint”:”/__oembed”,”url”:”https://youtu.be/Gf25ST98g6Y”,”attrs”:{“type”:”oembed”,”id”:”https://youtu.be/Gf25ST98g6Y”,”element”:”aside”}}, hydrate: false });

Hennings says utility companies, such as National Grid, along with municipalities working under emission mandates, are likely to be first adaptors of the 310 X-tier when it comes to market.

What we know now

John Deere

As mentioned, Deere compares the 310 X-tier with the diesel-powered 310L. It has a net peak power of 75 kilowatts (equivalent to 100 horsepower) at 1,600 rpm. The placard at the Utility Show posted 310 X-tier specs in line with those of the 310L:

14-foot 1-inch max dig depth.6,602-pound loader lifting capacity. 6,992-pound crowd cylinder digging force. 22.8 mph max travel speed.

One noticeable difference: the 310L has a listed operating weight of 14,669 pounds; for the 310 X-tier that gets bumped up to 16,119 pounds.

But again, these are just Phase 1 specs. “There will likely be many changes in the specs before it’s available for sale,” Hennings says.

John Deere announced in January that it had partnered with energy company National Grid an electric, natural gas and clean energy company serving more than 20 million customers in the Northeast to pioneer the machine.

At the time, Jason Daly, Deere global director, production systems, technology and marketing, called the project “another stepping stone in our backhoe innovation journey.” Adds Hennings: “This is an exciting project for the Deere backhoe design team.”

Did you miss our previous article…

https://constructionosa.org/?p=533

From Beaches to Bases, This N.C. Contractor Loves to Move Dirt

Two things you quickly learn about Matt Mitchell is that he loves Sneads Ferry, North Carolina, where he has lived all his life.

And he loves dirt.

“A grown man might be a grown man, but somewhere deep down he’s still got a little boy in him,” he says. “And they all like to play with little toys and dirt.”

“I love the challenges,” he adds, when explaining why he loves being a contractor. “I really like doing the things they say you can’t do, or can’t be done.”

That attitude has led his business, C.M. Mitchell Construction Company, to grow to more than 50 employees, 35 pieces of equipment and annual revenues of $10 million to $13 million. For that and more, Matt is one of Equipment World’s 2020 Contractor of the Year Award finalists.

Hard lessons

Matt learned about hard work, honesty and integrity from his father, a retired Marine who had been stationed at nearby Camp Lejeune. His father and mother ran a little country store and tackle shop on Vultures Landing.

“Son, your word is all you’ve got,” his dad would tell him.

He helped instill a strong work ethic in Matt.

“As a Marine, he taught us how to work, and he taught us what our backs are made for,” Matt recalls. “When I was growing up, it was all back-breaking work. He wasn’t taking any shortcuts.”

They would also dig the graves for local residents who passed away. It was a free service his father started, and Mitchell Construction continues it to this day.

As a teen, Matt worked for a family friend who owned a construction company. Matt would run a dozer and excavator and drive a dump truck. He worked for him for about 10 years. Then the owner had a heart attack and sold the business.

Matt bought a commercial fishing boat, but that new career lasted only about 10 weeks. “I was there one day fishing, and I just said, ‘I’m done with this. I’m going back in the dirt business. I’m going to do it myself.’”

That was in 1994. He used the money from selling the boat to buy a farm tractor and a trailer. His parents co-signed for a $25,000 loan. Matt used that money to buy a 1974 dump truck, a backhoe and a dozer.

His brother Mel drove the dump truck, and Matt moved dirt. They cleared lots, put in driveway culverts, whatever people needed done.

He did a lot of subcontracting work and landed his first big job at Camp Lejeune. During that job, he met Theresa who was working for the general contractor on the project. She helped him with the paperwork, and he told her if she ever decided to leave her job, he wanted her to come work for him.

“I don’t think you can afford me,” she told him.

But in time he won her over, and they’ve been keeping C.M. Mitchell growing ever since.

With her as chief financial officer and Matt running the construction business, they’ve landed many multimillion dollar projects over the years.

Landing big jobs

The company won its first job over $1 million by traveling to Virginia to meet with a large construction firm. The company was planning a complicated project involving a 100-square-foot amphibious boat ramp at Camp Lejuene. Matt convinced them he could handle the work.

“We were so excited,” recalls Theresa. “We had a $2 million job.”

With Matt running the construction operations and Theresa running the office, the couple have built a successful construction firm in Sneads Ferry, N.C.Equipment WorldThey began hiring more employees. Along with the boat ramp, the project involved building docks, ponds and a parking lot, as well as installing sewer and drainage lines.

The work was going well, but the finances ran into trouble. Mitchell wasn’t getting paid by the contractor on the project, and the company needed the money to pay off the project’s financing.

The contractor eventually paid the $800,000 he owed Mitchell. But the stress of trying to collect it had left Matt and Theresa rethinking their business. “One minute you’re up there, and the next minute you could lose your home if somebody doesn’t pay you,” says Theresa. The couple were also raising their three sons at the time.

After another episode in which they had to take a contractor to court to get paid, they decided to reorganize and trim down. “We’re going to stop going after the big work,” she says. “Let’s gain control of what we’re doing.”

They became more cautious about the contractors they subbed for. They landed work with large contractors, which brought them multiple projects. And they paid on time.

“We were able to pick and choose who we worked for,” Theresa says. “We could do some background on them and make sure that the people we were trying to be a subcontractor for were of good character.”

Then the September 11 terrorist attacks caused the local construction economy to tank. Mitchell was able make it through with projects on military bases. Government projects also got them through the Great Recession.

In 2011, the company had grown to 40 or so employees. And Matt decided to scale back to about 25 workers. He started turning some of his attention toward other ventures. He opened a restaurant and a boat store. He bought two shrimp boats. He bought and renovated boats and sold them. Then he spent about five years building his own boat – all while still running his construction firm.

“I don’t know why this was going on,” says Theresa. She calls it his “nostalgia tour.”

Matt just laughs.

“But one thing about my husband,” she adds. “He has no hobbies. Everything he does has to generate revenue.”

Ramping back up

Meanwhile, the construction firm was doing well, holding steady. And eventually, many of the side ventures drifted away.

“Our real passion that really drives us is here,” Theresa says, referring to Mitchell Construction.

Dump trucks haul in sand and an excavator fills dump trucks on the beach to rebuild dunes in North Carolina eroded by Hurricane Florence.Equipment WorldTwo of their sons love construction work, and the couple want the company to be available for them.

The company has grown back to 50 employees. It updated its accounting software, switched to project management software and began using iPads on jobsites. They also increased pay and benefits to attract and keep good employees.

Along with the changes, the company has continued to benefit from Matt’s work ethic and quality standards.

“A lot of people really respect Matt,” Theresa says. “A lot of his employees respect him because he’s the type of guy who is out there in the ditch with them.”

The company also maintains a family atmosphere. Theresa cooks lunch each day at the office for employees. A number of the employees are actual family members.

Their oldest son, Mark, has worked with them since 2000 and recently branched out on his own to start a concrete business. Their youngest son, Matthew, is the company’s asphalt division supervisor. Matt’s two brothers and Theresa’s sisters also work for the company.

“We’ve always been a real tightknit family,” Matt says.

Moving dirt

One of Mitchell’s latest projects has been rebuilding the sand dunes on Surf City and North Topsail beaches, which had eroded during Hurricane Florence.

The projects involved hauling in and placing more than 200,000 cubic yards of sand. Mitchell dump trucks came and went hauling sand from miles away, while excavators and dozers moved like clockwork to build the dunes.

“I can move dirt, and I love moving dirt,” Matt says.

Surf City Town Clerk Stephanie Hobbs agrees.

“They’re a great company,” she says. “I would give them the highest rating you have. They show up in a timely manner and get the job done on time and on budget.”

Matt attributes his success to hard work and recommends the same for new contractors.

“You’ve got to work hard. You’ve got to put your time in,” he says. “When everybody else is off having fun, you’ve got to go make a deal with somebody.”

C.M. Mitchell Construction dozers rebuild dunes damaged by Hurricane Florence.Equipment World

Did you miss our previous article…

https://constructionosa.org/?p=528

Diesel Prices Jump as Crude Oil Hits Highest Price Since 2014

Increased demand amid the easing of the pandemic and OPEC+ supply limitations have caused the price of diesel to jump 10.5 cents in the past week. The average retail price of a gallon of on-highway diesel soared to $3.47 during the week of October 4, according to the U.S. Department of Energy’s Energy Information Administration. That’s $1.08 higher than just one year ago.

The nation’s most expensive diesel on average is in California at $4.369, while the least expensive diesel on average is $3.203 a gallon in the Gulf Coast. The Midwest region saw the nation’s highest one-week increase at 10.4 cents. The smallest one-week increase was 3.0 cents in California.

The Biden administration has urged OPEC+ to increase production and is considering releasing crude oil reserves to cool prices. U.S. West Texas Intermediate crude oil hit its highest price since 2014 at $81.06 per barrel. Crude oil accounts for 49%t of the cost of a gallon of diesel.

Price increases this fall were also impacted by storm damage. Several refineries in Louisiana are still preparing to restart after flooding and power outages caused by Hurricane Ida. Louisiana’s 17 oil refineries account for nearly one-fifth of the nation’s refining capacity and can process about 3.4 million barrels of crude oil per day, says the U.S. Energy Information Administration.

Complete diesel price information is available on EIA’s website.

Diesel prices are up more than $1 per gallon compared to one year ago.U.S. Energy Information Administration

Did you miss our previous article…

https://constructionosa.org/?p=520

Where Do Things Stand with the Infrastructure Bill and Transportation Funding?

Since the Senate’s passage of a $1.2 trillion infrastructure bill in August, negotiations have taken a turn for the partisan worse in the House.

What once seemed to be a bipartisan effort to enact the largest spending increase for infrastructure in decades has devolved into last-ditch efforts to just keep current transportation funding levels intact – but only for one more month – and to prevent the entire federal government from shutting down, at least until December 3.

What happened?

The Infrastructure Investment & Jobs Act passed the Senate August 10 in a bipartisan 69-30 vote. It includes $550 billion in new funding over five years as well as reauthorizes increased transportation funding through 2026.

Though the bill had bipartisan support in the Senate, House Democrats wanted the bill paired with a $3.5 billion package of Biden administration initiatives called the Build Back Better Plan. The plan focuses on such measures as pre-kindergarten, paid community college tuition, expansion of Medicare and addressing climate change.

House Democrats demanded that the Senate also pass that bill before it would take up the infrastructure legislation. In a party-line vote, the Senate set up the bill for a process known as reconciliation in which it could pass by a simple majority. Democrats do not have the votes to pass the legislation under the Senate’s current rule of 60 “yes” votes to pass legislation, and it’s not likely the plan would pass with reconciliation.

When the infrastructure bill and Build Back Better Plan came to the House, Republicans and liberal Democrats balked, with most of the disagreement on the Build Back Better Plan. Scheduled votes on the infrastructure bill in September and in October were pulled as there were not enough votes to pass it.

The current schedule is for the House to vote on the infrastructure bill by October 31. President Joe Biden and House Democrats have maintained that the Build Back Better Plan must be negotiated before the infrastructure bill can pass.

Meanwhile, on October 1, federal funding for state road projects and other surface transportation expired. Thousands of federal transportation department employees were furloughed. The next day, the House and Senate passed a one-month extension of the transportation funding. The employees returned and funding resumed – but only until October 31.

While all of this was going on, the country was also running up against an October 18 deadline to raise its debt limit or face default. Senate Republicans said this was the Democrats’ responsibility, and they should extend the debt limit via the reconciliation process that would require a simple majority. Democratic senators said there was not enough time to enact reconciliation and that in the past raising the debt limit had been a bipartisan function.

On Thursday, the debt-limit crisis was temporarily averted when a compromise passed the Senate to raise the debt ceiling by $480 billion until December 3.

What’s next?

The focus in Washington now centers on the Build Back Better Plan and reducing its $3.5 trillion pricetag to one that Democrats can agree on. Biden has suggested $2 trillion, while swing-vote Senator Joe Manchin (D-W.Va.) is saying $1.5 trillion is the most he could support.

Construction industry and business groups are urging Congress to pass the infrastructure bill and separate its consideration from the Build Back Better Plan, which also includes an increase in the corporate tax rate.

“AGC is very disappointed that this historic investment in our nation’s infrastructure has yet again been delayed, and will continue calling on the House to pass the Infrastructure Investment and Jobs Act as soon as possible,” says a statement from the Associated General Contractors.

AGC says it will push the House to pass the infrastructure bill “and stop using construction companies and their workers as political leverage for the Build Back Better plan.”

“There should be no linkage between IIJA [Infrastructure Investment & Jobs Act ] and the reconciliation bill,” says the Associated Equipment Distributors. “AED will also continue to work with our industry partners in strong opposition to increasing taxes and onerous regulations on America’s job creators.”

Transportation associations are also concerned about funding for state surface transportation programs, which will again expire at the end of this month.

“Short-term extensions are not a suitable way to govern,” says Jim Tymon, president of the American Association of State Highway and Transportation Officials. “AASHTO remains focused on the passage of a long-term surface transportation bill to ensure the delivery of a safe and efficient multimodal transportation system, and we urge Congress to do the same.”

The American Road & Transportation Builders Association, along with the 32 other members of the Transportation Construction Coalition, recently wrote to Republicans and Democrats who oppose the infrastructure bill urging their reconsideration.

The letter disputes Republicans’ assertions that the bill is simply a tactic to enact the Build Back Better Plan.

“This legislation, on its own, would increase every state’s highway formula funding by an average of 35 percent,” the TCC letter says. “These significant investments will immediately begin to create new, well-paying careers and improve our nation’s roads and bridges, which will increase productivity and economic competitiveness for decades to come.”

What’s at stake?

The infrastructure bill would add $488 billion to the U.S. economy by 2027, with just the additional $153.7 billion slated for new highway, bridge and public transit investment, according to ARTBA.

Citing an analysis by IHS Markit, ARTBA says the transportation investment would also create 250,000 new jobs by 2025, with half being outside the construction industry.

An S&P Global report estimates the entire infrastructure package would create 880,000 jobs over the next decade, particularly middle-class positions in construction, engineering, transportation and energy, and would boost the overall economy by $1.4 trillion over eight years.

Here are some highlights of the additional $550 billion in spending over five years included in the infrastructure bill approved by the Senate:

Roads, bridges, major projects – $110 billionPower infrastructure – $73 billionPassenger and freight rail – $66 billionBroadband infrastructure – $65 billionDrinking water infrastructure – $55 billionPublic transit – $39 billionAirports – $25 billionPorts and waterways – $17 billionTransportation safety – $11 billionElectric vehicle infrastructure – $7.5 billionElectric buses and transit – $7.5 billionReconnecting communities split by highway projects – $1 billion

Did you miss our previous article…

https://constructionosa.org/?p=502

“Minimum Swing with Maximum Space”: JCB’s New 245XR Excavator

JCB has expanded its X Series of excavators with the reduced tailswing 28-ton 245XR while maintaining the lineup’s spacious cab.

Between 2018 and 2019, JCB rolled out five X Series excavators. But Tim Burnhope, chief innovation and growth officer, said there was still something missing in the line. As infrastructure needs and funding have grown, more contractors are finding themselves on tighter jobsites.

“We needed to complement our existing conventional tailswing models with a reduced tailswing model, a machine that could [operate] safely in urban settings, on utilities jobsites and on road construction projects,” Burnhope says.

That led JCB to develop the 5-foot 8-inch tailswing model, which has 40% less tail swing than its sister model the 220X. At 28 tons, the 245XR weighs 2 tons more than the 220X. JCB says it gave the 245XR an extra 2 tons of counterweight, and it recessed the counterweight to protect the rear end from impact damage.

JCB designed the reduced-tailswing 245XR excavator for such tasks as roadwork beside traffic.JCBThe next challenge was to reduce tail swing without sacrificing any space for the series’ standard Command Plus cab. JCB reports that the operator station is the same size as the 220X at 39 inches wide and 100 cubic feet of volume, delivering what it calls “minimum swing with maximum space.”

To achieve the same performance, the company developed what it calls its strongest ever boom. The standard boom is composed of one piece for strength and lighter weight, according to Burnhope. A triple-articulated boom is optional.

A dipper-arm choice of 94 or 118 inches is offered. Dig reach with the mono boom is 31 feet and dig depth is 22 feet. The turntable rated at 26 tons is designed to increase digging force while distributing the force throughout the undercarriage, says Adrian Hall, heavy excavators product general manager.

The 245XR is equipped with heavy-duty track pads of 600 to 900 millimeters for “exceptional stability,” Burnhope says. A dozer blade is optional.

The JCB 245XR excavator’s dig reach with the mono boom is 31 feet and dig depth is 22 feet.JCBThe new excavator – along with all of the five other models in the X Series – gets a new JCB Stage V engine. Stage V is the new European emissions standard. The 245XR runs on a 172-horsepower JCB 448 diesel engine. Stage V and Tier 4 Finals emissions standards are achieved by selective catalytic reduction, diesel particulate filter and diesel oxidation catalyst.

Burnhope says the new engine does not require exhaust gas recirculation. He also says the new engine burns cleaner than the former diesel engine on the 220X, but delivers the same amount of torque of 708 foot-pounds. It also consumes 5% less fuel than the former Tier 4 motor, he says.

The engines now also feature auto-stop and auto-idle as standard to reduce fuel consumption and emissions when not in use.

JCB designed the excavator’s hydraulics for precise, smooth movement. The system features the latest Kawasaki pumps and Kayaba main control valve. The diameter of the hydraulic hose has been increased to improve hydraulic flow for increased performance and efficiency, Burnhope says.

JCB kept the same Command Plus cab on its other five X Series excavators on the reduced-tailswing 245XR.JCBThe full-size Command Plus cab is equipped with a variety of seat choices, including one with built-in heating and cooling and electric lumbar support. Standard cab features include rear and side cameras, heating and air, and Bluetooth integrated into the 7-inch control screen. The cab has double cushion viscous mounts to reduce vibration, and interior noise to 69 decibels. The joystick and switch controls are mounted to the seat and move with the operator.

JCB also placed the 245XR’s main service points in one ground-level compartment that is accessed by a large swing door. The company increased service intervals to 2,000 hours for air and hydraulic filters, and to 500 hours for engine oil.

Quick Specs

Max bucket capacity – 1.63 cubic yardsMax operating weight – 60,184 poundsHorsepower – 172Tail swing – 5 feet 8 inchesTravel speed – 1.99 to 3.54 mphMax digging reach (mono boom) – 32 feet 1 inchMax digging depth (mono boom) – 21 feet 9 inches

From Brooms to Blowers, 11 Attachments for Clearing Snow

Winter weather is close at hand, so it’s time to start thinking about snow-clearing equipment.

Contractors have a variety of attachments to choose from to equip their construction equipment or pickup trucks to remove snow and ice from roads, parking lots and other surfaces.

Here are 11 attachments to consider:

Bobcat’s hydraulically driven angle broom attachment (pictured above) can handle quick cleanup jobs without damaging pavement surfaces. The bristles’ waved design creates a cleaner path and can sweep more snow or debris in one pass. Reverse bristle rotation is available on the 68- and 84-inch angle brooms for sweeping leaves, snow and debris away from corners, curbs, buildings and obstacles. The standard orange heavy-duty bristles are designed for longer life and better visibility. The attachment is available for Bobcat’s M and R series compact track loaders and skid steers and Bobcat Toolcats.

Doosan snow pusherDoosanDoosan’s bucket-mounted snow pusher attachment is designed for the company’s 13- to 20-metric-ton wheel loaders and toolcarriers. The attachment comes in two versions: 12 feet wide at 2,200 pounds and 14 feet wide at 2,400 pounds. The pusher is designed to be an alternative to buckets and traditional plowing for clearing parking lots and roads. Features include a 47-inch moldboard for high-capacity snow removal, a 1.5-inch rubber cutting edge to protect surfaces, high-grade steel skid shoes, a 12-inch push beam and three bucket-mount support tubes to help keep the snow pusher rigid.

Fisher Storm Boxx snow pusherFisherFisher made its Storm Boxx pusher plows for large construction equipment, such as wheel loaders and backhoes. Models are available at 12, 14 or 16 feet wide. A two-piece steel trip edge is designed to deliver a cleaner scrape of hardpacked snow and ice. It also protects the operator and equipment when hitting hidden obstacles. Floating attachment plates allow side-to-side movement and smooth out bumps, keeping the pusher in continuous contact with the surface. It is also designed to be easily attached to various equipment.

Hilltip salt spreaderHilltipHilltip’s new IceStriker 2000-3300 SSA/SSC stainless-steel salt spreaders are designed for three-quarter-ton trucks. The device can spread bulk sand and gravel, bulk/bag salt, sand-salt mixes and fertilizers. It is offered in three sizes: 2, 2.65 and 3.3 cubic yards. The stainless steel wards off corrosion, and Hilltip also immerses its hoppers in an acid bath to ensure corrosion-free welds and surfaces. An inverted “V” with a vibrator helps prevent bridging. The stainless-steel flip-up chute is designed to spread salt in environments with high humidity, and a tarp kit helps keep spreading materials dry.

HitchDoc hydraulic snow blowerHitchDocHitchDoc’s all hydraulic snow blower is designed to reduce your carbon footprint. The company has eliminated the diesel engine, crankcase, shear pin and air filter, as well as the need for diesel exhaust fluid. The hydraulic blower is quieter and offers better visibility and balance. It is 9 feet wide and weighs 5,200 pounds. It is designed for wheel loaders of 2 to 4 cubic yards equipped with hydrostatic transmissions.

JCB Snow BlowerJCBThe JCB snow blower range features a two-stage design with the ability to throw snow 25 to 40 feet. A poly-lined chute and deflector can be adjusted to direct the snow discharge. The 25-inch standard flow shroud openings quickly dispense with high volumes of snow. The direct drive hydraulic motor design reduces the number of moving components for less wear and longer life. The blower includes adjustable skid shoes, a bolt-on replaceable wear-resistant tapered steel edge and quick release coupling. It is available in widths of 60, 72, 78 and 84 inches in either standard or high flow.

Pettibone SpeedSwing 445F with snowblowerPettibonePettibone’s Speed Swing 445F rail crane is now available with a CreepDrive system from Poclain Hydraulics that allows it to run high-flow attachments like snow blowers and power brooms at slower travel speeds on or off the rails. The CreepDrive can deliver up to 33 gallons per minute of hydraulic flow. It comes with a display interface for controlling rpms and an integrated rocker pedal for traveling the machine forward and in reverse up to 2 mph. The Speed Swing 445F provides 180-degree boom rotation and has a spacious, climate-controlled operator cab.

SnowEx heavy-duty snowplowSnowExSnowEx’s heavy-duty straight-blade snowplow gives skid steers commercial-contractor performance. It is available in four blade widths. The plow is built with a formed base channel for extra durability. Six vertical ribs, two angled Power Ribs and a quad design provide added torsional strength to prevent blade twisting. The A-frame is constructed of tubular steel to handle the toughest jobs.

Virnig picukp broom with water tankVirnigVirnig’s Internal Water Tank Broom for skid steers controls dust as you sweep. The protected 55-gallon tank behind the bucket provides 35 minutes of continuous runtime. The translucent tank has capacity indicators so water level can be viewed by the operator while in the cab. The guarded adjustable valve regulates water pressure to the nozzles. The broom is available in 72 or 84 inches. Features on the broom include a recessed and guarded direct drive motor, HD bucket with wear bars, bolt-on edge, oversized 2-inch bearing, poly/wire bristles and pin adjustment system.

Western’s Prodigy Skid Steer SnowplowWesternThe Prodigy snowplow from Western features wings that automatically move with no additional wiring or controls. It has a universal skid-steer mounting plate. Once the pins are engaged, the plow is ready. The plow uses the onboard hydraulics system of the skid steer to lift and lower the blade. An oscillating mount that provides 6 degrees of total side-to-side oscillation is optional to improve scrape and cutting-edge wear while reducing damage to the terrain.

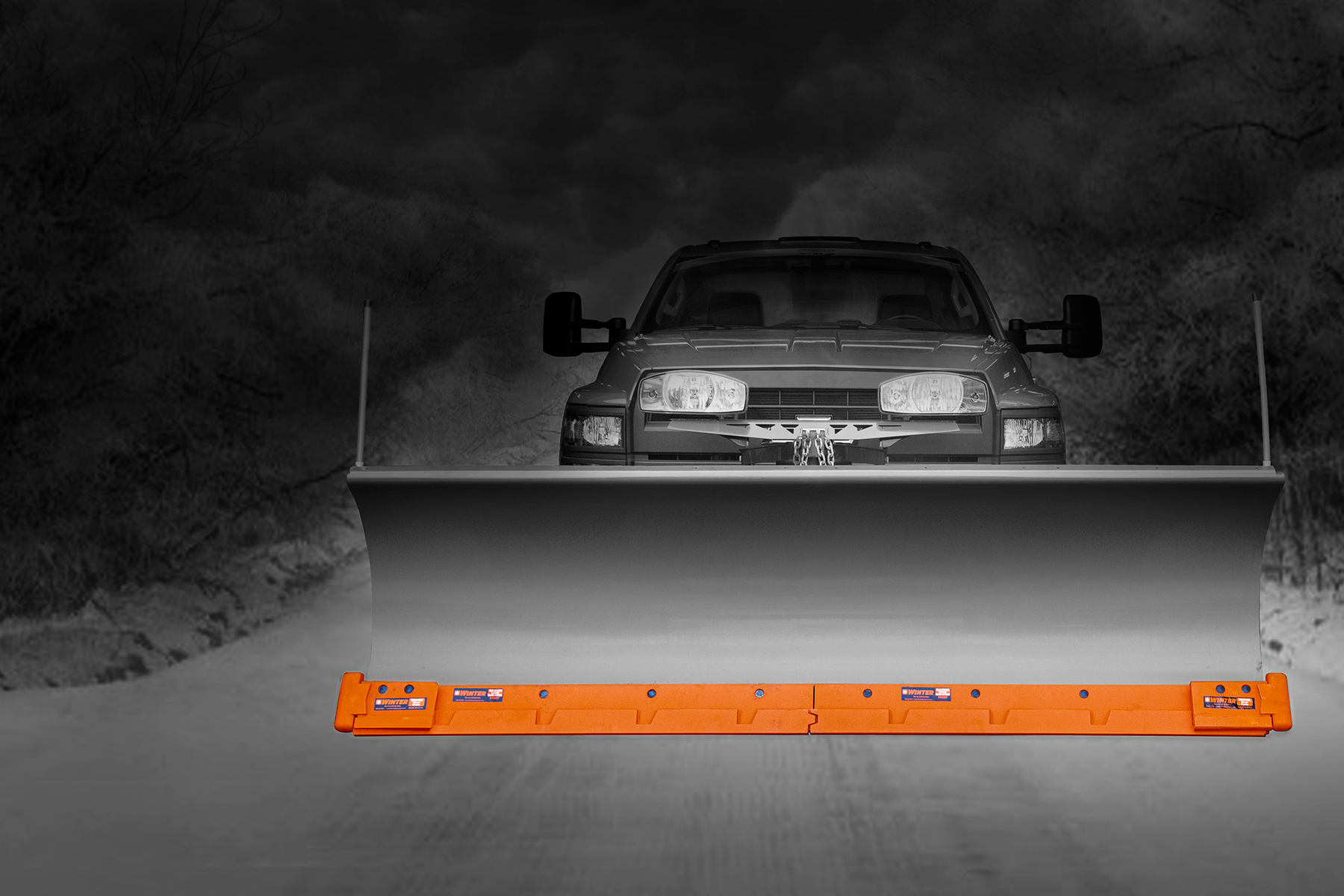

Winter Equipment Razor Arrow snow bladeWinter EquipmentWinter Equipment’s Razor Arrow Straight Blade System is designed to give Western Pro Plus plows longer blade life and improve cutting. It features two, 4-1/2-foot Razor blade sections, two Plow Guard Juniors and grade 8 hardware. The two Plow Guard Juniors prevent uneven and premature wear on the plow’s wear bar. The Razor Arrow system includes a two-piece, pre-welded blade with 5/8-inch abrasion-resistant cover plates. The cover plates are welded to a tungsten carbide insert cutting edge for increased wear life and surface footprint. Built-in wear indicators help to track wear life.

Did you miss our previous article…

https://constructionosa.org/?p=468

Industry Roundup: National Equipment Dealers buys Richardson

National Equipment Dealers (NED) has bought Richardson Service 1991, expanding its organization in South Carolina.

Based in Conway, South Carolina, Richardson specializes in construction, forestry and compact equipment and will now represent Hyundai Construction Equipment, Manitou, Sakai, Yanmar and Bell.

The former Richardson branch will be the first location among NED companies renamed as NED. Over the coming months, NED will rebrand the remaining MAY-RHI, Earthmovers Construction Equipment and Four Seasons branches to NED.

Through Richardson, NED gains the Berko, CMI and Prinoth lines. The entire Richardson team will remain with NED.

F&W adds Ransome Attachments

Pictured are (from left): Eric Ransome and Barbara Freund of Ransome Attachments, and Matt Valentine and Mark Laigle of F&W.Ransome Attachments

F&W Equipment has added the complete line of attachments offered by Ransome Attachments, including its Exac-One Mini Mower and Black Splitter S2 800 Cone Splitter.

F&W also offers Kubota compact and mid-size farm and landscaping equipment, Doosan excavators, wheel loaders and compact equipment, as well as other specialty equipment.

Maverick joins Morbark

Maverick Environmental Equipment has been named a Morbark Industrial Products dealer for Ohio, Indiana, Kentucky and western West Virginia. Maverick has locations in Newbury and Bremen, Ohio, with a focus on aggregate processing, waste recycling, forestry and biomass.

H&E completes crane sale

H&E Equipment Services has completed the $130 million cash sale of its crane business to Manitowoc. H&E says it will use the funds for facilities expansion, rental fleet investment and general corporate purposes.

“We believe our transition to a pure rental business strategy should result in improved revenues and margins through the industry cycle,” says Brad Barber, H&E CEO.

H&E also sold two earthmoving distribution branches in Arkansas, and will remain a distributor of earthmoving equipment in Louisiana. The company now has 101 branch locations in 24 states.

SMH Group adds Wood’s CRW

Wood’s CRW is now a dealer for Atlas material handlers, owned by SMH Group US. The Atlas line includes mobile industrial machines and industrial tracked machines for the scrap, wood and recycling markets, among others.

Based in Williston, Vermont, Wood’s CRW has four locations with coverage in all or part of eight states. It offers Volvo Construction Equipment, Link-Belt cranes and excavators, National cranes and Mecalac product lines.

15 Proven Ways To Recruit Construction Dealer Techs

The ever-present dealer technician shortage had us thinking it might be a good time to revisit some of the best construction equipment tech recruiting tips we’ve received from dealers and rental companies.

1.Go to where the gearheads hang out. This can include truck mud-runs and local motorsports events. Sponsor an involved employee or a car and invite current employees to attend think of them as your ambassadors. While you might not find a trained diesel tech in the audience, many of the attendees will have a mechanical interest. Your sponsorship may give you access to this community plus build retention among the techs you already have.

2. Think beyond just out of high school. Those fresh-faced 18-year-olds may not be your only hope. Some argue that those with more years and more life experiences may be also be prime targets, especially if they’re only making $16 an hour in an Amazon warehouse. Those who have started families may be receptive if you lay out a career path and a smart diesel tech these days most assuredly has a career path.

3. Get good at social media. Yes, this is obvious, but do you really practice it? Consistent posting is the name of the game. Create a social media plan and execute it. Put up regular posts of your employee’s jobs, milestones and success stories, and encourage them to do the same. If a technician completes a rebuild on a big engine, for instance, the selfie they take might detail how they overcame the challenge. His or her share full of the pride of accomplishment about work done at your company could in turn gain an audience. And it will remind people that you’re a great employer.

4. But don’t dismiss the tried and true. Traditional methods can still hold sway, including help-wanted signs on company property or trucks, word of mouth and employee referrals. Many employers swear by the referrals they get from current employees because employees know a bad referral will reflect poorly on them. And always ask job candidates how they heard about your company and keep track of which methods work.

5. Be aware of the digital tools available to you. Find out how you can target an online audience. Look into geotargeting and targeted data sets and know what works in terms of setting up your online ads and landing page(s). You can target people on Facebook, job boards and through search-engine marketing. And be transparent in your messaging. This includes being direct about base pay, hiring and relocation bonuses as well as highlighting company culture. Have a timely lead followup in place; ideally respond within 5 minutes by phone after a lead comes through.

6. Make sure you’re inviting to women and minorities. Realize that diversity inclusion and workforce development are closely intertwined. When you do a bad job at tapping into diverse groups, you are more likely to have a workforce problem. Explore local groups that can help you reach out to specific communities.

7. Grow your own. It’s difficult to hire off the street and there are not enough tech school grads to fill the need. One neglected area may be right in your back yard. Make sure your own techs know about the opportunities you are bragging about to the outside world and encourage them to advance.

8. Up the ante. Sometimes it is a money/benefits game. Assess what you’re offering compared with all local employers, not just the ones who are your direct competitors. One rental company offers to match a certain percentage of an employee’s student loan payments up to $30,000 — and they don’t require a period of employment before the reimbursements begin.

9. Have a recruiting plan. If you’re proactive with your recruiting strategy you won’t have to hire out of desperation. And don’t stop. Actively recruit even if your shop is currently at capacity. Set a goal of tech interviews to be accomplished in a certain time period. Consistently evaluate what works and what doesn’t.

10. Celebrate incoming tech interns. Several tech schools and dealerships have set up “signing day” events such as those conducted for celebrated college athletes. It helps solidify the intern’s commitment and gives them the vision and knowledge they have an official spot.

11. Emphasize the career runway. Candidates have to earn the next rung on the ladder and there are going to be long hours, hard work, grease and dirt involved. New hires are not going to get a $70,000 job right out of tech school. But let them know there is a career runway and there are many paths up from the shop floor. These include the emerging technical expert who guides customers on the best way to employ today’s machine control solutions.

12. Hire a hero. The Reserves and National Guard are sweet spots for recruiting because their units are all locally based. These “weekend warriors” pull one weekend of active duty service a month and one two-week mission a year. The rest of the time they are civilians. While not all Reserve or Guard units have mechanics or technicians a high percentage have motor pools. In addition to a scholarship, one rental company pays the gap between discharge and when the G.I. Bill benefits take effect, providing around $1,200 to help cover living expenses. And be sure to spend time at any recruiting and career fairs at military bases in your area.

13. Take back the high schools. Don’t assume that local guidance counselors know that there are high-paying jobs that go unfilled in their local area. One company wrote to 3,500 guidance counselors and educators in its state, and received several “we didn’t know” responses. One dealer goes on more than 80 high school visits a years to connect with students in three states. Another dealer makes presentations on how to research and choose a career that’s only tangentially about diesel tech careers. Educate the people who are at your back door.

14. Don’t forget the parents. Take a cue from the recent U.S. Army ad campaign you’re looking for a few good parents, ones that see the open technician field as a great opportunity. Host an event at your shop and invite the parents along with the students. Have your techs show what it’s like to work on heavy equipment. Recruiting talent is no different than a college football coach coming into someone’s living room and telling the parents that when they come to you, you’ll make sure they do well.

15. Never stop recruiting. Adopt some tactics floating in automotive circles. Have a business card with your elevator pitch on it, outlining the top three reasons why people should work for you. Or make it simple: show a piece of construction equipment with text that reads, “Your next job here” with your contact info. Hand them out with a comment such as, “I’m Joe and I hire diesel technicians.”

Did you miss our previous article…

https://constructionosa.org/?p=456

I-49 Missouri-Arkansas Connector Now Open for 290 Miles

Another link in the planned six-state I-49 has been completed with five miles of roadway opening between the Arkansas and Missouri border.

The project’s completion leaves a 290-mile interstate route from Kansas City, Missouri, to Fort Smith, Arkansas. The last five miles of the connector opened October 1.

The I-49 and I-29 corridor will also eventually pass through Louisiana, Iowa, South Dakota and North Dakota, stretching for 1,600 miles and connecting at I-29 in Kansas City. Plans are to add links to New Orleans area ports.

I-29 extends from Kansas City to Winnipeg, Canada. The eventual goal is to provide an uninterrupted Interstate Trade Corridor from Canada to New Orleans and into Central and South America to the Panama Canal, according to the I-49 International Coalition.

Transportation officials in Arkansas and Missouri say they have been discussing the connector for more than 25 years. Construction has progressed in phases.

Shaking hands, from left, are Arkansas Governor Asa Hutchinson and Missouri Governor Mike Parson at the ribbon cutting for the last section of the I-49 Missouri-Arkansas Connector.Missouri Department of TransportationThe final five miles were built between Pineville, Missouri, where construction ended in 2012, and the Arkansas state line.

The project involved building a four-lane divided highway west of Route 71. Access to the newly designated interstate section is only by interchanges. A new interchange was built at Missouri Route 90 west of Jane. Five bridges were also constructed.

The project’s estimated cost was $70.3 million.

“This high-quality roadway will help promote tourism, business investment and workforce opportunities between our two great states,” said Missouri Governor Mike Parson.

Did you miss our previous article…

https://constructionosa.org/?p=450

Vanair Debuts EPEQ Battery-Powered Truck-Mounted Compressor Line

Vanair unveiled its new electric battery-powered product line for its truck-mounted air compressors and other equipment at this year’s Utility Expo in Louisville, Kentucky.

The new EPEQ equipment allows you to turn off the truck’s engine while running tools and equipment, releasing no emissions from the power source. Prior to the EPEQ debut, Vanair’s products have been PTO-driven off the truck’s chassis, hydraulic driven or they had their own combustion engine.

The heart of the Electrified Power System is the company’s new ELiMent lithium-ion phosphate battery. The system can be mounted on or within combustion-engine vehicles, electric vehicles and trailers.

Along with zero emissions, the EPEQ system reduces noise, heat and weight, while also reducing maintenance and overall vehicle costs, the company says.

The ELiMent battery system can discharge power at the same time it is being charged. ELiMent batteries can power electric-motor driven air compressors, electric-hydraulic power, AC power inverters, welders and electric-driven above-deck air compressors, among other devices.

The 48-volt battery system delivers 5 kilowatts of power. It is designed to be plug and play and mobile, as a 13-inch cube weighing 95 pounds versus a lead-acid battery setup of about 300 pounds and 3 feet. The company says it also plans to soon launch a 48-volt, 7.5-kilowatt version.

The Vanair EPEQ Air20 air compressor is powered by the company’s new battery and doesn’t use the truck’s engine to run.VanairAlong with the new battery system, Vanair displayed its new EPEQ Air20 reciprocating air compressor. The compressor produces 20 cubic feet per minute at 150 psi. It is designed to run such tools as an impact wrench. Vanair says it delivers a 20% efficiency gain for longer battery life.

Vanair also unveiled its EPEQ Air45 air-on-demand rotary screw compressor. It produces 20 to 45 cubic feet per minute for running a 1-inch impact wrench, inflating tires and similar functions.

The company also displayed a truck-mounted above-deck compressor powered by a 300-volt, 30-kilowatt ELiMent battery. The compressor produces 160 CFM at 250 psi.

Other products unveiled at The Utility Expo included:

An EPEQ welder with an integrated battery pack inside it. It weighs 33 pounds. A 48-volt, 5-kilowatt alternator, which allows you to charge the ELiMent battery while the battery is discharging. The alternator can be mounted under the vehicle.An EPEQ 3,000-watt inverter that can take a 48-volt input and put out 120 volts on the vehicle.An EPEQ 5,000-watt inverter that is stackable. So if you add two, then it can work like a 10,000-watt inverter and so on.

The company says all of these devices will communicate with its battery management system.

Did you miss our previous article…

https://constructionosa.org/?p=447