Home » Articles posted by Tessa Sanderson (Page 19)

Author Archives: Tessa Sanderson

D.C. DOT Opens Triple-Arch Frederick Douglass Memorial Bridge

Vehicles can now travel the new Frederick Douglass Memorial Bridge in Washington, D.C., marking the end of the largest construction project in the District Department of Transportation’s history.

Work began in 2018 on the triple-arch bridge over the Anacostia River. It replaces a 70-year-old bridge to provide an updated link between Maryland and D.C. It is part of a program to improve safety and traffic on the I-295/D.C. 295 corridor. The next phase involves reconstructing the Suitland Parkway/I-295 interchange.

A year ago, the city celebrated the last piece of the final arch being placed. The new bridge is 100 feet parallel to the old bridge, which has been traveled by 77,000 vehicles a day, mostly of Maryland commuters to D.C. It was deemed to be functionally obsolete. All traffic had been shifted from the old bridge to the new one by September 12.

The Frederick Douglass Memorial Bridge in Washington, D.C., being prepared for its opening.District Department of TransportationAlong with the arches, features on the new bridge include four pedestrian overlooks and two piers that appear to float on the river. Six lanes of traffic now span the bridge, as well as new biking and walking paths.

The contractor for the new bridge consists of a joint venture of Archer Western Construction and Granite Construction companies. AECOM is the lead designer, and HNTB is assisting the District Department of Transportation with program and construction management.

Check out this DDOT video of the final arch piece being installed:

CMSBrowserComponents.load({ el: ‘#vue-1631565679529-141’, name: ‘OEmbed’, props: {“mountPoint”:”/__oembed”,”url”:”https://youtu.be/zPzxs1Ausg4″,”attrs”:{“type”:”oembed”,”id”:”https://youtu.be/zPzxs1Ausg4″,”element”:”aside”}}, hydrate: false });

Did you miss our previous article…

https://constructionosa.org/?p=253

When a Compact Loader Just Won’t Do: Wheel Loaders Still Hold Sway on Jobsite

Though compact loaders continue to gain in popularity, standard wheel loaders are still a staple on the jobsite, thanks to their heavy-duty loading abilities.

But just as their compact equivalents are becoming more versatile and adding new technology, so too are these trusty workhorses.

The newest models are coming with such features as obstacle detection, tablet-like touchscreen displays and a variety of attachments.

Juston Thompson, senior product manager, Hyundai Construction Equipment Americas, says machines up to 3.5 cubic yards are more likely to be used with attachments such as mulchers, buckets with thumbs or grapples, and rakes. “Compared to compact equipment, small- to mid-size wheel loaders offer more capacity in these applications,” he says.

And speaking of buckets, one manufacturer has even come out with a “transparent” one, using advanced technology that enables the operator views into the typical blind spots.

For customers considering a wheel loader in addition to or instead of a compact loader, John Dotto, product application and training specialist, Wacker Neuson, suggests three key considerations:

First, is the wheel loader compatible with the attachment now in use or projected for future use?

Two, can you trailer a wheel loader, which is likely longer, wider and taller than a skid steer?

Three, given that the learning curve to operate a wheel loader is shorter than for a skid steer or compact track loader, is that an advantage for your operation? If you have frequent turnover and often have lesser-skilled operators, the relative simplicity of a wheel loader can be a real advantage.

Here’s a look at the latest models and features from some of the top manufacturers:

Cat’s new models

The new Cat 980 and 982 have Cat Payload, which includes low-lift-weigh and manual tip-off functions. Optional Cat Advanced Payload adds Lists-Management, Multitask- and Manual-Add Modes and Tip-off assist.

The 980 XE and 982 XE models have continuously variable transmissions, the first in this size class. The design uses a direct mechanical path from the engine to the wheels with a Hystat variator and can improve fuel efficiency up to 35%.

The 980 and 982 models have 1,000-hour maintenance intervals. Remote Troubleshoot allows remote diagnostics, while Remote Flash ensures machines are running the most up-to-date software. Customers can install updates at the best time for their operations through the Cat Remote Services Web Portal.

With Autodig, the entire bucket loading cycle can be automated, while Autodig with Auto Set Tires can significantly reduce tire slip.

Doosan’s “transparent bucket”

Cabs on the new -7 Series machines from Doosan have 14% more glass, improved HVAC airflow and an adjustable 8-inch monitor with integrated rear-camera view.

All Doosan -7 Series wheel loaders have the same cab layout with important and frequently used controls relocated for more intuitive access, a standard variable-speed, reversible fan that is adjustable from the Doosan Smart Touch screen, an optional automatic lubrication system and the Doosan Smart Guidance System that helps operators improve their efficiency.DoosanDoosan’s Situation Awareness Technology (SAT) 2.0 monitors multiple systems to provide optimal performance and fuel efficiency. The operator can tap a button or push the accelerator past a detent to move up one mode (Economy to Normal or Normal to Power).

Doosan’s Transparent Bucket uses one camera mounted low on the frame and a second mounted high on the cab. Software stitches together the two views to enhance visibility in front of the bucket. The system also has object detection.

Transparent Bucket can be retrofitted to existing machines with a kit that includes a monitor and an electronics module that interfaces with the loader’s CAN bus.

“Doosan is working toward our Concept-X integration and automation of the worksite,” says Aaron Kleingartner, dealer and product marketing manager, Doosan Infracore North America. “Our Transparent Bucket feature fits right in with that.”

Customer feedback drives Case updates

Case G Series loaders have updated features including a tablet-like touchscreen display, configurable buttons in the armrest, adjustable electrohydraulic controls and a fully integrated OEM payload system that improves load accuracy and provides detailed reporting.

Case G Series loaders have a new touchscreen display that provides machine information and convenient access to operational controls, a new Smart Power Mode with enhanced communication between the engine and transmission to improve fuel efficiency and reduce wear, and enhanced telematics and integration with the Case North American Uptime Center.Case CEAlso new is the tire pressure monitoring system that shows pressures on the display and issues an alert for out-of-range readings. Power modes have been reduced to two: Smart and Max.

“These features came from feedback from customers and dealers,” says Andrew Dargatz, product manager, Case. “The result is increased productivity and uptime with decreased operational elements that hinder performance and profitability.”

Mecalac goes bigger

The AS1600 swing loader has been Mecalac’s only non-compact model. The company is now bringing its larger AS210 swing loader to North America.

The AS210 is Mecalac’s largest swing loader. Bucket capacity range is 2.7 to 3.9 cubic yards. Operating weight is 33,069 pounds. It is powered by a Deutz turbo diesel engine rated at 175 horsepower. Dump height is 134 inches. Turning radius is 16 feet 4 inches, thanks to four-wheel steering.MecalacThe appearance of the AS210 is unlike other Mecalac models, more angular and less flowing. “It was always intended to be a machine for heavier-duty applications, and it looks the part,” says Peter Bigwood, general manager, Mecalac North America.

As with other Mecalac swing loaders, the AS210 provides 90 degrees of loader swing left and right, has a non-articulated frame, and three-mode, four-wheel steering.

“The AS210 brings extra capacity to applications where the swing design is especially helpful such as backfilling and road jobs where it reduces the need for lane closures,” Bigwood says.

Deere’s three tiers

Deere is introducing its performance tiering strategy with wheel loaders. The G, P and X tier progress from basic, economical machines through machines with improved performance and comfort to machines with the latest features and technology Deere offers.

The 644 is the first John Deere wheel loader to be available in G, P and X tiers. The 644 X and P machines are now available for purchase in the U.S. and Canada; the 644 G machine is available in Canada and other global markets. Bucket capacities for the P and X tier machines are 4 to 4.75 cubic yards. (4.25 cubic yards G tier). Net power is 249 horsepower for the P and 231 for the X (227 horsepower for G tier).John DeereAs with its predecessors the 644K and 644L, the current 644 is an E-Drive hybrid with an engine-driven generator, an inverter, an electric motor and a PowerShift transmission specially optimized for use with the hybrid design. The 944K is also an E-Drive machine but uses four electric wheel motors.

Current Deere models 444 through 744 will be available in G, P and X tiers. “Those are recent models with no need for extensive modification to fit into Deere’s new tier structure,” says Luke Gribble, solutions marketing manager, Deere.

Komatsu’s transmission advancements

“Most wheel loaders are used as loaders and are designed to feed a process,” says Nathan Repp, product marketing manager of Komatsu’s WA200-8 through WA320-8. “However, all Komatsu loaders have optional auxiliary hydraulics for use with attachments and specialty buckets.”

The Komatsu WA475-10 has 22% more horsepower than the WA470-8 yet achieves up to 30% better fuel efficiency, thanks to the Komatsu Hydraulic Mechanical Transmission. KHMT also offers dynamic braking to reduce brake wear. Boom lift force is increased by 20% and breakout force by 8%. The new bucket design improves pile penetration and material retention.KomatsuAdam Brown, product marketing manager for Komatsu models WA320-8 through WA500-8, says the WA475-10 is the first of a new design and features the Komatsu Hydraulic Mechanical Transmission. The KHMT is a planetary gear design and provides stepless shifting. A dial sets a maximum travel speed while allowing full stroke of the accelerator for more precise control.

Other improvements include better ergonomics for the controls and switches, more glass area in the cab, and placement of the mirrors and rearview camera monitor at eye level.

Hyundai’s All-Around View

Hyundai HL900 series loaders have standard bucket capacities of 3 to 7.1 cubic yards. All models are available with standard or extended reach (XT) Z-bar linkage configuration. The HL940TM and HL955TM Tool Master models use a parallel linkage for greater lift capacity, improved load stability, rapid dumping capability and enhanced visibility.HyundaiHyundai Construction Equipment Americas’ A Series loaders feature enhanced onboard weighing that displays what’s in the bucket plus what’s in the truck. Names and target loads can be assigned to individual trucks.

An optional second monitor can be dedicated to the 360-degree, four-camera All-Around View Monitoring (AAVM) feature. The rearview system includes object detection. An optional radar further enhances safety.

Liebherr camera technology

The L580 features Liebherr’s XPower continuous power split driveline. XPower is fully automatic and has no traction interruptions across the entire speed range (up to 24.9 mph forward and reverse). Power is from an inline 6-cylinder engine rated at 312 horsepower. Bucket capacity is 7.5 cubic yards, and operating weight is up to 63,490 pounds.LiebherrOptional Active Personnel Detection is now available on Liebherr wheel loaders to monitor the area behind the loader.

Brake assistant uses camera technology and distinguishes between people and inanimate objects. Warnings can be evaluated using LiDAT, Liebherr’s telematics system.

Optional joystick steering is available, and customers can opt for joystick steering only, with no steering wheel or column.

LiuGong’s gradual rollout

“Demand for new applications started coming in late 2018,” says Hugo Chang, wheel loader product manager, LiuGong North America.

All LiuGong wheel loaders have third-spool hydraulics. Smaller models are plumbed to the end of the loader arms because they use quick connects, which require hydraulics.

The LiuGong 848H is powered by a Cummins QSB6.7 engine rated at 175 horsepower and has a ZF powershift transmission. Operating weight is 35,260 pounds, and bucket capacity is 3.5 cubic yards. Switching attachments is easy with the quick coupler, and the Z-bar linkage yields high breakout forces and stable material transport with minimal spillage.LiuGongLarger machines, which use pin-on buckets, are plumbed to a midpoint on the arms. Pilot controls are used for lift and tilt while an electrohydraulic thumbwheel controls the third valve. The company’s two largest models, the 877H and 890H, are fully electrohydraulic.

Chang says new model introductions usually coincide with emerging emissions regulations. Their current Tier 4 Final models came to market in 2016 and are being replaced with European Stage V machines. Because there is no U.S. equivalent to Stage V – that is, no Tier 5 – there is no deadline for introduction and therefore no urgency to bring these models to market.

“This gradual rollout allows us to implement the change to best benefit LiuGong, our dealers and our customers,” says Chang. “All our North America wheel loaders will likely be Stage V machines by 2023.”

Volvo boom kickout, return-to-dig

Boom kickout and return-to-dig are key features on Volvo loaders. Boom kickout height is set by the operator and is operated with a single stroke of the lever.

Volvo Construction Equipment is making its Load Assist machine control compatible with wheel loaders from the L60H to the L350H, including the L220H shown. Load Assist apps are operated via the Volvo Co-Pilot through the in-cab, 10-inch, high-resolution monitor. Calculator, Notes and Weather are called Toolbox Applications; tire pressure monitoring is also included. The Map app gives machine position and inter-machine telecommunication to provide real-time site activity.Volvo CE“It’s especially helpful when loading trucks at the same height for extended periods of time,” says Eric Yeomans, product manager for wheel loaders, Volvo CE North America.

Return-to-dig puts the bucket at the same position, again with a single lever stroke. Control sensitivity can be set to Soft, Normal or Active.

Lockup characteristics of Volvo models L110H through L260H can be set by the operator using OptiShift. The new lockup torque converter coupled with Volvo’s Reverse By Braking feature provides smoother directional changes, less driveline strain and greater fuel efficiency.

Wacker Neuson eases attachment switches

The largest Wacker Neuson articulated loader, the WL95, has a 2-cubic-yard bucket, 136-horsepower engine and Ecospeed PRO continuously variable hydrostatic transmission providing travel speeds of up to 24.8 mph. Flow to attachments can be easily adjusted using a jog dial. The articulation joint and pendulum rear axle provide a 96.5-inch inside turning radius with optimal traction.Wacker NeusonWacker Neuson puts a universal skid-style plate on smaller loaders, allowing attachments to be changed from the operator’s seat.

As the name suggests, this mounting plate is compatible with a range of attachments and work tools used with skid steer and compact track loaders.

Electrical and hydraulic connectors are standardized across Wacker Neuson models to further enhance compatibility.

Hitachi offers control options

Michael Winfield, product and applications manager, Hitachi Construction Machinery America (HCMA), says control configuration options vary by model. They can include three-spool control valve with multifunction and auxiliary levers; three-spool with two levers; four-spool with multifunction and auxiliary joystick; and four-spool with two levers and two auxiliary levers.

Key features on the Hitachi ZW220-6 include lift arm auto lever that allows the operator to set boom kickout via the multifunction screen, joystick steering, parallel/tandem hydraulics for more efficient lifting and dumping and a shift-to-hold switch that overrides automatic settings and allows the operator to hold the transmission in its current gear.HitachiApproach Speed Control automatically increases lift-arm speed while maintaining drive speed, and Intuitive Rim Pull Control provides additional power as required to boost breakout force in digging applications. Torque proportioned differentials minimize wheel slippage.

HCMA features also include ground-level-accessible grease points and an automatic reversible cooling fan and wide-fin cooling core.

Yanmar adds comfort

The V12 is Yanmar’s biggest wheel loader. Bucket capacity if from 1.57 to 2.35 cubic yards. Operating weight of this 100-horsepower loader is 15,432 pounds. A quick coupler is standard as is joystick control with third and fourth control circuit in one hand. Both axles have automatic-locking differentials. Hydrostatic drive provides infinitely variable speed control forward and reverse as well as an inching pedal.YanmarYanmar has one model in this size class, the V12. Its rubber-mounted cab includes HVAC, extra high-back suspension seating with lumbar support and two doors for easy access.

The joystick provides third- and fourth-spool controls. A central lubrication system is available.

Takeuchi focuses on owner-operators

Takeuchi also has one model in this range, the TW95. Features include a cab with air-ride suspension seating, two-speed travel and an inching pedal.

Top travel speed is nearly 25 mph; the inching pedal maintains engine speed while metering travel speed.

The Takeuchi TW95 is powered by a Deutz TCD 3.6 liter inline 4-cylinder engine rated at 114 horsepower. Differentials are 100% locking; 12 degrees of center pin oscillation allows equipment movement while keeping the operator’s station stable. Hydrostatic drive provides up to 24.8 mph travel speed and dynamic braking, slowing the loader as the operator backs off the throttle. Linkage is Z-bar for greater breakout and loader arm forces.TakeuchiStandard automation features include boom height kickout, return-to-dig and automatic bucket positioning.

“We make all our wheel loaders comfortable and easy to operate since many are purchased by owner-operators,” says Lee Padgett, product manager.

Did you miss our previous article…

https://constructionosa.org/?p=237

Best Recruitment Strategies For Construction Companies

Therefore, we have come up with this guide of the best recruitment strategies for construction companies. Construction recruitment process.

The post Best Recruitment Strategies For Construction Companies appeared first on ConstructionPlacements.

Did you miss our previous article…

https://constructionosa.org/?p=208

Cat 777G Water Solutions Truck Varies Water Output to Meet Site Conditions

As we enter the driest part of the year for many regions of the country, Caterpillar has come to the rescue of dusty worksites with a its new 777G Water Solutions truck platform.

The redesigned Cat 777G doesn’t just throw water out haphazardly, it uses a Water Delivery System (WDS) combined with Cat MineStar Edge connectivity to vary the water flow by truck speed. This conserves water and prevents overwatering and all the problems that result from turning a dusty site into a muddy one including traction and visibility issues. It also conserves water, which reduces the number of fill-ups and helps in drought prone areas.

A variable displacement pump automatically starts and stops when the truck slows or comes to a halt. Soft start-ups also eliminate excess watering, and the pump turns off automatically when the tank is empty, preventing damage to the system from the pump running dry.

The WDS components include a water cannon, oil cooler, variable displacement pump, hydraulic oil tank, electronic control boxes and a hydraulic motor and water pump. In the adaptive economy mode, the truck’s engine uses up to 13 percent less fuel than full power mode. And the water cannon operates at engine idle speed, further reducing fuel consumption by up to 50%.

Standard equipment on the new Cat 777G Water Solutions truck includes an integrated 20,000-gallon Cat-branded water tank, complete with spray system, splash guards, fill chute and rock ejectors. Remote tank fill control, complete with auto shut-off to prevent overfilling, enables the operator to remain inside the cab during refilling to reduce potential operator slips and falls. Retrofit kits are available for existing Cat 777G truck platforms in the field.

Did you miss our previous article…

https://constructionosa.org/?p=207

Toyota to Produce Class 8 Fuel Cells in Kentucky Plant

After thousands of miles of real-world testing in commercial trucking, Toyota announced today that it’s preparing to take its hydrogen-powered fuel cell electric technology from prototypes to production in its efforts toward carbon neutrality.

Starting in 2023, a dedicated line at Toyota Motor Manufacturing Kentucky (TMMK) will begin assembling integrated dual fuel cell modules destined for use in hydrogen-powered, heavy-duty commercial trucks. Fuel cell modules bring Toyota’s electrification strategy further into focus as it will allow truck manufacturers to incorporate emissions-free fuel cell electric technology into existing platforms with the technical support of Toyota under the hood.

“We’re bringing our proven electric technology to a whole new class of production vehicles,” said Tetsuo Ogawa, president and chief executive officer, Toyota Motor North America. “Heavy-duty truck manufacturers will be able to buy a fully integrated and validated fuel cell electric drive system, allowing them to offer their customers an emissions-free option in the Class 8 heavy-duty segment.”

The dual fuel cell modules, which are a key component of an overall fuel cell kit, weigh approximately 1,400 pounds and can deliver up to 160kW of continuous power. The fuel cell kit also includes a high voltage battery, electric motors, transmission and hydrogen storage assembly from top-tier suppliers. Toyota will also offer its powertrain integration knowledge to help truck manufacturers adapt these emissions-free drivetrain systems to a wide variety of heavy-duty truck applications.

“This second-generation fuel cell system is necessary for a carbon neutral future,” says David Rosier, Toyota Kentucky powertrain head. “It delivers over 300 miles of range at a full load weight of 80,000 pounds, all while demonstrating exceptional drivability, quiet operation and zero harmful emissions.”

Toyota displayed this technology at the 2021 Advanced Clean Transportation (ACT) Expo in Long Beach, California held last week.. A prototype truck powered by Toyota’s fuel cell kit was also on display.

Did you miss our previous article…

https://constructionosa.org/?p=206

HURL Recruitment 2021 for Executives | 44 Posts | 15-09-2021

HURL Recruitment 2021 for Executives on a contract basis with 44 Posts vacancies, last date to apply is 15-09-2021

The post HURL Recruitment 2021 for Executives | 44 Posts | 15-09-2021 appeared first on ConstructionPlacements.

Did you miss our previous article…

https://constructionosa.org/?p=205

Hilti Launches Cut Assist Semi-Autonomous Drilling System

One of the toughest jobs in construction is drilling a clean, accurately dimensioned hole in a concrete structure.

Hilti’s solution is to pair its DD 250-CA diamond core drill with a DD AF- CA Cut Assist auto-feed unit that intuitively guides the tool through the entire drilling process. The company calls this a semi-autonomous drilling system and says contractors using it can achieve significant productivity gains and convenience on jobsites.

The DD 250-CA diamond core drill uses integrated technology to provide the operator guidance for proper drill setup, real-time drilling feedback, and productivity data once the drilling is complete. The smart tool is designed for a full range of applications including drilling penetrations for ducts, pipes and cables and drilling blind holes for setting anchors or post-installed rebar. For Hilti customers who have the DD 150 U diamond core drill, the DD AF-CA L auto-feed unit can be used.

With Hilti Cut Assist technology, operators can perform difficult coring jobs with greater safety, more comfort and less fatigue in difficult conditions. Intelligent features include automatic surface detection, tracking of drilling depth, water management, hole starting and through-hole detection.

To reduce concrete dust and stay on the right side of OSHA silica regulations, the Hilti WMS 100 BLE water-management system and auto-feed units automatically work together to provide a complete system solution.

Did you miss our previous article…

https://constructionosa.org/?p=204

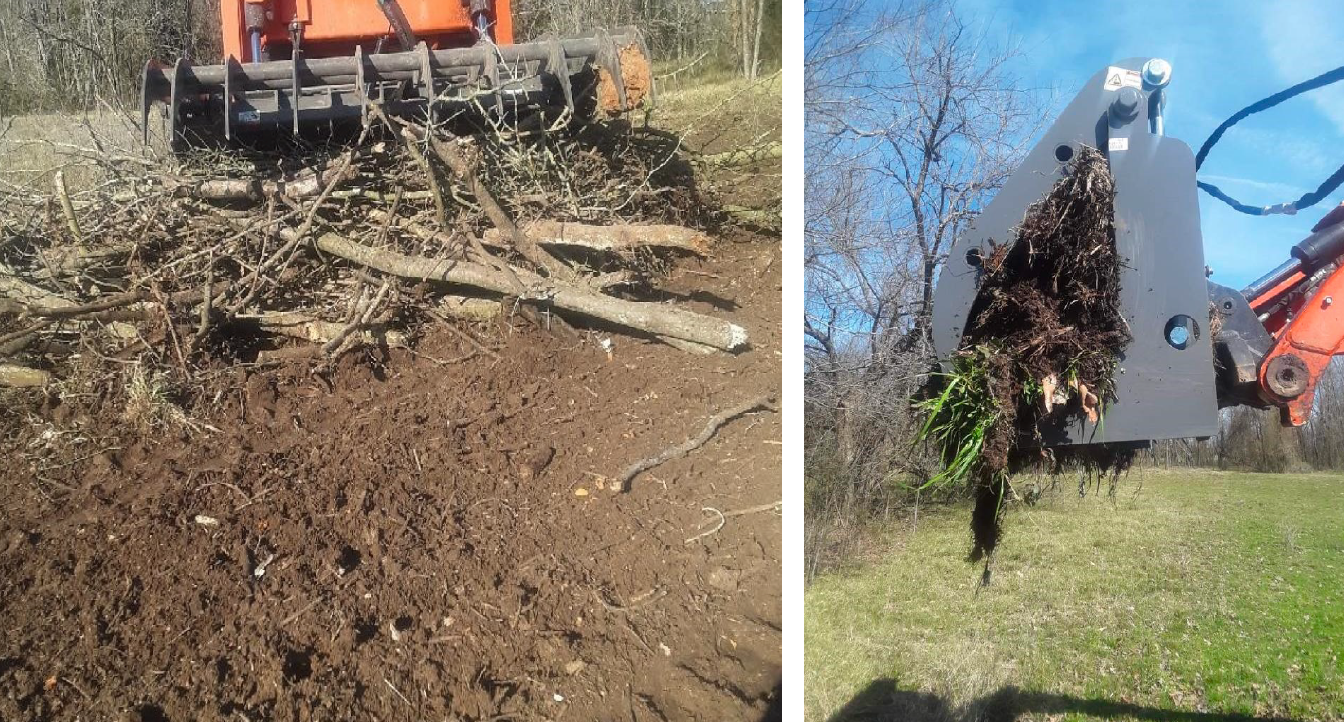

Slash, Rip, Rake and Grab with These 13 Attachments for Clearing Land

When it comes time to slash and grab, check out these 13 construction equipment attachments for clearing land.

Our product roundup includes a variety of brush and forestry cutters for chopping through thick vegetation and small trees with your construction equipment.

Then when it’s time to clean out the felled debris, several types of rakes and grapples for excavators, compact equipment and dozers can help you tackle the job.

Mowing and Mulching

John Deere’s RX72 and RX84 rotary cutters are designed for heavy-duty vegetation management, including property maintenance and right-of-way clearing. They are compatible with large-frame Deere skid steer and compact track loaders. Each model uses a skid steer coupler interface to mount to the carrier. They are equipped with high-flow hydraulics and a severe-duty door. The motors have a direct drive bearing for higher efficiency and extended durability. The blade carrier is designed for faster startup and recovery time.

The Bobcat BrushcatBobcatThe Brushcat rotary cutter from Bobcat can mulch branches and saplings up to 3 inches in diameter, as well as cut through thick grass and brush. It is designed to follow the contours of the ground for a clean, even cut, including on slopes. High-flow models are available for brush-cutting jobs that require extra torque, such as clearing construction sites and controlling brush and undergrowth. The cutter operates while moving forward or in reverse. Features include an offset dual motor and blade and a short deck for visibility and tight turning.

Case mulching headCase CECase’s mulching head for the company’s skid steers and compact track loaders features a two-speed motor that automatically adjusts motor displacement to maximize rotor speed and torque to the material load. The mulcher comes standard in a high-flow configuration but can be converted at dealerships to “enhanced high flow” for machines of 90 horsepower and up. It comes standard with double-carbide teeth. A Samurai knife tool for finer chip sizes is optional. A deflector is also an available option for containing and fine-cutting debris.

Eterra Typhoon Clearing MowerEterraThe Eterra Typhoon Clearing Mower for skid steers and compact track loaders is designed to be an industrial grade cutter for a lower price. It features a large, heavy drive system to achieve professional grade performance. The blade bar is a double-reverse diamond shape for easy startup and to deliver a powerful spinning action while maintaining moderate mulching ability. The blade holder is made of 1-inch-thick T1 structural steel that has been laser cut and computer numerical control machined.

JCB forestry cutting headJCBJCB’s forestry cutting head can cut down trees up to 8 inches in diameter, as well as shred and mulch them. Operators of skid steers and compact track loaders can control material discharge speed and material size from the cab with the hydraulic, adjustable deflector door. An in-line hydraulic oil cooler reduces heat in the hydraulic system. Available in a 60-inch-wide cutting width, the cutting head runs on a high-output variable-displacement piston motor with a self-aligning belt. A heavy-duty adjustable push bar helps topple trees and protects the carrier machine.

Ammbusher AC AC720 Brush CutterPremier AttachmentsPremier Attachment’s Ammbusher AC720 Brush Cutter is made for high-flow skid steers clearing medium to heavy brush and hardwoods up to 8 inches in diameter. It can handle road right-of-way, pipeline maintenance, forestry and land management operations. The 2,400-pound AC720 can cut, mulch, shred and grind brush and trees. Features include a hydraulic pressure gauge for the operator to monitor the cutting load, four ¾-inch-thick blades, and spindle interrupters to prevent wire, twine and vegetation from wrapping around the drive shaft.

Takeuchi Fixed-Tooth Forestry MulcherTakeuchiTakeuchi’s Fixed-Tooth Forestry Mulcher is available for compact track loaders with flow rates of 16 to 55 gallons per minute. It comes in widths of 69 to 83 inches. It can also be equipped with Takeuchi IQ, an intelligent speed-management system that helps maintain rotor speed and prevents stalling. It also allows operators to calibrate the mulcher to the CTL with the touch of a button; no tools are required. A protruding rotor lets the mulcher process more material without dragging it. An enclosed-door drive prevents dirt from entering the machine’s service area.

Woods Equipment TurfKeeper Pro MowerWoods EquipmentThe TurfKeeper Pro is Woods Equipment’s premium-duty rear-mount finish mower for tractors of 15 to 50 PTO horsepower. It comes ready for quick hitch and has an improved driveline holder for ease of attachment. It also features new high-lift blades, under-deck baffling and a wider discharge outlet. It is available in cutting widths of 60, 72 or 84 inches. Other new features include belt shields that attach by thumbscrew with no tools required and ductile iron sheaves for better belt grip. It has a gearbox warranty of six years.

Raking and Grabbing

Berlon Root Rake GrappleBerlonThe Berlon Root Rake Grapple is designed for mini skid steers, also known as compact utility loaders, and compact tractors. It can be used to clean up brush and debris, pull out vines and remove the upper root layer to prepare the ground for seed or sod. It is designed to be lightweight and durable. Its reinforced 3/8-inch tines are spaced 8 inches apart. The end tines are serrated for grabbing small logs. The grapple opens 50 inches wide for handling large loads. Cylinders are protected and hoses are enclosed to reduce maintenance.

Danuser Multi-Purpose GrappleDanuserDanuser’s Multi-Purpose Grapple expands the use of pallet forks for carrying such items as logs, rocks, brush and debris. It can be pinned in an upright position, allowing for normal pallet fork use without having to remove the grapple from the frame. No tools are required for this. Other features include a heavy-duty rail-style frame that supports up to 6,000 pounds, 48-inch-long tines with 3,500- or 5,500-pound capacity and skid steer and front-end loader mounting options. It delivers up to 9,500 pounds of force at 3,000 psi.

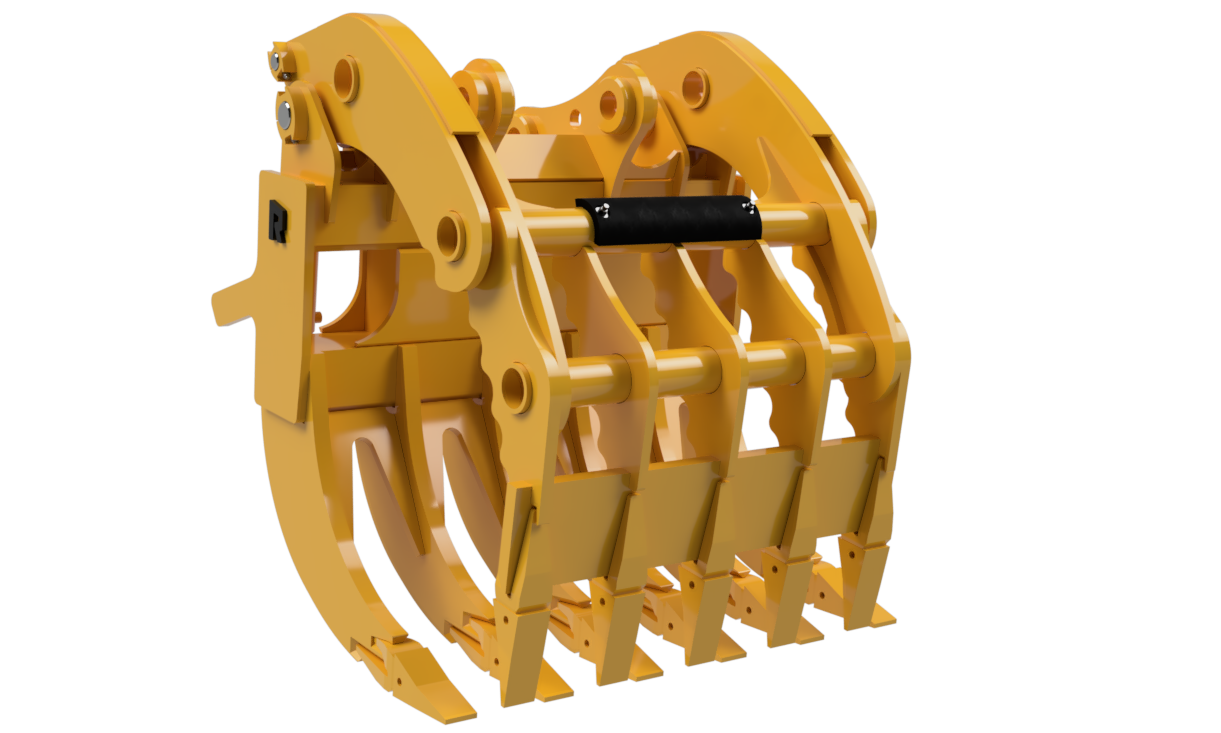

Rockland Krypto Klaw Grapple RakeRockland ManufacturingRockland’s new Krypto Klaw Grapple Rake for excavators allows operators to grab large, bulky materials and debris. Its dual-cylinder clamp delivers more force in all positions than a bucket thumb, as well as better control, the company says. It uses 100% of the excavator’s reach. It attaches to the excavator stick with a pin or excavator coupler; no welding is required. The standard design has a cutting edge. It can also be configured with pin-on, replaceable teeth. It comes with a two-year, 4,000-hour warranty.

Werk-Brau Hydra-clampWerk-BrauThe Werk-Brau Hydra-clamp bucket for excavators is designed for handling heavy, awkward or bulky items that can be encountered when moving debris. It delivers a clamping force of up to 54,000 foot-pounds of torque at 3,000 psi. That force is delivered consistently throughout the attachment’s 120-degree range of motion. There are no exposed cylinders. Serrated side plates help secure debris when moving and are available in a variety of sizes. The bucket is constructed of wear-resistant, high-strength steel in critical areas. It is also available as a rake.

Bedrock Attachments’ ripper for Cat dozersBedrock AttachmentsBedrock Attachments2BBL Multi-Shank Ripper fits Cat D7R and D7H dozers. The parallelogram style ripper has two lift cylinders. It can accept OEM style parts, including cylinder and seal kit. The ripper ships assembled and includes mounting bolts, three ripper tines with three tips, transmission guard and cylinder hoses. It is 7.9 feet long, 7.2 feet wide, 4.4 feet tall and weighs 3.8 tons.

Did you miss our previous article…

https://constructionosa.org/?p=190

Structural Engineer Job Description and Salary Details

What does a structural engineer do? Learn about Structural Engineer Job Description, roles & responsibilities, and Salary Details.

The post Structural Engineer Job Description and Salary Details appeared first on ConstructionPlacements.

Did you miss our previous article…

https://constructionosa.org/?p=189