Home » Articles posted by Tessa Sanderson (Page 23)

Author Archives: Tessa Sanderson

Industry News Roundup: H&E Opens Kansas City Branch

H&E Equipment Services is expanding into the Midwest with the opening of its new Kansas City branch. The 21,000-square-foot facility sits on nearly 2 acres with six service bays, a fenced-in yard, offices and parts warehouse.

The branch specializes in the rental of aerial lifts, telescopic forklifts, earthmoving machinery, compaction equipment, generators, compressors, and more and represents the following manufacturers: Allmand, Atlas Copco, Blue Diamond, Bomag, Case, Club Car, Gehl, Generac Mobile, Genie, Hamm, Husqvarna, JCB, JLG, John Deere, Kubota, LayMor, Ledwell, Link-Belt Excavators, MEC, Miller, Multiquip, Okada, Polaris, Skyjack, SkyTrak, Sullair, Sullivan-Palatek, Takeuchi, Towmaster Trailers, Wacker Neuson, Wirtgen, Yanmar, and others.

Case CE names Diamond, Gold dealers

Case Construction Equipment has named its top 2020 dealers, recognized for excellence in sales performance, marketing and communications, product support, parts support and training.

The 2020 Diamond Dealer award winners are: ASCO Equipment (Texas), Groff Tractor (Pennsylvania, Maryland and New Jersey), J.R. Brisson Equipment (Ontario, Quebec), Longus Equipment (Quebec), McCann Industries (Illinois, Indiana and Michigan) and Redhead Equipment (Saskatchewan).

The 2020 Gold Dealer award winners are: Crawler Supply (Louisiana), Eagle Power & Equipment (Delaware, Pennsylvania), HiTrac (1974) Inc. (Winnipeg, Manitoba), Kucera Group (Ontario), Lawrence Equipment (Virginia, North Carolina), Medico Industries (Pennsylvania), and Monroe Tractor (New York, Massachusetts and Connecticut).

General Equipment adds Superior Industries coverage

General Equipment & Supplies, Fargo, North Dakota, will add Minnesota and North Dakota to its coverage of Superior Industries’ full line of equipment.

General will offer Superior’s crushing, screening, washing and conveying equipment in addition to parts and service. The dealership first offered Superior products in 1982 and has 10 branches throughout four Midwestern states.

MANUFACTURERS, SUPPLIERS

CNH Industrial Q2 revenues at $8.9 billion

CNH Industrial reports revenues for the second quarter were up 60% year over year.

The Case Construction Equipment parent says its construction order book was up YOY in both heavy (up 6%) and light (up 21%) subsegments. Construction equipment demand increased 42% in North America and net sales were up 92% globally.

Hyundai deal With Doosan Infracore in final stages

The expected Hyundai Heavy Industry Holdings $735 million buy of Doosan Infracore from Doosan Heavy Industries & Construction has moved through a major regulatory hoop, having gotten the OK from the Korea Fair Trade Commission, according to a report by The Korea Herald.

Newly formed HHIH affiliate, Hyundai Genuine, will have a 35% stake in Doosan Infracore, says the paper.

As reported earlier, Doosan Bobcat is not part of the deal and remains with Doosan Heavy.

When the deal was announced in December, Doosan Infracore North America told Equipment World in a statement that the deal didn’t mean that North American customers will see a combined Hyundai/Doosan market presence.

Terex raises 2021 guidance after strong Q2

Terex has raised its full-year sales outlook to $3.9 billion following Q2 net sales of $1.03 billion, compared with $690 million in Q2 2020.

The company’s aerial work platform division had Q2 net sales of $595 million, compared with $413.9 million last year during the same time period. Terex’s material processing division net sales rose from $263 million in Q2 2020 to $440 million in Q2 2021.

Did you miss our previous article…

https://constructionosa.org/?p=84

HDD Bonanza? Fire Hazards Prompt PG&E to Go Underground

After saying for several years that underground the installation of high-voltage, long distance electrical transmission lines was too expensive, Pacific Gas & Electric has changed course.

On July 22, the utility giant announced plans to bury as much as 10,000 miles of its electrical transmission lines underground in fire-prone areas of California. Cost is estimated to be $20 billion over the course of a decade or more. The move was prompted by the catastrophic damages, lawsuits and bankruptcy PG&E suffered after wildfires caused by sparking electrical lines swept through Northern California in 2017 and 2018.

The move is not only good news for contractors and residents of California but highlights an apparent change in thinking about the need to harden critical infrastructure. The timing of the announcement came just a week before the U.S. Senate agreed to authorize a massive $1-trillion-dollar infrastructure bill, of which $73 billion is earmarked to modernize the nation’s electrical grid and $50 billion is allocated to protecting infrastructure against climate change and cyber-attacks.

“Our goal is 10,000 additional miles of overhead lines converted to underground,” says PG&E spokesperson Paul Doherty. “We’re starting now and we won’t stop until we’ve finished.” The state currently maintains approximately 25,000 miles of overhead transmission lines.

The exact number of projects or miles of transmission line put underground each year will evolve as the utility develops project scopes, estimating and engineering review, says Doherty. The utility also said it will partner with natural gas providers and telephone and internet companies to develop joint trenching projects and share costs.

Major underground utility infrastructure upgrades are happening all around the country, but the PG&E project may be one of the largest of its kind, says Jerry Beyer, director of sales – Infrastructure Group at Vermeer.

“It’s not uncommon for us to see massive rollouts of projects when it comes to fiber installations,” says Cory Maker, horizontal directional drilling product manager at Ditch Witch. “For an individual project, this is a pretty large given what they want to do and period of time they want to get it all done.”

Pilot projects

PG&E initiated a handful of pilot projects to test the feasibility of putting high-voltage power lines and gas infrastructure underground in 2018. Proof-of-concept projects were completed in the high fire threat areas of Alameda, Contra Costa, Nevada and Sonoma counties.

Near Oakland the utility put approximately 3,500 feet of 12-kilovolt distribution line and reinforced the secondary conductor in trenches cut 36- to 42-inches deep and vaults dug to 7-feet 6-inches deep. PG&E also converted an overhead transformer to a pad mount. “The goal of these projects was to help evaluate placing overhead conductor underground as a wildfire safety measure, and to better understand the costs and construction requirements associated with undergrounding for system hardening purposes,” says Doherty.

“There will be an initial ramp-up period due to limitations in our supply chain and labor force,” says Doherty. “But within a couple of years, we will be doing ten times the mileage we are doing today. Eventually we will be completing well over 1,000 miles per year. By comparison, this year we are undergrounding about 70 miles,” he says.

Ramping up

PG&E’s 10,000-mile project aside, HDD and underground infrastructure contractors are in high demand all over the country. “The fiber market is growing tremendously, and there are a number of large electrical projects currently happening with many more projects kicking off in the near future,” says Beyer.

This is especially true of electrical utilities on the East Coast from Florida to Washington DC. Multiple regional utilities are taking overhead power lines and burying them underground to better survive hurricanes, ice storms and other destructive weather events.

Maintenance costs driving change

The historical argument against underground electrical utilities has been that they are more expensive to install, but the thinking on that is starting to change, says Beyer. Installation costs are only one part of the equation.

According to a study published by the utility consulting company PDI-Squared, the maintenance of underground electrical utilities can be three to seven times less expensive than maintenance of overhead utilities. No doubt the increase in catastrophic fires and weather events on both coasts as well and the 2021 winter storm damage to electrical utilities in Texas, Arkansas and Louisiana, have forced utilities nationwide to reconsider their long-term interests when it comes to installation vs. maintenance costs.

Busy industry about to get busier

PG&E’s announcement comes at a time when underground contractors are plenty busy with just the normal sewer and gas pipeline work, says Maker. But the industry is ready to meet the challenge, he says.

“You may see subsidiaries from all over the United States and even some global contractors traveling to California to work on the PG&E project,” says Maker. “It is not uncommon for HDD contractors to travel substantial distances for work especially when they specialize in certain types of jobs.”

Tough terrain

HDD rigs in the 40,000-pound class and under, such as this Ditch Witch AT40, will play a role when the soil conditions and bore design don’t present bigger challenges.Ditch Witch

The areas where much of this work will take place have some of the most rugged, mountainous and challenging terrain in the country, and that’s the kind of environment where HDD can really shine, says Maker. Rock saws, trenchers and open cut methods will also be used where they make sense. But HDD work is less invasive than open cut trenching. In HDD operations contractors don’t have to maneuver and stage large fleets of equipment in the mountains and around obstacles in the terrain.

The size of HDD drills used in the PG&E project will vary on the length of the bore and the terrain and soil conditions. Maker says a lot of underground electrical work done with rigs in the 40,000 pound and under class, where in good soil conditions it is possible to complete 3,000 to 5,000 feet a day. But in densely forested areas you’ll see longer bores and bigger rigs used to avoid multiple set ups and disturbing the forest, he says.

”Soil conditions also have an impact on equipment decisions,”, says Beyer. “When working in rock, many contractors will use larger drill rigs and/or trenchers paired with tooling designed for those specific conditions to achieve optimal efficiency. In ground where there may be a mixture of clays, fragmented rock or boulders, a different machine and tooling combination may deliver better productivity.”

Andy Bremner, external sales manager-pipeline for Vermeer, says the hard rock formations common in Northern California may require larger rigs: 100,000 to 200,000-pound class machines depending on the bundle diameter and in some circumstances even up to the half-million-pound size class depending on the length of bore and how it is designed.

Water management essential

In water-parched California, water reclamation will also play a major role in undergrounding PG&E’s electrical lines. HDD contractors often pair midsize and larger rigs with drilling fluid reclaiming equipment to help manage the total volume of water needed.

Reclaimers conserve water can also reduce the amount of bentonite and additives needed. Water conversation and project efficiency gains are also driving the use of reclaimers on smaller scale projects.

OEMs ready, labor shortages loom

Both Ditch Witch and Vermeer agree that the industry won’t have any problems ramping up the production of machines—HDD units as well as trenching machines and support equipment—for the increased amount of work coming into the underground industry.

“We are in constant communications with our dealer and customers, so we can stay in tune with the level and type of support they need today, and in the future,” says Beyer. “We are ready to support this project with equipment, tooling, parts, service and training.”

“The biggest problem the industry faces is the lack of skilled operators who can go out there and drill and locate,” says Maker. HDD work is significantly more complex than regular earthmoving and heavy/civil construction. Mistakes are expensive and can lay waste to a schedule.

Both manufacturers run their own education classes at various dealerships and both support trade school programs: Ditch Witch and Vermeer are support partners with State Technical College of Missouri, and Vermeer has worked several years with the Des Moines Area Community College. Interesting as well is that both companies use machine simulators to train prospective operators in trenchless techniques and technology.

“With the simulator, guys can learn a lot without having to sit on a rig costing several hundred thousand dollars,” says Maker. “That’s been very appealing to the younger generation as they come into the labor force,” he says.

Did you miss our previous article…

https://constructionosa.org/?p=81

Trail KIng Live-Bottom Trailer Designed for Maneuverability, Maintenance … and Good Looks

Trail King’s new live-bottom trailer is flashy on the outside, rugged on the inside with lots of features that make maintenance easier to boot.

Inside the eye-catching aluminum or stainless-steel trailer sides and front wall are hopper walls with long-lasting 4-millimeter thick AR450 wear plate in the rear half, with full length wear plates available as an option. A heavy-duty, 4-inch pitch roller chain and frictionless drive system make quick work of discharge, unloading the full trailer in one revolution or less.

Round cross members attach to cast steel mounts on the side walls to reduce material build up. The simplified rear tailgate offers corrosion-resistant aluminum lift cylinders and an auto flip-up option.

The air and electrical lines are mounted on the exterior with aluminum or stainless-steel covers for simplified maintenance. The exterior front bearing assembly is easy to get to, and the chain oiler and brushes are located at the front idler for better oil distribution and accessibility. Likewise, the bolt-on upper coupler/kingpin and front fenders make maintenance faster and easier.

The new Trail King live-bottom trailers are also offered in single or dual hydrostatic drive and multiple axle configurations.

Did you miss our previous article…

https://constructionosa.org/?p=56

Why is Construction Employment Still Lagging Pre-Covid Levels?

Construction employment in June remained below the pre-pandemic levels of February 2020 in 39 states, according to an analysis by the Associated General Contractors of America.

New York and Wyoming suffered the worst losses, while Utah and Idaho added the most construction jobs. New York, Vermont and Iowa had the biggest declines in June. Georgia and Kentucky were the top gainers.

AGC officials put the blame on supply chain shortages and rising material prices, which are undermining demand for new projects and impacting construction firms’ ability to hire workers.

“The construction industry is a long way from full recovery in most states, in spite of a hot homebuilding market in many areas,” said Ken Simonson, AGC chief economist. “Soaring materials costs, long production times for key items and delayed deliveries are causing owners to postpone projects.”

16 months into pandemic

From February 2020 to June 2021, New York shed the most construction jobs (54,300 jobs or 13.3%) followed by Texas (54,100 jobs, 6.9%) and California (36,500 jobs, 4%). Wyoming recorded the largest percentage loss (15.3%, 3,500 jobs), followed by Louisiana (15.1%, 20,700 jobs) and New York.

On the positive side, Utah added 7,000 jobs, (6.1%), followed by Idaho with 4,400 jobs (8%), South Dakota (1,400 jobs, 5.9%) and Rhode Island (1,200 jobs, 5.9%). Idaho claimed the largest percentage gain, followed by Utah, Rhode Island and South Dakota.

May to June 2021

From May to June of this year, construction employment decreased in 25 states, increased in 24 states and D.C., and held steady in Maine. The largest declines occurred in New York, which lost 6,900 construction jobs (1.9%), followed by Pennsylvania (4,100 jobs, 1.6%) and Texas (3,300 jobs, 1.3%). The steepest percentage declines since May occurred in Vermont (3.5%, 500 jobs), followed by New York, Alabama (1.9%, 1,700 jobs), and North Dakota (1.9%, 500 jobs).

Georgia added the most construction jobs between May and June (5,700 jobs, 2.9%), followed by Kentucky (2,700 jobs, 3.4%) and Florida (2,500 jobs, 0.4%). Kentucky had the largest percentage gain for the month, followed by Alaska (3.0%, 500 jobs) and Georgia.

Tariffs, logistics and unemployment

Association officials cautioned that construction employment is unlikely to grow in many parts of the country until supply chain challenges improve. They added that President Joe Biden could help by removing tariffs on key construction materials. The AGC also noted that ending the unemployment supplements would add to the pool of workers for manufacturers, shippers and construction firms to hire.

“Easing tariffs will help, but what the construction supply chain needs are workers to manufacture the products, ship them to contractors and build the projects the economy demands,” said Stephen E. Sandherr, the association’s chief executive officer. “Unemployment supplements helped families survive the pandemic-related lockdowns, but they are undermining the post-pandemic recovery.”

Did you miss our previous article…

https://constructionosa.org/?p=55

Add On When Needed: Panasonic 2-in-1 Toughbook G2 Built for the Future

Panasonic continues its year of Toughbook introductions, this time with an eye toward users who not only want the option of a keyboard but also future-proof technology.

A keyboard is only the first of the options on the G2 fully rugged 2-in-1 detachable tablet. There are several add-ons expansion packs or what Panasonic calls xPaks that give the unit functions such as a serial port, thermal camera, barcode reader and a quick-release SSD hard drive. Owners can add this functionality in three modular expansion areas whenever needed since the xPaks are user installed and removed.

The Panasonic Toughbook G2 can be operated solely in tablet form or be paired with a keyboard.Panasonic“No other table has this modular expansion pack approach,” Anthony Mungiello, Toughbook senior product manager, tells Equipment World. “You can get a total of 36 combinations between the three expansion areas. This gives people flexibility, helps future proof the G2, and they can add any of these xPaks at any time.” Contractors can also share xPaks among several users.

The G2’s 10.1-inch display is available with Windows 10 Pro; the unit has an 18.5-hour battery life. It also has three programmable buttons to quickly access commonly used applications or shortcuts. Working in landscape mode, one of the programmable buttons is located on the right-hand side of the tablet, making it easy to use as a camera or scanner.

“If you have a barcode scanner, for example, you can program one of your buttons to immediately go to the scanner,” Mungiello says.

And all of this comes with the baked-in ruggedness Panasonic has spent the past 25 years developing in its Toughbooks. In part because of this legacy, the company is making the G2 backward compatible with docking stations on the Toughbook 20, which came out in 2015, and the Toughbook G1, which came out in 2013.

“We know there are thousands of devices out there that are mounted in work vehicles, and being able to reuse those docking stations is a huge cost savings,” says Alex Nollmann, Panasonic’s director of public sector.

The G2’s heat management should be of particular interest to contractors, Nollmann says. “It can easily be in direct sunlight on a hot day. The device handles extreme heat.” Panasonic’s use of thermal piping keeps the processor from overheating and does not impact the integrity of the unit, he says.

Contractors might also be attracted to the G2’s screen brightness – or lack thereof. “We’ve been known for years for having extremely bright screens, but it’s also becoming more important to have dim screens as crews work at night,” Nollmann says. “You don’t want a 1,000-nit screen affecting their night vision on the side of the road.”

The G2 can go down to 2 nits, which almost appears as a black screen except in a complete blackout environment. More important, it has a night vision mode that turns the screen a red hue, taking out the whites and blues, enabling users to look at the screen and then at the surrounding environment without losing night vision. Users can activate this feature manually or have it come on automatically as it senses ambient light.

Nollmann also says the G2’s speakers are four times louder than previous models, making it easier to hear on noisy construction sites.

With the 2-in-1 design, the G2 can be used as a tablet or laptop. It uses Wi-Fi 6 and Bluetooth 5.1 and has 16 GB to 32 GB of memory. The 2.9-pound basic tablet starts at $2,999, with xPaks and keyboard sold separately. The keyboard adds another 2 pounds.

“Dual SIM (physical and eSIM) is actually innovative in the rugged space,” Mungiello says. Using eSIM, users can easily install SIMs on multiple units, and they don’t have to worry about the SIM card coming loose in a vibration-intense environment.

Did you miss our previous article…

https://constructionosa.org/?p=52

Industry News Roundup: EquipmentShare Gains $230 Million in Funding

EquipmentShare says its new $230 million funding will help it launch its core T3 construction operating system and expand its suite of technology solutions.

“We are eager to leverage this milestone round to launch several initiatives, with the continued goal of empowering contractors and accelerating productivity in construction,” says Willy Schlacks, EquipmentShare president and co-founder.

The company says it will soon launch T3, a solution that digitizes and connects assets, people and materials. T3 will “give contractors real-time visibility into parts of the jobsite that are historically difficult to track and manage,” it says.

In addition, Columbia, Missouri-based EquipmentShare says it plans to significantly increase its footprint in the U.S. in 2021 and grow its total presence to more than 100 locations, including rental, retail and service. It now says it’s hiring 100 new employees a month.

The funding round was led by Tiger Global Management, The Spruce House Partnership and RedBird Capital Partners. Addition participation came from Tru Arrow Partners and EquipmentShare’s existing investorsRomulus, Insight Partners and Anchorage Capital Group.

tlas Copco adds Caisson Consultant

Atlas Copco

Caisson Consultant has been named a dealer for Atlas Copco Power Technique.

Caisson will provide sales, service warranty and application knowledge for Atlas Copco’s DrillAir high-pressure air compressors.

Incorporated in 2004, Caisson provides foundation equipment in the Ontario, Canada region, focusing on foundation drilling and geotechnical market segments. Specializing in piling, anchor, tieback and limited access machines, it offers technical support, rentals, sales, RPOs, tooling and wear parts.

Trophy Tractor builds Burleson facility

Trophy Tractor is adding a 28,000-square-foot facility on 13 acres in Burleson, Texas. The new facility will have eight service bays in a climate-controlled shop area, a 5,000-square-foot office space and a parts storage building.

The company specializes in providing new, used and reconditioned haul trucks, loaders, dozers, scrapers, excavators, along with a variety of other earthmoving equipment.

MANUFACTURERS, SUPPLIERS

Hitachi hires customer care director

Hitachi Construction Machinery Loaders America has hired Marcelo Fazolin as its director of customer care.

In his new position, Fazolin will spearhead Hitachi’s After Sales Solution mission, which includes parts, support services, ConSite fleet management solution, global e-Service platform, remanufacturing and training.

Fazolin comes to Hitachi after global experience in automotive sales channels and supply chains.

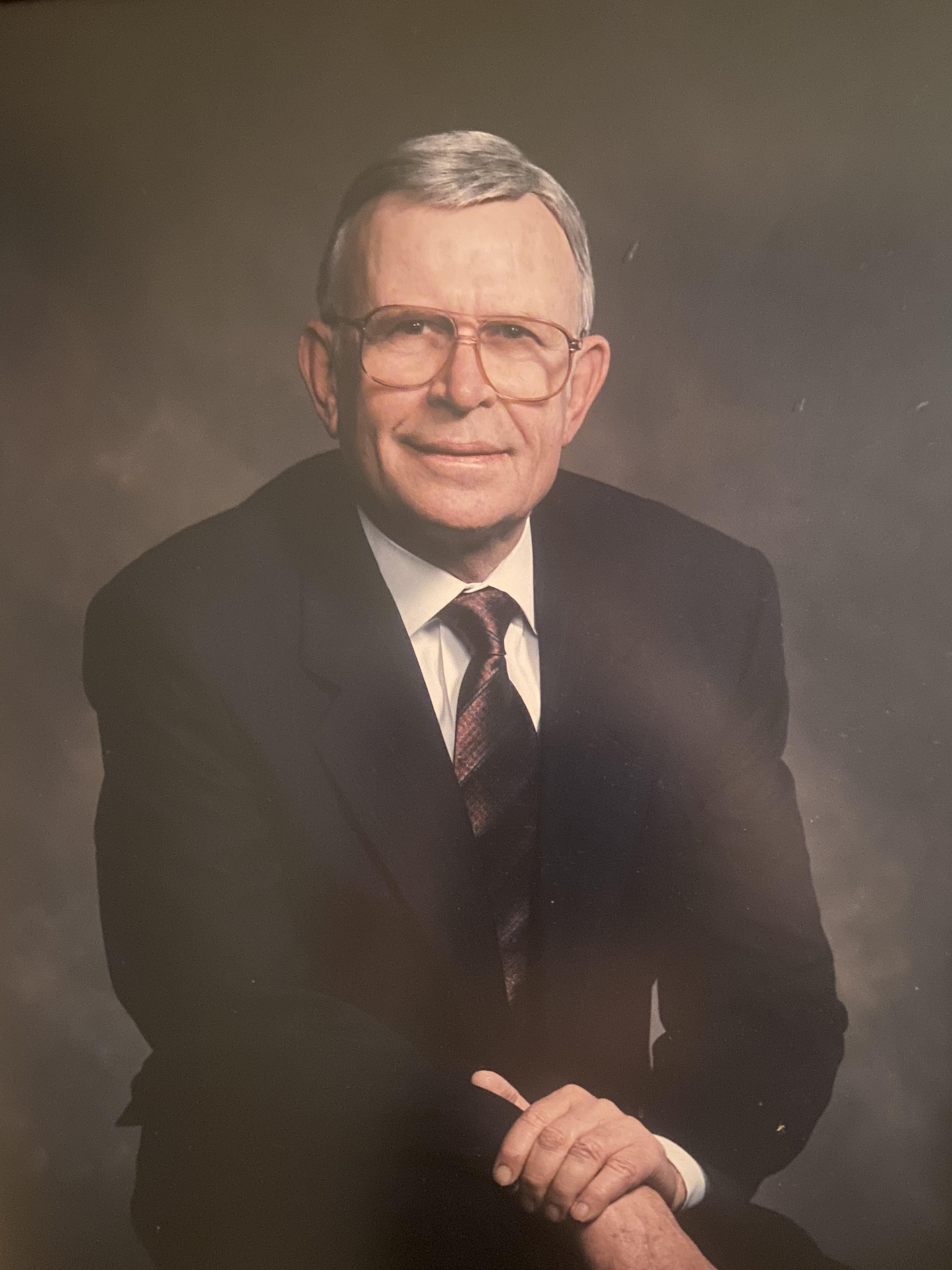

Pitts Enterprises founder Andrew Pitts passes

Andrew Pitts Jr.Pitts Enterprises

Andrew Pitts Jr., 90, founder and former CEO of Pitts Enterprises, died on July 16th.

Pitts built his first logging trailer in 1976 and went on to found Pitts Enterprises, which manufactures a variety of forestry trailers, hydraulic elevating loader carrier trailers, open and closed top chip vans and moving floor vans. The company continues as a family business under the leadership of Andrew’s son, Jeff Pitts, who has lead the company as CEO since 2002.

Iron Capital adds RPO option for used equipment

Iron Capital says it is making rental purchase options to its product offerings, designed to fill a gap between rental and purchase options.

The company says the RPO options give contractors the ability to rent with the option to buy that applies a portion of the rental payments towards purchase. Iron Capital says its approach is unique in the North American used equipment market.

Did you miss our previous article…

https://constructionosa.org/?p=15

BESCOM Recruitment 2021 for Apprentice (Graduate/Technician) | 30-07-2021

BESCOM Recruitment 2021 for Apprentice (Graduate/Technician) with 400 post vacancies, last date to apply is 30-07-2021

The post BESCOM Recruitment 2021 for Apprentice (Graduate/Technician) | 30-07-2021 appeared first on ConstructionPlacements.

Did you miss our previous article…

https://constructionosa.org/?p=14

JAX Bio-Guard Lubricants Protect Your Equipment and the Environment

The new line of Bio-Guard lubricants from JAX do what all lubricants do — protect equipment from friction and wear — but also protect the environment.

The complete line of Bio-Guard products meets the technical requirements established by the Environmental Protection Agency for biodegradability, toxicity and bioaccumulation.

In addition to states that have blanket rules on lubricants and the environment (like California), increasing numbers of industries, such as commercial marine, forestry, agriculture, hydroelectric power, construction and mining, are imposing their own rules.

JAX’s chemists and product development team focused on four key applications – wire rope, gearboxes, bearings and hydraulic systems. The products include:

JAX Bio-Guard Wire Rope Lube 00. Designed for rust and corrosion protection on steel wire rope and cables.JAX Bio-Guard Gear Oils. ISO 150 to 680. Designed for gearboxes used in outdoor environments.JAX Bio-Guard Hydraulic Fluids. ISO 32, 46, and 68. Synthetic, readily biodegradable lubricants designed to maximize hydraulic performance. JAX Bio-Guard Grease. NLGI 2 grease designed for areas where water resistance and load carrying properties are primary concerns.

Did you miss our previous article…

https://constructionosa.org/?p=13

Drum Rotates Up to 180 Degrees on Merlo DBM 3500 Mini Mixer

Merlo has introduced its new DBM 3500 Mini Cement Mixer to the U.S. market.

Along with its compact stature, the mixer is maneuverable on tight jobsites, able to discharge concrete up to 330 degrees around the machine. The drum can rotate laterally 180 degrees, and the chute provides additional reach.

The mixer also has a tight turning radius, and the drum has a reduced incline angle for further agility.

It can produce 37.7 square feet of concrete in less than 15 minutes, the company says. The 1,321-gallon drum can deliver 4.6 cubic yards of concrete. A self-loading bucket can handle up to 25 cubic feet of aggregate at each load cycle. Hydraulics lift and rotate the bucket as needed, while the door automatically opens to unload aggregate into the drum. The pump moves 66 gallons of water per minute into the mixing drum.

Merlo duplicated the in-cab controls outside the mixer at ground level. “From the ground, an operator can control engine acceleration, water pump activation, drum rotation, barrel lift, chute lift and emergency stop,” the company says.

The Merlo DBM 3500 Mini Cement Mixer can produce 37.7 square feet of concrete in less than 15 minutes, the company says.MerloThe ROP-certified, enclosed cab has double controls split between the front and rear. The front controls are for driving. The seat rotates 180 degrees to access the rear controls, which manage the mixing drum and self-loading bucket and also drive the vehicle. A lever reverses travel direction. Travel speed is up to 25 mph.

The mixer runs on a 100-horsepower Deutz diesel engine mounted on the side for increased ventilation and access.

Other features include four wheel drive with three steering modes, hydrostatic transmission, and portal axles for increased ground clearance of 16 inches. It is designed for any terrain, the company says.

The Merlo DBM 3500 Mini Cement Mixer can also be operated at ground level.MerloThe water tank has a 246-gallon capacity. Max unloading height is 7 feet.

The DBM 3500 is 12.7 feet high, 7.7 feet wide and 17.9 feet long.

It is sold in the U.S. through importer Applied Machinery Sales.

The hydraulic self-loading bucket on the Merlo DBM 3500 Mini Cement Mixer can hold up to 25 cubic feet of aggregate to load into the mixing drum.Merlo

Always check our latest articles at…

https://constructionosa.org//category/construction-management

Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!