Home » Construction Blogs (Page 4)

Category Archives: Construction Blogs

Video: Raising the U.S., Canadian Towers for the Gordie Howe Bridge

Construction progresses on what will become the longest cable-stayed main span in North America, on the Gordie Howe International Bridge between the U.S. and Canada.

And the construction is not without some patriotic spirit as this video by the Gordie Howe International Bridge Project shows of the rising of the Detroit-side tower between November 2020 and September 2021:

CMSBrowserComponents.load({ el: ‘#vue-1637339870827-259’, name: ‘OEmbed’, props: {“mountPoint”:”/__oembed”,”url”:”https://youtu.be/EJZFgBLve7U”,”attrs”:{“type”:”oembed”,”id”:”https://youtu.be/EJZFgBLve7U”,”element”:”aside”}}, hydrate: false });

The post-tensioning of the foundations for the two towers, one in Detroit and one in Windsor, Ontario, was completed in summer. Work continues on building the towers, which will each stand 720 tall.

The two towers’ temporary climbing systems, which rise as the towers rise, also currently depict images and colors to represent the U.S. and Canada, respectively.

On the Detroit side, the images include murals of an eagle, the “Spirit of Detroit” monument and an American flag with workers in the foreground – all on a blue background. The murals on the Canadian side depict the maple leaf, polar bears and other cultural scenes.

Check out this video by the Gordie Howe International Bridge Project of the tower construction on the Canadian side of the Detroit River between July 2020 and September 2021:

CMSBrowserComponents.load({ el: ‘#vue-1637339870827-503’, name: ‘OEmbed’, props: {“mountPoint”:”/__oembed”,”url”:”https://youtu.be/87RTDvGIbb4″,”attrs”:{“type”:”oembed”,”id”:”https://youtu.be/87RTDvGIbb4″,”element”:”aside”}}, hydrate: false });

A total of 1,426 steel strands were used to connect the tower footings on the U.S. and Canadian towers, according to the Windsor-Detroit Bridge Authority. Each strand is 236 feet long and weighs 519 pounds.

“The cables pull the footings together, so they work as one and handle the tower loads and eventually the road deck,” says Frank Raji, the bridge authority’s director of construction.

When the six-lane bridge opens, which is expected to occur in 2024, it will have the longest main span of any cable-stayed bridge in North America at .53 miles, according to the bridge authority.

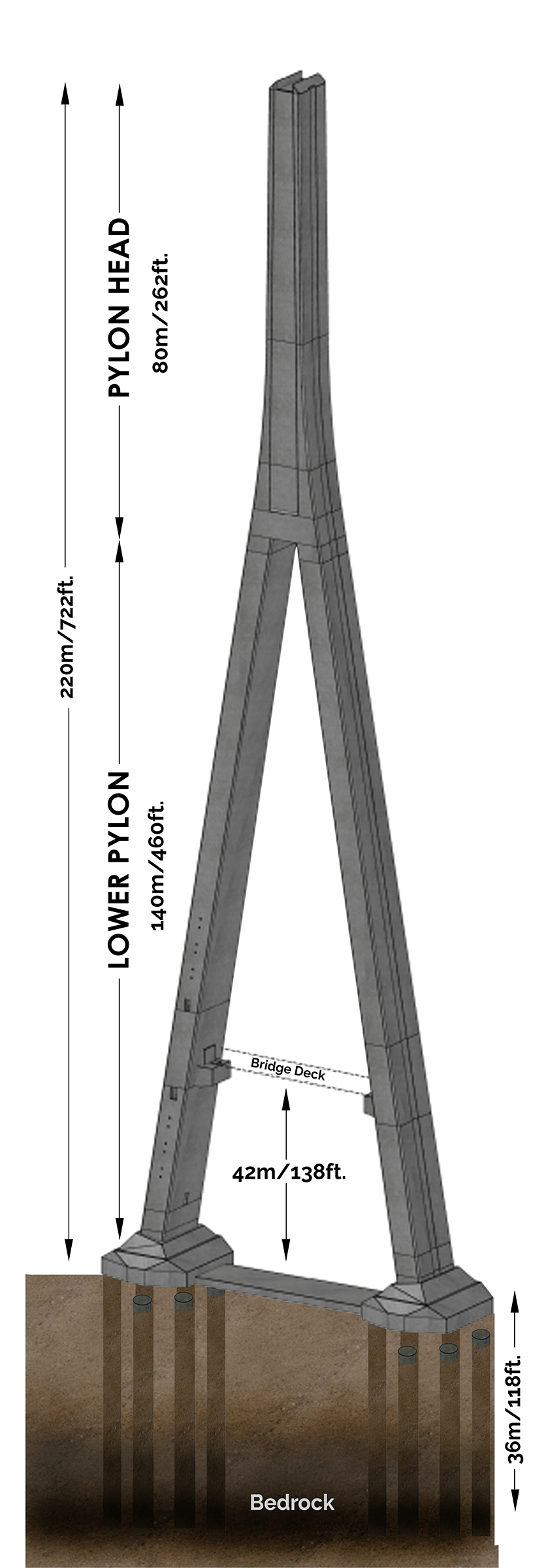

The towers are at about half the 722-foot height they will eventually reach. The road surface will be at 138 feet high.

The towers have an inverted “Y” design, with the top pylon head at 262 feet to house the 216-strand cable-stayed system.

The $4.4 billion bridge is being designed, constructed and will be maintained by a partnership of Fluor, ACS Infrastructure Canada and Aecon Group. Construction began in 2018.

Images below show the tower pylon designs and a rendering of the completed bridge:

The climbing systems for the U.S. tower feature murals by Detroit artist Roberto Villalobos.Gordie Howe International Bridge Project

A schematic drawing for the pylon design for the towers for the Gordie Howe International BridgeGordie Howe International Bridge Project

A rendering of the future Gordie Howe International Bridge, scheduled to be completed in 2024.Gordie Howe International Bridge Project

Did you miss our previous article…

https://constructionosa.org/?p=920

Arizona DOT Prepares to Build Flex Lanes, Widen Busy I-17 Near Phoenix

Work is set to begin next year on a three-year, $446 million widening of Interstate 17 north of Phoenix.

The project, which includes 15 miles of widening and 8 miles of new flex lanes, would alleviate congestion and improve safety, according to the Arizona Department of Transportation. ADOT recently awarded the contract to design, build, operate and maintain the expanded roadway to a joint venture of Kiewit Infrastructure West and Fann Contracting.

The DOT says the 23-mile section of I-17 between Anthem Way and Sunset Point carries 1 million travelers a year, with most traffic on weekends. Along with road widening and flex lanes, the project involves two bridge replacements, one bridge deck replacement and the widening of 10 bridges.

A map of the 23-mile project area to widen and add flex lanes to Interstate 17 between Phoenix and Flagstaff, Arizona.Arizona Department of TransportationThe 8 miles of flex lanes would be used during peak travel times and in emergencies. Drivers would pass through a gate to enter the lanes, which would be separated from the main highway lanes by a concrete barrier. The two lanes, on a mountainous, curvy section between Black Canyon City and Sunset Point, would carry travelers in one direction, with that direction switching to accommodate traffic needs.

For example, says ADOT, the flex lanes would be able to carry heavy northbound traffic on a Friday or heavy southbound traffic on a Sunday. They could also be opened in an emergency.

I-17 currently has two lanes of travel in each direction and provides a highway connection between Phoenix and Flagstaff, from I-10 to I-40. The 15 miles of roadway between Anthem Way and Black Canyon City would be widened an additional lane in each direction to four lanes. Then from Black Canyon City to Sunset Point, the two separated flex lanes would be added to the southbound road.

Here’s a video rendering by ADOT of how the flex lanes would work:

CMSBrowserComponents.load({ el: ‘#vue-1637356794241-417’, name: ‘OEmbed’, props: {“mountPoint”:”/__oembed”,”url”:”https://youtu.be/EbJNh2hlso0″,”attrs”:{“type”:”oembed”,”id”:”https://youtu.be/EbJNh2hlso0″,”element”:”aside”}}, hydrate: false });

Did you miss our previous article…

https://constructionosa.org/?p=917

Toromont reports 8% increase in revenues for Q3

Toromont Industries, based in Ontario, Canada, is reporting a revenue increase of 8 percent in the third quarter and 18 percent year-to-date.

“We are pleased with our operating performance, financial results, cash generation and financial position through a challenging business environment,” says Scott J. Medhurst, president and CEO. “The Equipment Group reported strong prime product deliveries and excellent order bookings. Rental activity and fleet utilization improved with more favorable markets. Tight supply of equipment from manufacturers coupled with stronger sales activity versus last year have resulted in lower equipment inventories.”

The company’s Equipment Group saw revenues up $389.1 million to $2.7 billion year-to-date with similar trends as the quarter. Strong equipment sales drove growth, while product support and rental activity continues to increase as well.

Driven by mining and construction, bookings increased 45 percent to $539.9 million in the quarter and 85 percent to $1.9 billion year-to-date.

Production timing and tight supply of equipment from manufacturers is beginning to drag out delivery to end customers. Backlogs were at $903.5 million as of September, an increase of 253 percent from the same time in 2020, according to the company.

“Activity remained sound as demonstrated by new bookings and our current backlog levels, but production schedules and supply chains are challenged,” says Medhurst. “This has restricted availability and is likely to result in delivery date extensions. We continue to monitor cost pressures, supply-demand dynamics and potential distribution disruptions as the pandemic unfolds.”

Toromont Industries’ Equipment Group includes Caterpillar dealer locations for the Canadian provinces of Newfoundland & Labrador, Nova Scotia, New Brunswick, Prince Edward Island, Québec, Ontario and Manitoba, in addition to most of the territory of Nunavut. The group also includes rental operations, an agricultural equipment operation and a material handling business. In addition to its Equipment Group, the company also designs and installs industrial and refrigeration systems through its CIMCO division.

Did you miss our previous article…

https://constructionosa.org/?p=890

Construction Groups Sue to Stop Biden Vaccine Mandate

Three construction industry groups have joined in the landslide of legal challenges to the Biden administration’s vaccine mandate for businesses with 100 or more employees.

They filed a petition for review November 15 with the 4th Circuit U.S. Court of Appeals, saying the mandate risks causing workers at larger construction companies to quit to work for smaller firms.

“Encouraging vaccine-hesitant workers to shift to smaller employers won’t improve health and safety,” said Stephen Sandherr, CEO of the Associated General Contractors. “It will just put firms that employ 100 or more workers at grave risk of losing the workers they need to complete projects.” The AGC is joined in the legal challenge with the American Road and Transportation Builders Association and the Signatory Wall & Ceiling Contractors Alliance.

The mandate is currently blocked from being enforced by the 5th Circuit Court of Appeals, which extended a stay of the emergency temporary standard issued by the U.S. Occupational Safety and Health Administration. OSHA’s standard would require employees of companies with 100 or more workers to get vaccinated by January 4 or undergo weekly Covid testing. Unvaccinated workers would also have to wear masks at work starting December 5.

The 5th Circuit opined November 12 that OSHA overstepped its authority, and that “the mandate has contributed to untold economic upheaval in recent months.”

The construction industry groups reiterated that position in their legal challenge. They also note that 64 percent of construction jobs are with smaller companies, and with the current labor shortage, employees at larger firms have plenty of options to move to smaller ones.

“The Biden Administration and Congress are in the process of launching a historic federal infrastructure investment initiative,” ARTBA President Dave Bauer said. “Unfortunately, OSHA’s proposal would disproportionally impact the same transportation construction industry employers and workers who proved they could safely deliver essential mobility improvements during the height of the Covid-19 pandemic.”

OSHA’s response to the 5th Circuit petition says the emergency standard “is necessary to address a grave danger” and that the “legal objections lack merit.”

OSHA has argued that the emergency standard is not a mandate because employees have a choice on whether to get vaccinated or get tested.

The standard does not require employers to pay for weekly Covid testing, and Covid vaccines are free. However, employers would be required to pay for time off for workers to get tested and vaccinated, as well as time off for any side effects from the vaccine.

The construction groups say they are supporting successful promotion efforts to get workers vaccinated, but the mandate would have the opposite effect.

“This industry supports the coronavirus vaccine and is working to get as many workers vaccinated as possible,” said Scott Casabona, spresident of SWACCA. “But crafting an unworkable rule that will do little to get construction workers vaccinated is an approach that is not only wrong, but likely counterproductive.”

A random drawing is expected to be held this week to determine which appeals court will hear the case, according to NPR. The cases will be consolidated into one.

Did you miss our previous article…

https://constructionosa.org/?p=868

Industry Roundup: Hydrogen-Fueled Equipment to Come in 2022

Hydrogen-fueled equipment to come in 2022

JCB is investing $138 million on a project to produce carbon-free hydrogen engines, the company announced last month. The first hydrogen-fueled machines will be ready for customers by the end of 2022.

According to JCB Chairman Lord Bamford, the company is investing in hydrogen because electric power has limits and is not an all-around solution, especially when it comes to larger machines. “We will carry on making engines, but they will be super-efficient, affordable, high-tech hydrogen motors with zero CO2 emissions, which can be brought to market quickly using our existing supply base,” says Bamford.

The company has already shown a prototype hydrogen-powered JCB backhoe loader. A second JCB machine – a Loadall telescopic handler – was unveiled October 19 at an event in London attended by Prime Minister Boris Johnson.

Firmatek acquired Kespry’s drone-based aerial intelligence platform.BuildwittDrone maker Kespry bought by Firmatek

Two leaders in the world of drone applications for the construction, mining and aggregate industries have joined forces. The combination of Firmatek’s drone-data processing and engineering services with Kespry’s drone-based mapping intelligence platforms will create new opportunities to deliver a vertical SaaS platform for drone-based analytics.

The acquisition will accelerate the use of artificial intelligence technologies and deep-learning frameworks to analyze and process topographic analysis of mining and aggregate worksites, increase data accuracy, improve site safety and eliminate potential risks.

“By combining Firmatek’s resources with Kespry’s expertise and leadership in AI-driven, SaaS software, we can provide better outcomes for our customers,” says Lauren Elmore, Firmatek’s chief executive officer.

Equipment World has reported on Kespry’s offerings several times in the last few years. To learn more about its technology, check out the links below.

With three big updates, Kespry gives construction customers little reason to take their drone data elsewhere

John Deere dealers to offer Kespry’s automated construction drone service in exclusive deal

Kespry Drone 2s brings centimeter-level survey accuracy, single base station setup to automated drone platform

Tag tools and attachments with the Kin asset tracking system and you’ll always know where they are.TrackunitIf you can’t find a tool, try checking your Kin

Everybody knows that workers waste significant amounts of time searching for lost equipment. And according to Trackunit, only one out of five lost tools are ever found. One solution, announced at the ARA show in Las Vegas, is Trackunit’s new Kin Asset Utilization, which collects movement data from tagged assets and shows you in real time if the equipment is being used.

The Kin ecosystem resides within a platform to greatly increase the scope of data available to users and organizations and continues to enhance solutions in an ever more data-led construction market.

The Kin tags leverage the company’s mesh network and connect to the company’s Raw (TU600) installed network of devices via the Trackunit Manager and the Trackunit Go app. Each connected tag links to the TU600 network installed on machines around the globe, connecting the user and expanding the data available for business insights.

Couplers and work tools bearing this logo can work with any excavator from OEMs that are members of the Open-S Alliance.Open-S AllianceVolvo joins Open-S Alliance

Recently Volvo announced it has joined the Open-S Alliance. The alliance is a group of manufacturers that have agreed to design hydraulic attachments in such a way that their quick couplers and adaptors will work with any excavator regardless of the brand of the machine. This makes it easier for contractors to use different couplers, tiltrotators and work tool brands without being locked into a proprietary solution from one manufacturer.

The Open-S Alliance is a manufacturer-independent organization. There are three levels of membership: full, associate and supporting, depending on if Open-S products are developed, produced in-house or sourced. Since early 2021, Volvo CE has delivered quick couplers and adaptors directly from the factory and is now joining the Open-S Alliance as a supporting member.

Survey says data driving AEC transformation

More bricks than bytes, construction has been slow to adopt digital technology. But that is changing, according to a new report from Dodge Data & Analytics and Autodesk. The study finds the most frequently used BIM (building information modeling) technologies by architecture, engineering and construction firms are cloud computing (42%), model-based simulation (33%), virtual/augmented/mixed reality (28%), 3D printing (25%) and reality capture (25%).

The technologies best poised for growth, with a relatively high percentage of respondents who expect to adopt them in the next two to three years, include generative/outcome-based design (20%), 3D printing (19%), model-driven prefabrication (18%), model-driven simulation (18%), robotics/automated equipment (18%), reality capture (17%) and AI/machine learning (17%).

More details the free report can be accessed at www.construction.com

Did you miss our previous article…

https://constructionosa.org/?p=852

LiuGong Gears Up to Take on U.S. Construction Equipment Market

As supply-chain problems tighten construction equipment availability, LiuGong North America in Katy, Texas, says it has a compelling message to customers and potential dealers:

We’re here, we’re growing, and in some cases, we have inventory.

Earlier this year, LiuGong detailed a major revamp of its offerings to U.S. customers, including a transition from the E-series to the F-series excavators, a new line of Dressta dozers scheduled to debut in the second half of 2022 and the introduction of new wheel loaders over the next 24 months. This fall, the company had select models including its new F-series compact excavators displayed at both the Utility Expo and the ARA Show.

During the shows, Equipment World sat down with the LiuGong executive team to catch up.

With most of its products manufactured in China, LiuGong is seeing the supply constraints impacting the construction equipment industry. “I’ve not seen anything like this in 29 years of being in the industry,” says Kevin Thieneman, executive chairman and vice president. “We have to choose what we ship from month to month because you can’t get space on ships.”

Still, because China recovered earlier from the pandemic’s impacts and because more Chinese production is now directed overseas as domestic demand lessens, LiuGong North America finds itself in a better position than some of its competitors. It has inventory for sell, albeit much of it spoken for when it comes off a ship.

Take, for instance, LiuGong’s new F-series compact excavators, which LiuGong has limited inventory. “Availability equals retail at this point,” says Chris Saucedo, vice president and general manager, construction equipment, “and so just about everything that’s coming off the boat is already spoken for, and our dealers are working with each other to fill needs and get more business.”

Dealers, dealers, dealers

The green areas in this map indicate locations that LiuGong North America is targeting for dealer acquisition. (As of September, 2021; Alpha & Omega in Texas has since signed on.)LiuGong North America

Job number one for LiuGong North America is to strengthen its dealer network, says incoming president Andrew Ryan. “We have representation in about a third of the most important North American markets. We want to rapidly increase our representation, not by adding just numbers of dealers but by adding quality dealers that believe in our brand story.”

LiuGong is specifically looking for dealers in the Southeast, Pennsylvania and the central Midwest, among others. (See map above.)

“We don’t have any hard and fast rules about working with LiuGong at the expense of working with others,” Ryan says. Multiline dealers, he says, have an existing infrastructure that allows the company to build incremental relationships. “When you’re in a multiline dealer environment and that dealer is deciding to make an inventory investment with us or a competitive brand, that sharpens you.”

LiuGong’s vision here is to become a full-line OEM. Potential U.S. products waiting in the wings in the company’s plants in China include motor graders, compactors and backhoes. (LiuGong already sells Tier 3 versions of several products in Mexico.)

Another thrust for Ryan is to grow LiuGong North America’s aggregates business. “We’re asking our dealers to be prepared for expansion of our line into larger products over the next three to five years, specifically wheel loaders and excavators and, eventually, 100-ton rigid-frame haul trucks,” he says.

“Quarry and aggregates have been a great success for us,” Thieneman says, who also points out that KHL’s Yellow Table now ranks the global company as the 15th largest construction equipment manufacturer in the world, with more than $4 billion in sales revenues in 2020.

Another thrust is rental. The company has about 30 distributors, and about half of them are in the rent-to-sell space with a few in rent-to-rent. “It’s likely we will complement our dealers’ rent-to-sell strategy with certain regional account customers,” Ryan says. “We can be a very good supplier to a midsize regional rental company.” And in areas where there is no current dealer coverage, “there will be big opportunities for us to form relationships with rental companies, and perhaps see them choose to represent us as a dealer over time.”

Ryan is also working on building the North American team. “We want to make sure they feel empowered and entrepreneurial,” he says. “It’s a very different environment in this startup space than it would be with one of our more mature competitors. This is a see-a-problem-solve-a-problem kind of place.”

LiuGong also wants its dealers to know the brand’s clear expectations of product support. “You have to have buyer confidence that you’re going to be there long term after the sale,” Ryan says. “You’ve got the parts stocked, the technicians and the service infrastructure to keep customers running and productive.”

Head-to-head with the big guys

LiuGong’s 835 wheel loaderLiuGong North America

For those who hesitate to buy a Chinese-made machine, Thieneman points out that LiuGong produces global equipment. It uses Cummins engines and ZF transmissions. “When you break it down that way, it then becomes a question of dealer support.”

Moreover, the company will put its compact excavators “head-to-head with the big guys,” Saucedo says. “The product is very strong.” The 1.8-metric-ton 9018F and 2.7-metric-ton 9027F started arriving earlier this year. LiuGong will also introduce two additional models, the 4.5- and 5.5-tonne units, that will round out the F-series line, says Saucedo. The full-size excavator offering is now in transition, with the last E-series machine sold in September. The F-series full-size excavators will appear early next year.

Although LiuGong expected its revamped Dressta dozers to first make their appearance this fall, that schedule has been pushed back to Q2 next year. It now has five machines in a test program here.

Ryan comes to LiuGong after 25 years at Caterpillar where he worked on Cat’s expansion into the rental and compact equipment segments, along with working with dealers and in aftermarket parts. After a two-year stint in financial technology, Ryan returned to construction, signing on with LiuGong in late summer.

“We have that startup energy and the excitement of creation combined with the experience and financial capacity of a global brand,” Ryan says of LiuGong.

Patriotic Telehandler Supports Veterans Organizations

EquipmentShare’s Genie GTH-1056 donning an American flag and military fatigue wrap is more than just a patriotic tribute to veterans and service members. Nicknamed “Tele-Hero”, 10 percent of the telehandler’s rental proceeds will be donated to Welcome Home Inc. and Hire Heroes USA, organizations that help veterans find safe housing and employment resources.

EquipmentShare expects to donate more than $3,400 annually from Tele-Hero’s rental proceeds alone. The initiative is part of the company’s broader philanthropic mission and workforce development initiatives that include supporting and hiring those who wore the uniform.

“I and the rest of the Genie team take great pride in supporting our customers and equipment rental partners with quality equipment that achieves their business goals,” says Genie president Simon Meester. “We are especially proud when it supports a deserving cause like honoring our veterans, and we are honored that EquipmentShare selected the GTH-1056 for its Tele-Hero initiative.”

“We hope that the Tele-Hero demonstrates our commitment to veterans and serves as a call to action for more employers to open their doors and offer fulfilling work to our heroes,” says EquipmentShare CEO and co-founder Jabbok Schlacks.

During the unveiling, U.S. Air Force Senior Airman Mark Ayers was present to accept a full-time position at EquipmentShare’s Tyler, Texas, branch. Ayers worked with Hiring Our Heroes and the Department of Defense’s Skillbridge program to be placed in an internship with EquipmentShare during the final months of his active duty military service.

EquipmentShare is currently developing its own workforce development programs to encourage veterans and service members to explore employment opportunities in the equipment and construction industries.

Did you miss our previous article…

https://constructionosa.org/?p=833

New Ford e-crate Motor in Electric F-100 Eluminator Sold Out in 4 Days

If you didn’t move fast enough on Ford’s new e-crate motor, you’re out of luck.

The all-electric powertrain featured in Ford’s concept F-100 Eluminator pickup at SEMA sold out just four days following its debut at the Las Vegas Convention Center.

The 480-horsepower electric pickup truck based on a 1978 F-100 cranks out an impressive 634 pound-feet of torque, thanks to Ford Performance Parts’ very first e-crate motor.

“Ford owners have personalized, customized and enhanced their vehicles since the beginning – from changing looks to bringing the power,” said Eric Cin, global director of Ford’s vehicle personalization, accessories and licensing. “Our F-100 Eluminator concept is a preview of how we’re supporting customers as they go all-electric and embrace zero-tailpipe emissions performance, even for our heritage vehicles.”

Don’t be fooled by the e-crate motor’s small size. It puts out 480 horses and 634 pound-feet of torque.Ford Performance PartsThe all-electric F-100 Eluminator concept, designed and created by Ford Performance, was built in collaboration with MLe Racecars and sits on a custom chassis by the Roadster Shop.

It’s painted in Avalanche Gray with Cerakote Copper accents applied by Brand X Customs, while the interior features a billet aluminum dash by JJR Fabrication and avocado-tanned leather upholstery by MDM Upholstery. It’s fitted with custom 19×10-inch billet aluminum three-piece wheels by Forgeline wrapped in MichelinLatitudeSport 275/45-19 high-performance tires.

Part No. M-9000-MACH-E, the e-crate motor was available for a few short days at authorized Ford parts warehouse dealers or online at Ford Performance Parts. Retailing at $3,900, it is targeted for builders looking for a transverse-oriented powertrain to electrify a range of vehicles from modern to vintage cars, trucks and SUVs.

Each Eluminator e-crate motor produces 281 horsepower and 317 pound-feet of torque and is street-legal in all 50 states.

Did you miss our previous article…

https://constructionosa.org/?p=822

Stellar’s New Lightweight Service Body Handles 4,000-Pound Crane

Stellar has rolled out a new lightweight, corrosion-resistant truck service body that can handle up to a 4,000-pound crane.

Designed as a mechanic’s field truck for utility and construction contractors, the new TMAX 16K aluminum service body can be equipped with Stellar’s EC3200 Aluminum Telescopic Crane, which weighs 500 pounds, 230 pounds less than its steel counterpart. The compact aluminum telescopic crane delivers 3,200 pounds of lift capacity and 15 feet of horizontal reach.

The lighter weight of the crane and service body allow for increased truck payload, the company says.

“We’re all about trying to get more payload options for people,” said Adam Opperman, Stellar product manager, at the Utility Expo in September. “So that’s why we do aluminum; it’s lighter than steel, and it’s also more corrosion resistant than steel.”

Stellar’s Light-Duty Mechanic Cranes are powered, controlled and monitored by the hand-held, remote-control Stellar Crane Dynamics Technology.

Stellar’s EC3200 aluminum crane can lift 3,200 pounds.StellarThe TMAX series includes an aluminum extrusion compartment top that has two built-in accessory mounting rails, so you don’t have to drill holes to mount equipment. The rails make removing and attaching accessories easy and reduce water intrusion into the compartments, according to Stellar.

The extruded compartment top also has wire harness channels inside the compartments for storing wires out of the way. Other features include stainless-steel billet style hinges, three-point stainless-steel compression latches, double spring over center door closures and undercoating for corrosion resistance. The body is painted with a two-part polyurethane enamel paint for added protection and visual appeal, according to Stellar.

Contractors who need a welder body might also want to check out Stellar’s TMAC 1-11, which features a 30-inch workbench bumper with slide-out tray to serve as a workstation for torch cutting and welding.

“The trays’ removable support slates allow for blow-through to the ground, keeping your workspace clean, and the 2-inch V channel that run the length of bumper make for easy clamping,” the company says.

The welder body is equipped for Stellar’s TC Series Cranes, which also use hand-held remote control.

Stellar TMAX 1-11 Welder BodyStellar

Did you miss our previous article…

https://constructionosa.org/?p=818

Fixing “Malfunction Junction”: Work to Begin on SC’s Biggest Infrastructure Project

South Carolina’s “Malfunction Junction” will eventually earn the name of “Carolina Crossroads” as work is scheduled to begin this month on untangling the congested, dangerous interchange at I-20, I-26 and I-126 in Columbia.

The reconstruction – South Carolina’s largest infrastructure project in its history – is estimated to cost $1.7 billion and take eight years to complete. Gov. Henry McMaster and other dignitaries attended a groundbreaking Monday, and the SCDOT says work will begin in two weeks.

The work involves widening 14 miles of interstate highway in five phases. A joint venture of Archer Western and United Infrastructure won the $210 million contract for the first phase. It will include reconfiguring the Colonial Life Boulevard interchange on I-126, as well as improvements on I-26 toward U.S. 378.

Archer-United also won the $127 million contract for the second phase, which will update the Broad River Road interchange at I-20 and lengthen the I-20 westbound access to I-26 West. Both phases are expected to be completed by the end of 2024. The remaining three phases have not yet been awarded.

The rebirth of “Malfunction Junction” into Carolina Crossroads will occur in five phases.SCDOTAlong with widening 14 miles of interstate, the entire project involves building 43 new bridges and 132 new lane miles; reconstructing seven interchanges, including replacing outdated cloverleaf loops with modern ramps; and creating safer interchange exits that are farther apart and separated from other interstate traffic, according to SCDOT. The project is funded 90% federal and 10% state.

The three-interstate interchange is traveled by more than 134,000 vehicles each day, SCDOT says, causing more than 112 hours of traffic delays each year due to congestion.

The roadways are outdated, built in the 1950s and 1960s with the last updates in the 1970s and 1980s, according to SCDOT. The region is also expected to see a 70% population increase by 2024, causing even more traffic congestion. The agency says the interchange sees a higher crash rate than other freeway-to-freeway systems in the state.

Did you miss our previous article…

https://constructionosa.org/?p=812