Home » Construction Services (Page 4)

Category Archives: Construction Services

Work Begins on Freeway Outer Loop for Lubbock, Texas

Work has begun on what will eventually become an outer loop around Lubbock, Texas, starting with transforming a two-lane rural road into a six-lane freeway.

The entire seven-phase project, expected to take 20 years to complete, has been in planning for more than 10 years, according to the Texas Department of Transportation. On November 8, the department held a groundbreaking on the first two construction phases, covering 4 miles of the planned 36-mile loop.

Phases 3A and 3B are expected to take up to five years to complete at a cost of $155 billion. Sacyr Construction USA of Miami won the construction contract.

The project involves transforming FM 1585 into a freeway with frontage roads, bridges and ramps. The current road handles about 50,000 to 60,000 vehicles a day, and the loop is designed to handle future traffic for the growing city.

Crews will begin work by creating retention ponds at four locations before beginning work on an underground drainage system, according to TxDOT. The DOT plans to keep one lane of traffic open in each direction throughout construction.

Phases 3A and 3B are the first of seven phases along the 12.4-mile Segment 3 of the Loop 88 corridor. Segment 3 extends from U.S. 87 to U.S. 62/82 in Wolfforth and will cost an estimated $600 million.

Phase 3C, which includes the U.S. 87 interchange, is scheduled for construction to begin in 2026.

“We’re excited to finally turn dirt and see the hard work the TxDOT Lubbock District has put into research, public meetings and roadway designs becoming a reality,” said Michael Wittie, TxDOT Lubbock area engineer.

Lubbock Loop 88 will eventually create an outer loop around the west and south areas of Lubbock. Its construction phases are broken down into four segments, with each segment having five different sections. Bid lettings for future phases of Segment 3 are scheduled out until October 2031.

Did you miss our previous article…

https://constructionosa.org/?p=896

These 14 Skid Steer, CTL Attachments Go Beyond Mere Material Handling

As the number and popularity of compact construction equipment continue to grow, so do the outpourings of attachments for performing a wide range of tasks beyond moving material.

You can turn you skid steer or compact track loader into a snowblower, landclearer, earthmover and even a demolition machine.

So if you want to expand the range of your skid steer or CTL beyond loading and unloading material, check out these 14 attachments:

Earthmoving

The Dual Dozer laser grading system (pictured at the top of this story) from HitchDoc for finish grading features a dual-sided cutting edge so you can push or pull material and grade in any direction. Rear-mounted wheels let you bring more material to low spots, make tight corners and place material closer to edges. The Dual Dozer can be ordered with a standard quick-tach plate, three-point mount or both. It is compatible with Trimble, Topcon and Leica 3D or GPS mapping systems. The blade attachment can self-articulate up to 8 inches on either side. It comes with in-cab monitors and fingertip switches.

Danuser Stump Auger with EP Auger SystemDanuserDanuser’s new EP Auger System, which is compatible with the company’s new Stump Auger, is now available for mini skid-steers, also known as compact utility loaders, with a planetary gear drive that is up to 42% stronger with greater torque for drilling through hard-compacted surfaces. Models range from 6 to 35 gallons per minute of hydraulic flow and from 1,500 to 3,500 psi. The Stump Auger is available in 10- or 16-inch diameters. A threaded pilot digs into the stump, and large cutting blades shave it away. The blades are reversible.

General Equipment’s 471 DIG-R-TACHGeneral EquipmentGeneral Equipment Company’s 471 DIG-R-TACH hydraulically powered earth drilling attachment system is designed for use with machines with lower auxiliary hydraulic flow rates. It comes with a universal mounting bracket that matches a variety of bucket configurations. It can be mounted quickly and easily on the loader’s bucket by one person without special tools, drilling or welding because of positive-locking bracket grips. Augers are available in diameters of 2 to 24 inches to produce a clean 4-foot-deep hole. Auger extensions are also available

Landclearing

Fecon RK6015 standard-flow skid steer mulcherEquipment WorldFecon’s new RK6015 mulcher is designed for standard-flow skid steers and CTLs of 50 to 75 horsepower and can chew through brush and trees up to 5 inches in diameter. The RK6015 has a working width of 60 inches and includes a split-ring design to limit the bite and maintain production. Features include a variable displacement 45cc hydraulic motor and adjustable bolt-on push bar with serrated ears for directing material. Flow ranges are 17 to 27 gallons per minute, and max pressure of 4,000 psi.

Takeuchi TUML forestry mulcherTakeuchiTakeuchi’s TUML series Forestry Mulchers come standard or with bite-limiter drums, which limit tooth engagement to maintain motor speed while reducing stalling. The mulchers feature a low-profile frame design for better visibility and an enclosed door drive that prevents dirt from entering the machine’s service areas. Heavy-duty adjustable skids and reinforced side panels deliver durability and frame strength to handle the force of the carrier. The mulchers’ design with a protruding rotor allows more material to be processed quicker.

Loftness Bad AxLoftnessLoftnessBad Ax disc mulcher is designed for landclearing and vegetation control and cutting through trees up to 14 inches in diameter. The 60-inch-diameter disc contains no welds, so there are no areas subject to stress cracking. The disc is driven directly by the machine’s hydraulic motor. A recutter bar and counter teeth hold material in place while it is being mulched, enabling the mulcher to cut the material into fine particles and avoid jams in the chamber. The front of the housing is angled, allowing the teeth to mulch at ground level.

Snow clearing

New Bobcat SnowblowerBobcatBobcat’s new snowblower attachment features increased intake height and a bigger auger to draw more snow into the blower for faster clearing and fewer passes. A direct-drive, sprocket-style chute rotation enables operators to point snow within 270 degrees for precise placement, even in hard-to-reach places such as ditches or inside wooded areas. It can break through ice buildup and does not use chains, which can rust, loosen or break. The chute’s rounded, smooth intake minimizes clogging and reduces resistance. A truck-loading chute is optional.

Fisher HDX snowplowFisherThe HDX straight-blade snowplow from Fisher is designed for fast, easy hookup. Its adjustable blade attack angle lets you customize your setup to plowing surfaces, weather conditions and plowing preferences. The blade angle is powered by the host machine’s hydraulic components. Relief valves protect the operator and the equipment when encountering hidden obstacles. The HDX can be used to clear large parking lots and can maneuver between cars and parking islands.

SnowEx Power TE steel trip-edge pusherSnowExThe SnowEx Power TE steel trip-edge pushers are designed to attack all types of surfaces and provide cleanly scraped, “down to black” pavement. The box plows attach quickly and easily to compact equipment and offer large carrying capacities. Built to handle heavy-duty loads and stresses, the trip-edge uses four extension springs along with two outer double ribs at the trip springs. The box comes in widths of 8 or 10 inches and a 63-degree angle of attack.

Western Prodigy snowplowWesternThe Western Prodigy skid steer snowplow features wings that move automatically with no additional wiring or controls. The universal skid-steer mounting plate makes hook-up fast and easy. Simply align the mounting plate with the skid-steer u-plate, engage the pins, and you’re ready to plow. The plow uses the skid steer’s hydraulic system to lift and lower the blade. It’s also available with an optional oscillating mount that provides 6 degrees of total side-to-side oscillation, helping to improve scrape and cutting-edge wear while reducing damage to the terrain.

Demolition

NPK demolition shearNPKNPK Demolition Shears are sized for skid steers ranging in the 5,000- to 6,500-pound class for demolition and steel-processing operations. The arm pin is designed to prevent distortion of the main frame and diminishes jaw deflection, which prevents material from jamming between the cutter blades. The shears features 360-degree rotation, low weight with large jaw opening and a slim design for better visibility. The cutting blades are wave shaped for better grip and control of material. The shears can also be used on compact excavators of 7,000 to 20,000 pounds.

RJB Hydraulic HammerRJBRJB Hydraulic Hammers’ new Skid Steer/Mini Combo Bracket works with both skid steers and compact excavators of 3.5 to 6 metric tons. The bracket allows the company’s HK45 hydraulic hammer to be used on both a skid steer and a compact excavator. The HK45 is in the 1,000-foot-pound impact class for work on larger concrete jobs. It comes with a tool diameter of almost 3 inches. The combo bracket enables the operator to simply detach the skid steer plate by pulling out the pin set, which takes less than 5 minutes. Re-installing the skid steer plate is just as easy, the company says.

Sweeping

Virnig’s Internal Water Tank BroomVirnigWhen it comes time to clean up your jobsite, Virnig’s Internal Water Tank Broom for skid steers controls dust as you sweep. The protected 55-gallon tank behind the bucket provides 35 minutes of continuous runtime. The translucent tank has capacity indicators so water level can be viewed by the operator while in the cab. The guarded adjustable valve regulates water pressure to the nozzles. The broom is available in 72 or 84 inches. Features on the broom include a recessed and guarded direct drive motor, heavy-duty bucket with wear bars, bolt-on edge, oversized 2-inch bearing, poly/wire bristles and pin adjustment system.

Quick attach

Artillian Tractor quick attach frame for mini skid steersArtillian TractorArtillian Tractor has a new Mini Skid Steer Quick Attach Frame for compact utility loaders. The frame can handle loads up to 3,000 pounds and can be used with Artillian pallet forks, grapples, stump buckets, hydraulic plow and other tools. The frame uses the Common Industry Interface loader quick attach and fits major CUL brands, including Bobcat, Boxer, Cormidi, Ditch Witch, Kanga, Ramrod, Toro and Vermeer. The Artillian frame features metal inert gas welded construction, baked on powder coat and high-strength North American steel.

Did you miss our previous article…

https://constructionosa.org/?p=875

Cat Next Gen Medium Wheel Loaders Pack a Technology Punch

Caterpillar has updated its 8- to 10-ton wheel loader line with a slew of standard technology features aimed at reducing maintenance costs, increasing operator productivity and improving fuel efficiency. Models joining the Next Generation lineup include the 966, 966 XE, 972 and 972XE.

“Every industry is seeing a shortage of labor. Anything that we can do to make these machines easier to operate, bring novice operators in, train them up and make them productive as soon as possible is where we’re focused on helping the industry,” says Bryan Cherry, Caterpillar global product marketing consultant.

The new machines ditch the lettered nomenclature and replace the M-series loaders unveiled in 2013 and upgraded in 2016.

All four models are powered by a Cat C9.3 B engine. The 966 and 972 models use smart technology to move more tons of material per hour, increasing productivity by up to 10 percent.

The 966 XE and 972 XE models use a continuously variable transmission (CVT), resulting in 35 percent better fuel efficiency than the standard transmission M-series. Prolonged service intervals plus efficiencies gained through the CVT powertrain result in even lower maintenance costs of up to 25 percent, further reducing operating costs.

Technology boosts efficiency, productivity

No more worrying about under- or overloading trucks leaving the yard. All four models feature standard Cat Payload with Assist. Operators can load to target the first time every time.

“The highest instantaneous fuel burn of a loader cycle is during the dig, not while traveling around,” says Scott Schmidtgall, Caterpillar product application specialist. “Assist features are focused on reducing fuel burn, getting more material in the bucket and lessening operator fatigue.”

Auto Set Tires reduce tire slip and wear by promoting proper loading techniques. “As you go into the pile, it provides lift command to set those front tires to make sure you have traction and that you’re not slipping, making for more efficient operation,” says Cherry.

Pair Auto Set Tires with the new Cat Autodig and the job becomes almost effortless. Autodig will automate the entire dig cycle from entering the pile all the way up through where you want to dump into the truck or whatever height you want to stop at. It’s a feature that benefits novice and experienced operators alike.

“You can put your senior operator in that cab and go through and record in Autodig. Then, put your new person in and he or she can see exactly what that 20-year veteran just did and how they got their bucket full,” says Cherry. “Or if you’re an expert operator and you go get that full bucket in the morning – and don’t want to have to do those controls – you can just replay that dig all day long.”

Optional Cat technologies help to further increase productivity and operation profitability of the updated series. Tip Off Assist helps operators hit the right tonnage every time. “Push a button and hit dump and that machine is going to tip the material off for you,” says Cherry. “It’s going to tip until it hits 10 tons. It’s going to rack back telling you that it’s done, and now you’ve accurately hit that last pass. It takes all the guesswork, all the anticipation and all the mental awareness from the operator out of the equation.”

Built with safety in mind

The most important thing on the jobsite is keeping people safe, and the Next Gen wheel loaders come with several new and enhanced features to increase visibility and awareness.

A high-definition rearview camera comes standard, or contractors can upgrade to the multi-view vision system for a 360-degree view around the machine.

Cat Detect radar technology is another optional feature for those looking to take safety to the next level. “Think of your car. We have radar out the back of the machine, so when you go in reverse, it is identifying any objects that are behind you and giving an audible alarm and a visual alarm in the cab,” says Cherry.

Standard monitored seatbelts can be enhanced with an exterior beacon to allow for easy checks of proper safety procedures. “There’s a green light in the cab and behind it. When you click your seat belt on, that green light illuminates,” says Cherry. “It’s very easy for a jobsite superintendent to drive around the site and know if that operator is wearing their seatbelt or not.”

Optional service lighting and access lighting allows operators to see in and out of the cab during those late-night and early morning shifts.

Fuel efficiency and performance

Productivity sees a bump while fuel burn continues to trend down on the Next Gen wheel loaders. Increases in performance and fuel efficiency in the 966 XE and 972 XE are made possible through the Integration of the CVT powertrain, engine, hydraulic and cooling systems.

The H-series released in 2005 averaged 5.75 gallons of fuel burned per hour. Today’s 966 XE averages 3.1 gallons per hour – that’s a 45 percent reduction over the H series and a 15 percent reduction over the M-series with powershift transmission.

Without the torque converter of mechanical drive systems, these loaders independently control engine rpm and machine speed to provide efficient digging, fine control and operation. Operators will experience smooth, fast accelerations and high speeds on grade with the CVT design. Speed-hold and anti-rollback features also enhance machine maneuvering on grade.

Advanced rimpull control helps to reduce tire wear and delivers optimal loading efficiency in the pile. Beyond saving fuel, the lower rated engine speed of the XE models reduces component wear and makes for quieter operation.

Less downtime ahead. The 500-hour service intervals have been eliminated on the 966 and 972 next generation wheel loaders.Equipment WorldMaintenance savings

Next Gen loaders can spend more time at work thanks to extended maintenance intervals for fluids and filters. The 966 and 972 series design extends maintenance intervals to 1,000 hours and eliminates the 500-hour service intervals.

An integrated optional Autolube reduces daily maintenance and increases component service life, while convenient access to hydraulic and electric service centers makes servicing the loaders fast and easyCombined, these design updates reduce maintenance costs up to 20 percent for the Cat 966 and 972 models and up to 25 percent for 966 XE and 972 XE loaders.

Technology also plays a role in improving loader servicing. Helping to manage fleet location, hours and maintenance schedules, the Cat App provides alerts for required maintenance and assists with requesting service from the local Cat dealer. Remote Troubleshoot connects the machine to the dealer’s service department via the internet to quickly diagnose fault codes without on-machine cable connection. Additionally, Remote Flash ensures the wheel loaders are operating with the most up-to-date software without impacting the production schedule.

Enhanced cab comfort

The Next Generation loaders got an all-new office as well. The redesigned cab features the following improvements:

Dynamic damper seats slow down travel for a smoother ride than an air cushion alone. Options include heating or heating and ventilation for year-round comfort.Sound suppression, seals and viscous mounts decrease noise levels for a quieter work environment.Seat-mounted electrohydraulic joystick steering reduces operator fatigue and provides better visibility than a steering wheel. (Bonus, this switch adds two more inches of legroom than the previous series. An HMU steering wheel is available as an option for the 966 and 972 powershift models.)A new dashboard and high-resolution touchscreen display provide intuitive and user-friendly loader controls.Application profiles set multiple machine parameters with the press of a button and can save more than 40 different operator settings.A wide door that unlocks remotely from the ground plus incline steps eases cab entry and exit.

Choosing the right wheel loader for your operation

So, which medium wheel loader should contractors choose for their needs? Other key differences between the models include engine horsepower, counterweight size and linkage. (See our quick specs below for more details.)

Available in capacities ranging from 3.75 to 18.25 cubic yards for the new 966 and 972 loader series, Cat Performance Series buckets balance shape against the machine’s linkage for higher fill factors and better material retention than other designs with the same rated capacity. Fusion Quick Coupler buckets enable rapid tool changes without leaving the cab, so the loaders move quickly from task to task.

The 972 outfitted with a 7-cubic-yard bucket will move 15-17 percent more material than a 966 outfitted with a 6-cubic-yard bucket. “[The 972] would be more of a three-pass loader, whereas the 966, depending on the trucks that you’re loading, might be more in that four-pass range. That’s a whole extra pass,” says Schmidtgall. “You’ve got to determine, do my production requirements demand a larger machine or is a smaller machine going to be adequate?”

In addition, special purpose-built options for the loaders include a configuration that offers higher payload capability for loose-aggregate-handling applications. Industrial and waste models feature the guarding and reinforcement required for working at transfer stations, recycling facilities, scrap yards and demolition sites. For demanding applications like steel mills and slag handling, the loaders can be ordered in the steel mill configuration that incorporates additional levels of safety.

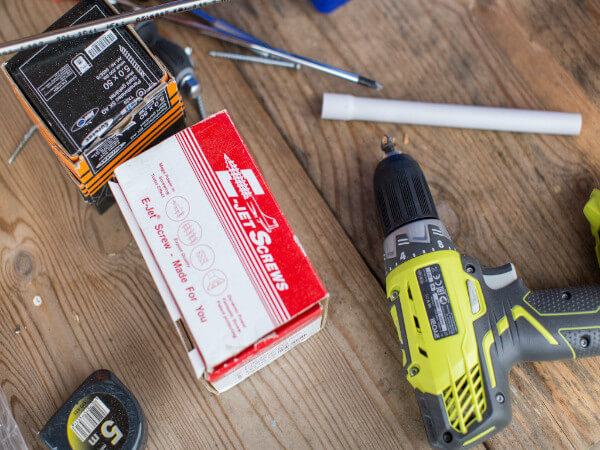

Quick specs

Caterpillar 966, 966 XE, 972, 972 XE wheel loader product specifications.Caterpillar; Graphic: Equipment World

Did you miss our previous article…

https://constructionosa.org/?p=871

“We All Just Worked Our Guts Out”: Contractor Pulls in $1.7M in First Year

Bill Panunzio was employed by a construction firm and looking for his chance.

“I was running their jobs and thought, ‘If these guys can do it, why can’t I?’” Panunzio says. “So at 49 years old, I started all over again.”

Industry veterans Curtis Collard and Ryan Greenwood were also looking for new opportunities. Collard had been running FP Asphalt & Crack Sealing and Greenwood was running his sealcoating division. The three got together and formed Preferred Paving in 1997.

Wes Turner, project manager and estimator for the company, had joined Collard’s business before Preferred was formed. “At that time, we did primarily crack sealing and small patching,” Turner says. “When Bill came, we bought the paver and got after it.”

Combined they have more than 100 years of construction experience, and that showed in their results. The first year, the company had $1.7 million in revenues doing a combination of commercial and residential asphalt work.

“We all just worked our guts out,” Panunzio says bluntly.

Between them, Ryan Greenwood, Bill Panunzio and Curtis Collard (l. to r.) offer more than 100 years of construction experience.Preferred PavingPreferred Paving now has revenues between $10 million and $13 million, around 40 employees and specializes in commercial grading, site excavation, asphalt paving and maintenance.

“We have the luxury to choose to do the jobs we want to do and do them right,” Panunzio says. In fact, the company motto is “don’t just do it – do it the best.”

Preferred Paving at the High West Distillery.Equipment WorldAll three take a hands-on approach to the business. They have served various roles throughout their time together – basically whatever needs to be done.

Collard now serves as an estimator, project manager and oversees safety. Safety is an integral part of the tight weave that makes Preferred Paving’s jobs run smoothly.

Click here to enter this year’s Contractor of the Year contest. Hurry! The deadline for nominations is Nov. 19th.

Suzanna Allen, who has been with Preferred for more than 20 years, runs the company’s sealcoating division, which provides a variety of repair services. “She’s awesome,” Oredson says. “And at their core, the whole team is about doing things right. They’ve got a good transition team to perpetuate the company going forward.”

In the early days, the company created an accounting system that serves them today. After a general contractor required them to go through complicated invoicing hoops that delayed payment, Preferred Paving developed a work order system that included the job and invoice numbers that the GC signed on the spot.

“The way we do business is really simple,” Collard says. “Our work order is also our invoice number. We have a low percentage of uncollected invoices.”

Core and a spare

Preferred has a fleet of pavers, graders, excavators and rollers.

“The Cat 555-size pavers work out perfect for us because you do both big and small custom jobs,” Greenwood says. The company has four pavers, which usually translates to three out on jobs and one spare. “That spare has really helped us,” Panunzio says.

The Cat 120 grader is also a good fit. “It’s just versatile,” Greenwood says. “You can do both a subdivision with it and a custom driveway.” Same with utility rollers that can be pulled with a pickup and transported anywhere.

“Very rarely is our equipment in our yard,” Panunzio says.

Heated driveways

Residential and commercial customers are now starting to request heated driveways. “They get so much snow up in areas like Park City, and they don’t want to shovel their driveways,” Turner says. “We’re paving asphalt over heat tubeing, and we’re one of the few companies in Utah that will do that.”

This work requires digging down around 10 inches and putting down the road base. Preferred then hires a firm to place the heat tubing that runs a mixture of heated water and antifreeze in a closed-loop system. The sub then connects it to a boiler located in a house or building and pressurizes the system.

Preferred Paving then comes back in, places sand around and above the piping, a job that requires hand placement. “You rake it out by hand, then you can water it and roll it,” Turner says. “At that point, you can put a paver and truck on it, but you can’t turn. You really have to pick your angle and then go straight out and pick another angle.”

Utah homeowners like that, even in a snowstorm, they’ll have a wet driveway with no accumulation.

dvice for those getting into construction

Equipment World

Collard warns contractors not to get too excited about their first big profit on a job. “Don’t make $10,000 and then buy a boat, jet skis and four wheelers,” he says. “If the next two jobs are losers, you’re trying to figure out how to pay for materials. Wait to buy the toys and make sure you have a good accounting system.”

“And don’t do it unless you have access to good people because people are everything,” Collard emphasizes. “You can buy all the equipment in the world, but if you don’t have good people, you won’t go far. If you don’t have experience, you must have people who have experience.”

“They are outstanding professionals,” says client Andrew Carlino with CR England. “They treat people like people and not like numbers, and they’re quick to get a job done. Everybody works hard and everyone works together as a team. In fact, I wish I could load them up and take them with me to the other states I cover.”

“We have plenty of options in the valley with paving contractors, and the fact that we use them almost exclusively speaks volumes,” says Tony Treasure with Noland & Son. “They do excellent work. They know it’s about more than being a contractor; it’s about being a craftsman and truly being bought in to the quality of work you’re putting out.”

Did you miss our previous article…

https://constructionosa.org/?p=836

Ditch the Shovels with the Mud Dog 700 Vacuum Excavator

For contractors who want to prevent underground utility strikes but don’t need big equipment, Super Products is rolling out its new Mud Dog 700 vacuum excavator.

The company equipped the Mud Dog 700 for working in tight, small spaces without sacrificing payload, with its 7-cubic-yard debris body and a 600-gallon water tank. It’s also much safer and faster than using shovels, the company says.

The vacuum excavator can dump at up to a 50-degree angle and into a 48-inch container. It has a low overhead height and center of gravity. The dump body also has an electric vibrator to shake material out of the bed and an auto-deploying tailgate.

The Mud Dog 700 vacuum excavator features a 7-cubic-yard debris body and a 600-gallon water tank.Equipment WorldThe boom can extend to 18 feet and rotates 270 degrees. At 8 inches in diameter, it is mounted to the rear of the truck. It can tilt 10 degrees.

The Mud Dog 700 comes standard as a hydro excavator but can be equipped with an air excavation package. It can be operated by wireless or wired remote control.

The water system pumps up to 11 gallons per minute at 3,000 psi. The vacuum system produces 3,100 cubic feet per minute of suction. A 3,700 cfm vacuum pump is an available option.

Other options include a scale system, grounding system, a debris body level sensor, a toolbox and safety cameras that give a 360-degree view around the truck. A variety of truck chassis configurations are available in either manual or automatic transmission. The Mud Dog 700 displayed at the Utility Expo in September was mounted to a Peterbilt tandem-axle truck.

A 4,000 BTU water heater is also available with heated lines for working in freezing temperatures.

The Mud Dog 700 vacuum excavator from Super Products is designed to be compact yet powerful for smaller jobs.Equipment World

Reconstruction of First I-40 in N.C. Wins Top National Award

A $102 million reconstruction of the first section of Interstate 40 built in North Carolina has won a top national transportation award.

The I-40 section was built in 1958 and has been reconstructed into a 1.2-mile gateway to Winston-Salem. It was recently named the Grand Prize winner in the 2021 America’s Transportation Awards. The honor is sponsored by the American Association of State Highway and Transportation Officials, AAA and the U.S. Chamber of Commerce.

The roadway had been known as I-40 Business, but in February 2020, it opened as the new Salem Parkway – six months ahead of schedule, according to the N.C. Department of Transportation. The contractors were able to achieve the faster schedule after a decision was made to close both lanes of traffic on the highway – a first for the state.

“This has been an unprecedented feat,” said NCDOT Division 9 Engineer Pat Ivey at the time of the parkway’s opening. “Never in the history of our state has a section of freeway been closed in both directions at the same time for reconstruction.”

One of two new pedestrian bridges over the reconstructed Salem Parkway in Winston-Salem, North Carolina.NCDOTIt was estimated the project would have taken six years without the complete closure. Instead, it was completed within two years.

The contractor was a joint venture of Flatiron Constructors and Blythe Development. It hired 41 contractors and subcontractors, involving about 600 workers, according to NCDOT.

The project consisted of 10 bridge replacements, two new pedestrian bridges, a walking and biking path and extended sidewalks, as well as aesthetic improvements. Other improvements included pavement rehabilitation, safety upgrades and reconstructed shoulders and ramps.

People’s Choice Award

The Kansas Department of Transportation’s project to revamp an old Kansas City interchange that had been a dangerous eyesore won the People’s Choice Award, which is based on online voting.

The Turner Diagonal Interchange was built in the 1960s and was supposed to have toll booths, but they were never installed. That left miles of “obsolete and hazardous ramps, cutting off land prime for development,” according to AASHTO.

The $30 million KDOT project redesigned the interchange to make it safer, reduce traffic congestion and improve access to public transit. It also boosted the local economy by improving access to area businesses and created thousands of jobs, AASHTO says.

The reconstruction of the Turner Diagonal interchange in Kansas City, Kansas, won the People’s Choice Award in the America’s Transportation Awards competition.Kansas DOTThe NCDOT and KDOT each won $10,000 to be donated to a charity or transportation-related scholarship program of their choice. They were chosen among a field of 80 nominations and 25 state DOTs.

For more details about the award, click here.

Toolbx Delivers Materials, Supplies Within 2 Hours

Contractors, foremen and most construction workers know what happens when a crew comes up short of materials, tools or supplies on a jobsite. Suddenly, you have a bunch of high-skilled, high-wage people standing around with nothing to do.

That’s the problem Erik Bornstein, CEO of Toolbx, set out to solve four years ago. Bornstein spent 15 years in the construction industry building a successful company in the custom home and commercial building markets and saw the knock-on effects of supply and material interruptions first-hand. Additionally, he felt the normal process of securing supplies and materials seemed riddled with slow-downs, uncertainties and inefficiencies.

The new company he founded, Toolbx, is aimed squarely at solving these inefficiencies with an app that allows users to order almost any type of material or supplies and have them delivered, if need be, within two hours.

“I saw a huge lack of technology available specifically for procurement of construction materials,” says Bornstein. “And yet 50% of the budget for any project is for materials – whether it be a small remodel, a medium size home, or a large commercial building.”

Bornstein identified three basic problems in the construction materials acquisition process:

One: guys leaving the job site, to go pick up materials, multiple times a week.

Two: the lack of digitization around sourcing. A project manager, owner or a site super had to call or email a bunch of different suppliers, just to see what’s available, eating up more valuable jobsite time.

Three: the payment and approval process. “Most builders have 10 to 20 different supplier accounts,” says Bornstein. “It was an accounting nightmare for us.”

The vision for Toolbx was to take all three of these pain points and create a digital materials procurement platform that connects builders with their suppliers. “We do it in a transparent, digital way to give time back to the builder by making it fast and easy,” says Bornstein.

Supply chain visibility

The key was to provide visibility. “When you order from a traditional supplier you don’t know where the materials are, you don’t know when they’re going to show up and you often don’t get a confirmation when they ship,” says Bornstein. “If you’re a builder working on multiple jobsites, not having that visibility can cause a lot of friction.”

For a Toolbx user, all decisions get documented and streamlined within the app. You can add jobsites and add crew members with a few taps on a smartphone. Every order is GPS tracked. And you can place an order 24/7 from anywhere to get the materials to your jobsite anytime between 7 a.m. to 5 p.m. Payment is handled within the app and all your invoices are posted online for you, organized by jobsite.

Delivery within hours

The supplies and materials Toolbx sources run the gamut from hand and power tools to PVC pipe fittings and hardware to rebar, lumber, steel and concrete. “We have about 50,000 SKUs in our database today,” says Bornstein. “But as we go into new markets, we bring on more suppliers and continuously update those SKUs.”

Toolbx outsources its fleet of delivery vehicles and partners with Onfleet, a provider of last mile delivery management software to connect businesses, dispatchers, drivers and deliveries to end customers in real time.

Lumber, drywall, insulation, fencing, decking products and hardware are some of the most frequently ordered items on Toolbx. “The larger orders typically get scheduled well in advance,” says Bornstein.

For large orders, Toolbx will partner with different suppliers and connect the order to their system, so the builder knows they have this material coming from a specific supplier. Then it facilitates the direct delivery from the supplier, and it all gets tracked in the Toolbx app.

“In the markets that we operate in, we can do deliveries in two hours or less,” says Bornstein. “You can schedule your orders in one-hour time slots, but you also have the option to do four- hour or next-day time slots scheduled in advance. You can also place an order at 11 p.m. and have it show up at 8 a.m. the next day.”

marketplace for material suppliers

Toolbx doesn’t stock materials or products. It’s not a threat to retailers. Rather it partners with both big box stores and local specialty suppliers.

“The nice thing about it is that it is a symbiotic relationship,” says Bornstein. “We are driving revenue to them and helping those suppliers digitize as well. We’re not just building tools for the contractor, but we’re also building tools to help optimize suppliers, as well, because it works hand in hand. We’re trying to provide efficiency and productivity to both sides of the equation.”

The company does not charge users a platform fee, but rather adds a markup on items purchased through the app. There is also a delivery fee depending on distance and weight.

Contractors can also get a $99 monthly subscription that offers unlimited, free same-day deliveries and discounts on delivery upgrades and Pro pricing which gives subscription users up to 7% off on materials in the Toolbx catalog. Competitive delivery quotes are also available on bulk orders.

It says it also save customers money on bulk orders. Users who have a large order can send their materials list directly and they will get a competitive quote (using supplier partnerships) including delivery within 24 hours.

Toolbx is available now throughout Canada and is planning a rollout in the United States next year.

Did you miss our previous article…

https://constructionosa.org/?p=709

Improve Excavation Efficiency 45% with Volvo/Topcon Precise Excavator Control

In the first stages of GPS-driven machine control, this technology enabled many contractors to park their motor graders and finish grade with a dozer. As GPS machine control migrated to excavators some even found it possible to finish grade complex contours with their digging machines.

Now Topcon and Volvo have taken steps to further enhance the precision and versatility of excavator machine control by combining Volvo Active Control on the Dig Assist with Topcon’s 3D-MC software on applicable Volvo excavators. And it’s all factory-installed and supported by Volvo dealers.

With the integration, Volvo Active Control automates the digging process and Topcon’s software syncs with the Volvo menus, allowing operators to customize how they want their automatic controls to function. The combined technologies make it easy to dig straight, perfectly on-grade trenches or carve complex elevations, shapes and contours automatically. The GPS-guided bucket stops when it reaches the designed grade, so you move the dirt only once and you never over dig and thus never have to recompact or regrade using an additional machine. According to Volvo, these features can improve excavation efficiency by as much as 45%.

Recent updates to Topcon’s 3D-MC software include over-the-air access to Sitelink3D, support for LandXML files, over-the-air remote support and a new graphical user interface. In addition to being 3D machine control capable, Volvo’s Active Control software supports auto-tilt features for tilt buckets and Steelwrist tiltrotators. It also offers several position limiting features for the bucket and boom such as return-to-dig (bucket recall) and automatic back grading. Volvo’s Boundary Limits package enables operators to automatically stop the swing motion at a set angle to assist in digging and truck loading. It also provides pre-set boom and bucket elevations and swing to avoid side or overhead obstacles.

For customers in North America, the integrated technology is offered on three models, the EC220E, EC250E and EC300E, with additional models to be added to the list in 2022. For customers in Europe, Oceania and Asia, Volvo Active Control is currently available on the Volvo EC220E, EC250E, EC300E and EC350E crawler excavators.

Did you miss our previous article…

https://constructionosa.org/?p=694

Elon Musk’s 29-Mile Vegas Loop Under the Strip Wins Approval (Video)

Elon Musk’s Boring Company has won permit approval and a franchise agreement to build the Vegas Loop under the Las Vegas Strip.

The 29-mile underground transportation system would connect with the Las Vegas Convention Center Loop that opened in June. That .8-mile link transports convention center goers through tunnels in electric Teslas and is Musk’s first fully commercial operational tunnel.

The Vegas Loop would have 51 stations throughout the Strip and into Clark County and would have a capacity of 57,000 passengers per hour. The Clark County Commission approved a special-use permit October 20 for The Boring Company to apply for and receive building permits to build the tunnels, according to the Las Vegas Convention and Visitors Authority.

The commission also approved a franchise agreement with Boring that allows it to operate the Loop. Boring would pay to build the Loop and then collect fares from passengers. The commissions says no tax dollars would go toward funding the project. The franchise agreement also faces a vote by the Las Vegas City Council.

Along with the Strip, the Vegas Loop would connect to downtown, McCarran International Airport and Allegiant Stadium. The Boring Company says the goal is to eventually link Las Vegas and Los Angeles.

A map of the proposed route of the Vegas Loop to be built by Elon Musk’s Boring Company.The Boring CompanyBoring and Las Vegas convention center representatives hailed the Vegas Loop as a relief to the city’s traffic congestion and an easier way to get visitors to their destinations. An example provided by Boring says a trip from the convention center to Mandalay Bay, which can take up to 30 minutes, would be shaved to 3 minutes with the Loop.

“The Vegas Loop will be a game-changer for our visitors in moving them around our exciting destination quickly, conveniently and in an entertaining ‘Only Vegas’ way,” says Steve Hill, LVCVA president and CEO.

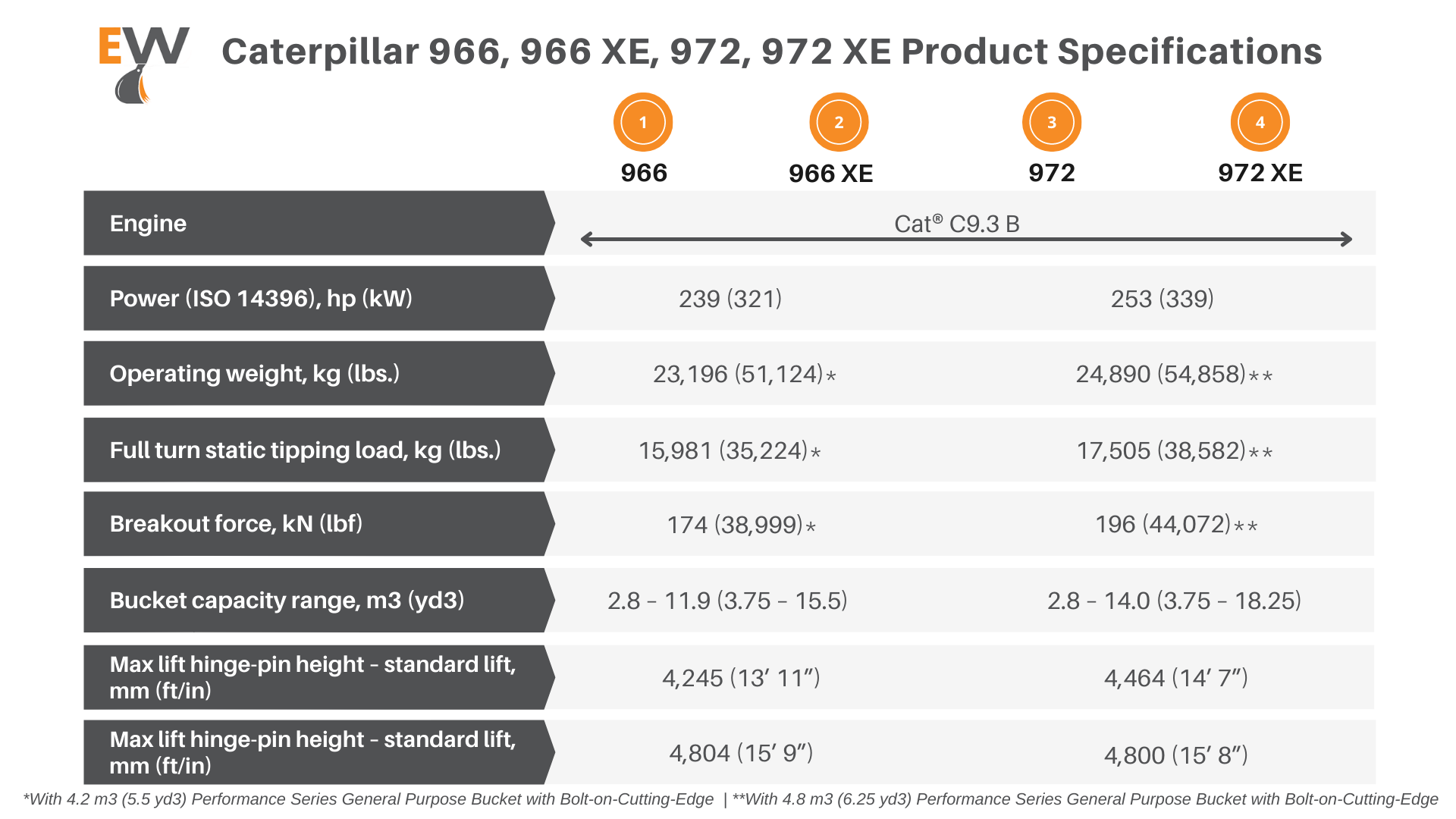

The electric Teslas would travel through the tunnel directly to a passenger’s destination station with no stops along the way, unlike a subway system. The Boring Company provided the following sample trips and fares:

Sample fares for the future Vegas Loop, which would be self-supporting.The Boring Company

Musk envisions the Teslas reaching speeds of up to 150 mph and being autonomously driven. High-occupancy automated electric Teslas are also planned that would hold up to 16 passengers with sitting and standing room.

The convention center Loop, which opened in June, consists of a mix of 62 Tesla Models 3 and X that have drivers and reach top speed of 40 mph, because of the tunnels’ short length. They can hold up to five passengers.

The convention center tunnels are 40 feet underground. Riders can travel across the convention center campus in 2 minutes versus a 25-minute walk. The Loop debuted at World of Concrete this year. It cost $52.5 million to build. It has a capacity of 4,400 passengers per hour and three stations.

Check out this video of the convention center Loop:

CMSBrowserComponents.load({ el: ‘#vue-1635441286480-229’, name: ‘OEmbed’, props: {“mountPoint”:”/__oembed”,”url”:”https://youtu.be/UIP0WQnQyps”,”attrs”:{“type”:”oembed”,”id”:”https://youtu.be/UIP0WQnQyps”,”element”:”aside”}}, hydrate: false });

Did you miss our previous article…

https://constructionosa.org/?p=687

Dig in Tight Spots with Komatsu’s New PC78US-11 Compact Excavator

Komatsu has introduced a new “tight tail swing” excavator well-suited for urban environments, confined spaces and crowded jobsites.

With its 68-horsepower engine, six work modes and swing radius under 5 feet, the PC78US-11 can handle precise digging, as well as large excavation tasks.

The 12-foot 2-inch boom has a greater raising angle and a short implement swing radius (6 feet 9 inches minimum), giving the PC78US-11 the ability to dig efficiently in a crowded space. At the rear, the tail swing radius measures just 4 feet 7 inches. Viewed from above, both the front and the rear corners of the superstructure are rounded, with the maximum cab extension over the tracks at just 9 inches.

For fast digging

Komatsu’s newest tight tail swing excavator is ideal for urban environments and confined spaces.Komatsu

Good operators like a quick machine, and Komastu’s faster boom up and swing speed increases productivity by 9%. To better match machine performance to the application, Komatsu arms the PC78US-11 with six work modes: power, economy, lifting, breaker, attachment-power, and attachment-economy.

For operators who prefer backhoe-style controls, a pattern change selector valve comes standard. The grading blade has a new moldboard profile to improve backfilling and grading efficiency. The PC78US-11 accepts buckets from 0.10 to 0.26 cubic yards.

Low maintenance demands

A new high-output 2.4-liter, Tier 4 Final engine gives you ground-level access to service points. The heavy-duty, high-pressure common rail fuel injection system and cooled exhaust gas recirculation (CEGR) achieve near complete combustion in cylinder to reduce emissions.

A Komatsu diesel oxidation catalyst removes exhaust soot and enables 100% passive regeneration without a diesel particulate filter or regular refills of diesel exhaust fluid. The no-DPF, no-DEF design translates into lower owning and operating costs, reduced maintenance and one less component to replace or worry about.

Komatsu’s compact engine makes room for a fan clutch system, allowing engine and hydraulic system tuning to reduce noise by a full decibel. Typical in-cab noise levels measure 71 decibels — about the same as a household vacuum cleaner. When engine cooling is not required, the viscous fan clutch reduces parasitic horsepower draw. Overall engine improvements boost fuel efficiency as much as 13%.

Cab comfort

The air-suspension seat has deep side supports and an adjustable backrest angle to support operators of all sizes. The cab comes with AM/FM radio with USB and Bluetooth technology.

Komatsu improved cab dampening by incorporating a spring and a longer stroke on the viscous cab mounts. This, plus a beefed up deck, reduces vibration to the operator to keep him or her more comfortable and focused throughout the day. The sealed and pressurized cab keeps dust out and automatically maintains temperatures to the level set on the monitor.

A sliding cab door makes access easier, especially when you’re entering or exiting the excavator up against a wall or in confined spaces. The cab is ROPS certified and satisfies the requirements of ISO OPG Top Guard Level 1 for falling objects.

Crowded jobsites often restrict sight lines, so Komatsu added a 7-inch LCD display to the PC78US-11 with a standard rearview camera image. LED lights provide nighttime illumination of the jobsite.

The variable displacement/axial piston hydraulics for the boom, arm, bucket, swing and travel circuits offer a maximum flow of 44.4 gallons per minute. Relief-valve settings for implement circuits are rated at 4,264 psi. The auxiliary circuits put out 36.5 gpm/3,830 psi (two way) and 21.1 gpm/2,490 psi (one way).

For travel and trailer considerations, the PC78US-11 has an operating weight of 17,747 pounds.

Did you miss our previous article…

https://constructionosa.org/?p=684