Home » Construction Services (Page 6)

Category Archives: Construction Services

Report: One-Fourth of Infrastructure Faces Flood Risk. (Here’s How to Check Your Area’s Threat Level.)

A new report estimates that one-fourth of all critical infrastructure in the U.S. is at risk of flooding, and that percentage will increase as storms become more severe due to climate change.

The science and technology nonprofit First Street Foundation, in what it calls “the first ever nationwide community level flood resilience report,” says state and local governments are not equipped to handle the present and future flood risks to critical infrastructure.

“As we saw following the devastation of Hurricane Ida, our nation’s infrastructure is not built to a standard that protects against the level of flood risk we face today, let alone how those risks will grow over the next 30 years as the climate changes,” says Matthew Eby, founder and executive director of First Street Foundation.

The “Infrastructure on the Brink” report says that 25% of current “critical infrastructure,” such as utilities, airports, ports, and emergency services like police, fire and hospitals, is at risk of becoming inoperable due to flooding.

It estimates these other current infrastructure flood risks:

23% of all road segments in the country (nearly 2 million miles of road). 20% of all commercial properties (919,000).17% of all “social infrastructure” facilities (72,000). This includes such properties as schools and government buildings.14% of all residential properties (12.4 million).

The risks are expected to increase through 2051.

“Over the next 30 years, due to the impacts of climate change, an additional 1.2 million residential properties, 66,000 commercial properties, 63,000 miles of roads, 6,100 pieces of social infrastructure and 2,000 pieces of critical infrastructure will also have flood risk that would render them inoperable, inaccessible or impassable,” the report says.

This chart shows the expected increase in flood risks by infrastructure category over the next 30 years.First Street Foundation’s “Infrastructure on the Brink” report

The report shows these four states facing the highest concentration of current risk: Louisiana, Florida, Kentucky and West Virginia. Of the top-20 at-risk counties in the U.S., 17 are in these four states.

The report also provides data on all at-risk cities and counties, and you can search on First Street’s website to find the flood risk for your property with the nonprofit’s free FloodFactor tool.

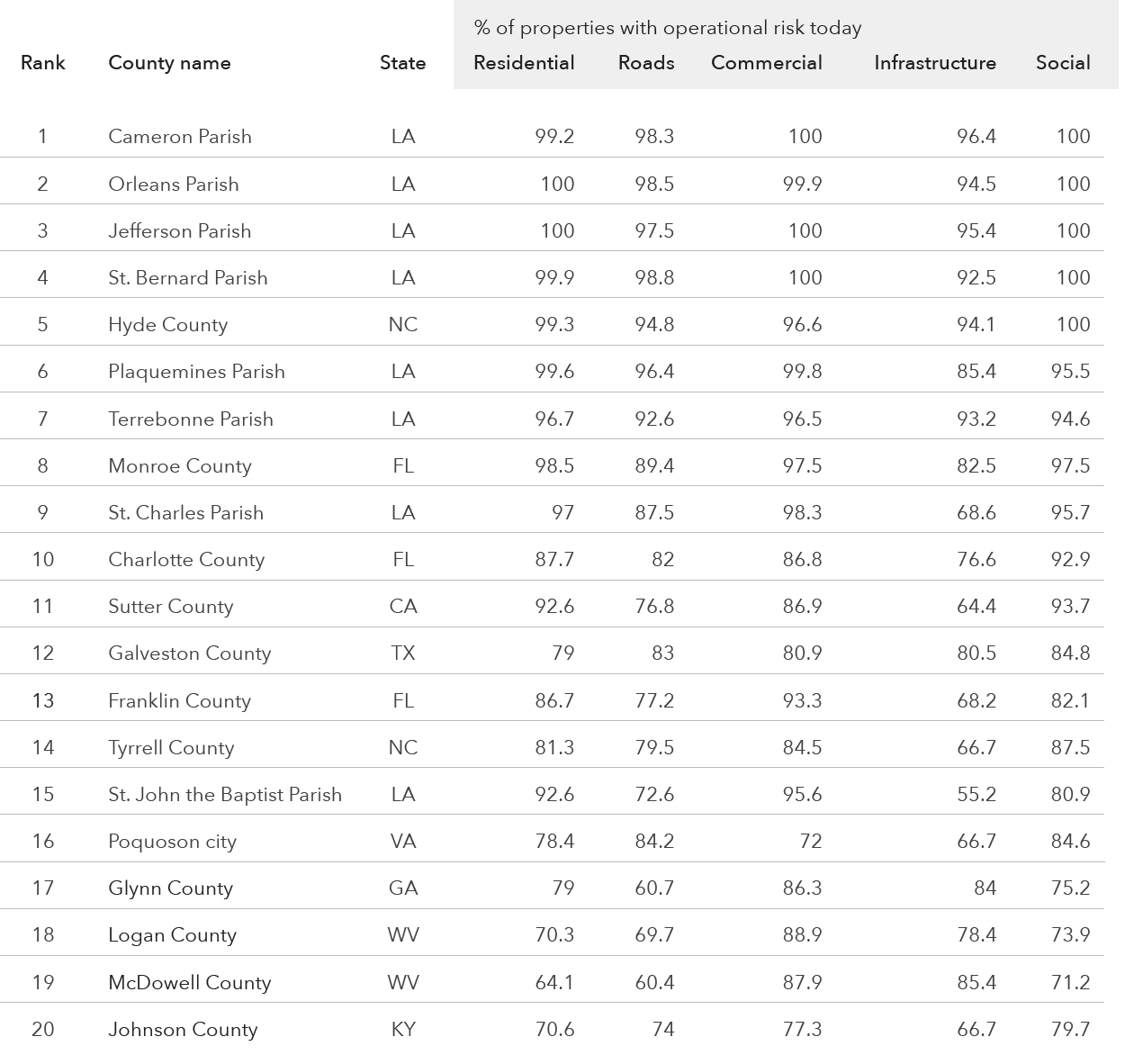

This chart shows the top-20 counties most at-risk to physical infrastructure flooding and the percentages of their infrastructure categories that are at risk. (Note: The “Infrastructure” column represents “critical infrastructure,” such as airports, fire stations, hospitals, police stations, ports, power stations.)First Street Foundation’s “Infrastructure on the Brink” report

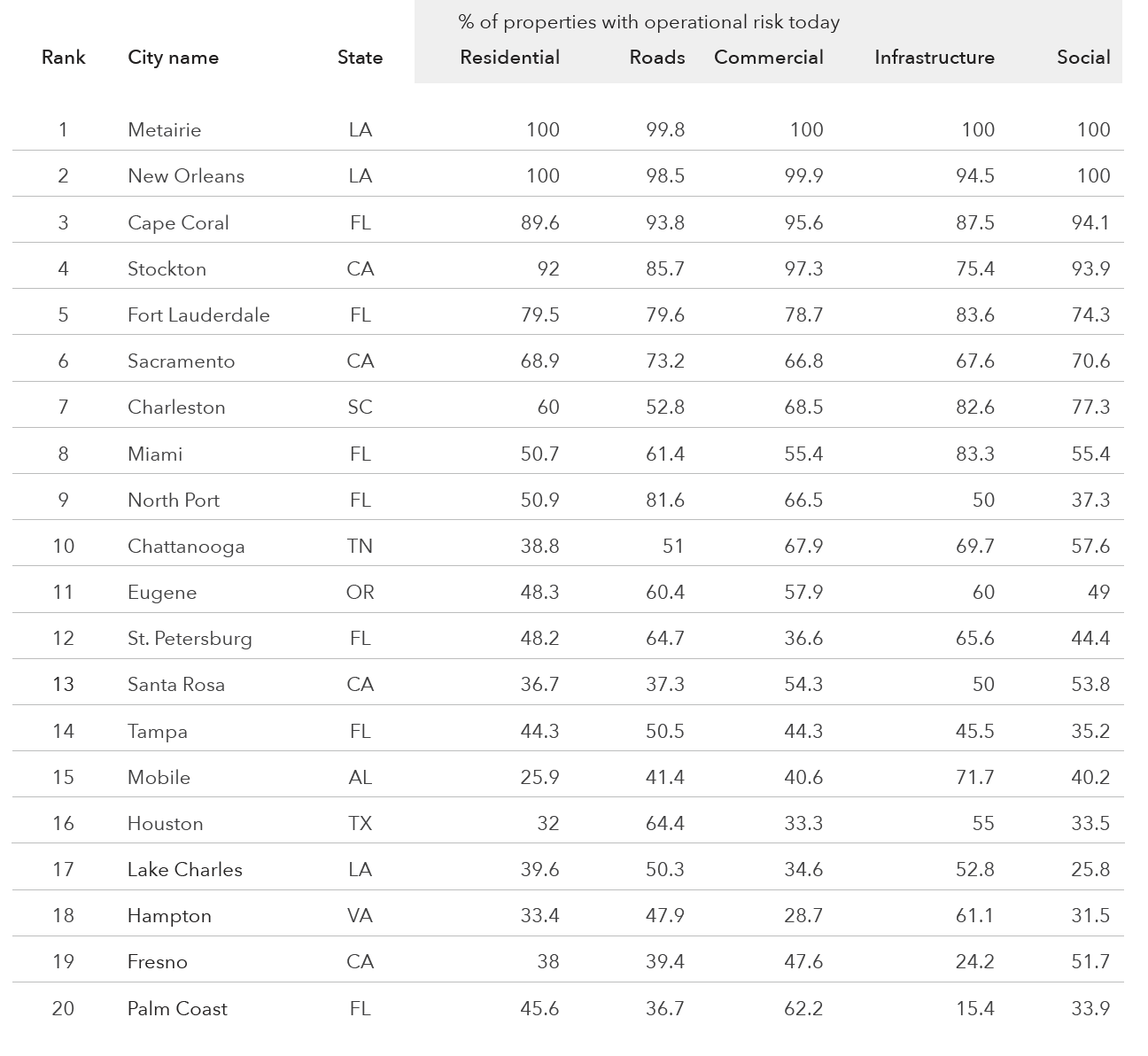

For cities facing the most flood risk today, Moliere and New Orleans, Louisiana, top the rankings, with most, if not all, of their infrastructure vulnerable. Cities in California, South Carolina, Florida and Alabama also made the list.

This chart shows the top-20 cities most at-risk to physical infrastructure flooding and the percentages of their infrastructure categories that are at risk. (Note: The “Infrastructure” column represents “critical infrastructure,” such as airports, fire stations, hospitals, police stations, ports, power stations.)First Street Foundation’s “Infrastructure on the Brink” report

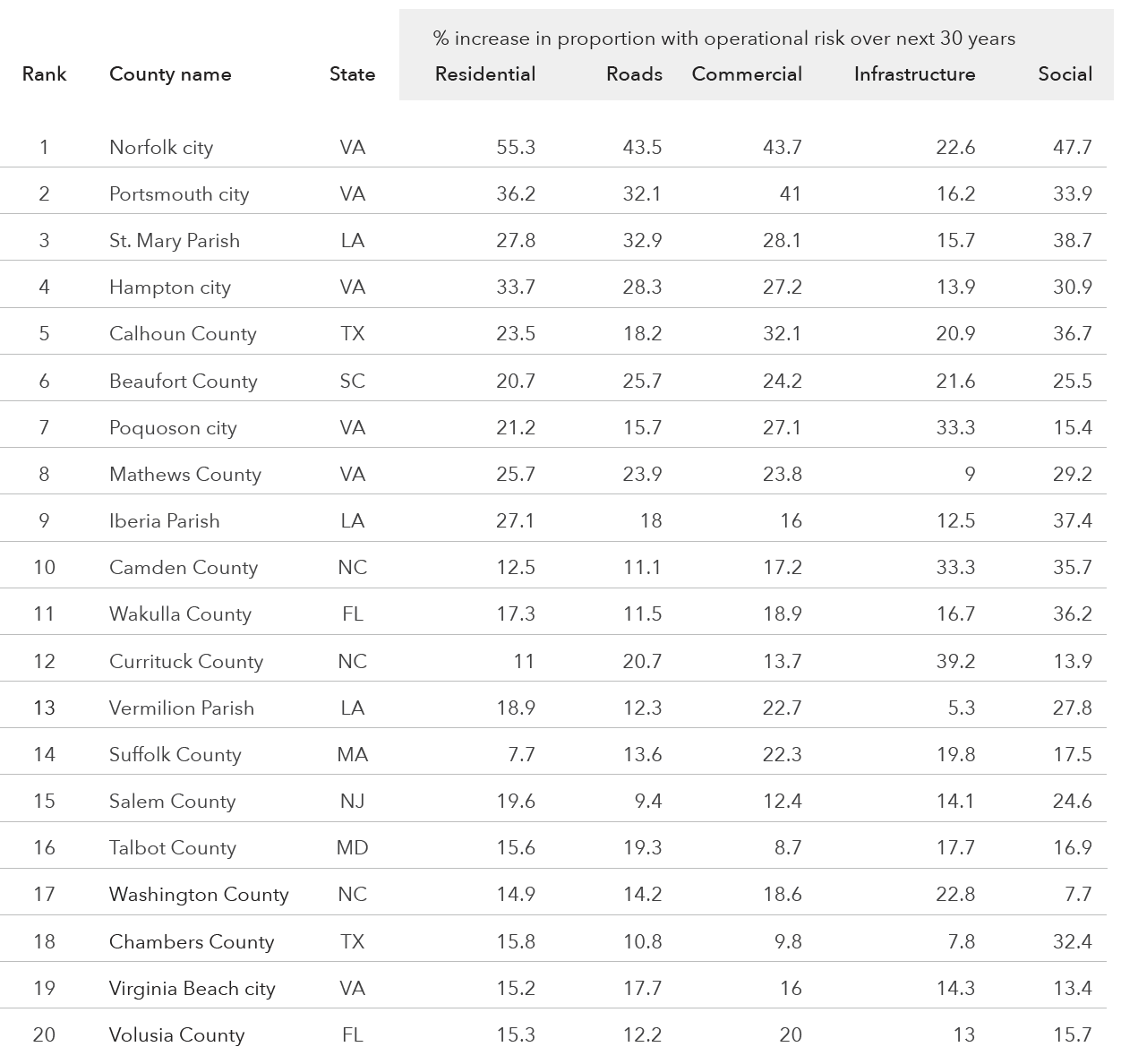

The report also looks into the future, showing which counties will see the largest percentage increase in infrastructure risk by 2051. Virginia has several metro areas facing a significantly increased threat. The list also includes counties in North Carolina, Massachusetts, Maryland and Texas.

This chart shows the top-20 counties with the highest estimated percentage increase of risk to physical infrastructure flooding by 2051 and the percentages of their infrastructure categories that are at risk. (Note: The “Infrastructure” column represents “critical infrastructure,” such as airports, fire stations, hospitals, police stations, ports, power stations.)First Street Foundation’s “Infrastructure on the Brink” report

The report says the impact of the increased risks could devastate local communities. It notes that in Harris County, Texas, home to Houston, 770 hospitals, public utilities and water-treatment plants currently risk becoming inoperable due to flooding this year.

Miami-Dade, Florida, has 1,640 schools, churches and museums at risk. The Chicago metro area has 225,000 residential properties at risk. And in the New Orleans area, 99% of the roads are at risk of becoming undrivable because of flooding, the report says.

First Street Foundation hopes the data will help prioritize funding toward protecting infrastructure from flood risks.

“Our work aims to determine the amount of flooding that would render infrastructure either inoperable or inaccessible,” says Dr. Jeremy Porter of First Street Foundation. “By applying research on depth thresholds and comparing them to flood data and probability metrics, we can determine roughly the extent of flooding that would cause a road to be impassable to cars, or a hospital to be shut down.”

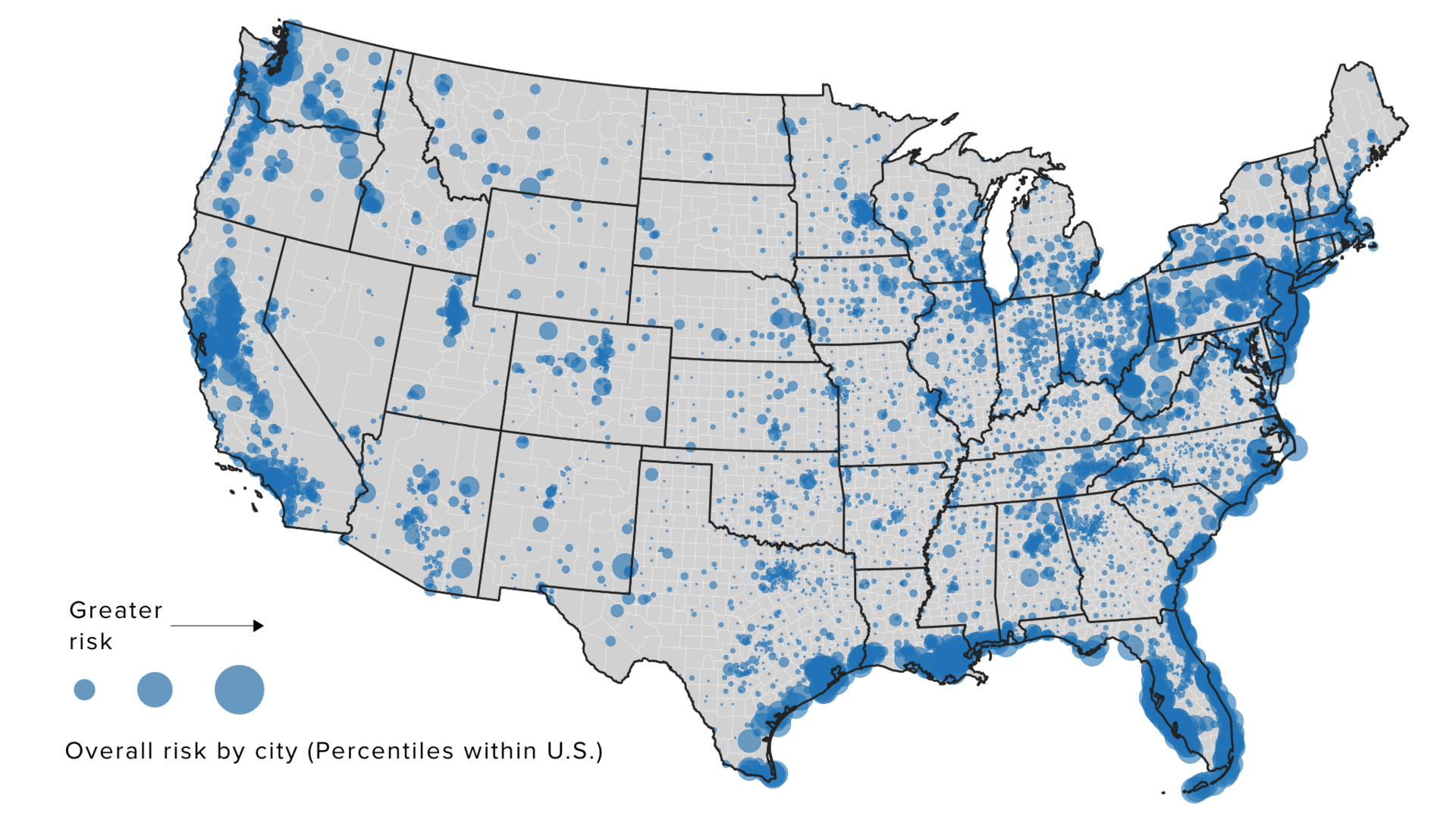

This map shows where the greatest flood risks are to infrastructure.First Street Foundation’s “Infrastructure on the Brink” report

Industry Roundup: H&E Opens 3rd Utah Branch

H&E Equipment Services has opened a new rental branch just north of Salt Lake City in Ogden. It is the company’s third Utah facility.

The 8,500-square-foot facility sits on three acres and features a fenced yard, offices, parts warehouse and separate repair shot with six service bays. The facility will offer construction and general industrial equipment for customers in northern Utah, southeast Idaho and western Wyoming.

Chris Baron, who also leads the company’s Salt Lake City branch, will manage the location.

Kirby-Smith names Kunin VP, adds Atlas

Kirby-Smith Machinery (KSM) has named Mike Kunin vice president of national accounts, following the promotion of John Arapidis to president and CEO.

Kunin will oversee the management and continued development of strategic partnerships between the company and its national account customers. He comes to the dealership after having held several key positions at Komatsu America during the past 21 years, including parts sales, construction and support equipment and most recently as business director of Komatsu’s central region. He will be located in KSM’s headquarters in Oklahoma City.

SMH GroupKMS has also added the SMH Group US’s line of Atlas material handlers and will represented the line in Oklahoma, Kansas, Missouri and Illinois. The Atlas line includes mobile industrial and industrial tracked machines for the scrap, wood and recycling markets, among others.

KMS has 12 branch locations in Oklahoma, Texas, Kansas and Missouri.

W.W. Williams relocates Charleston store

W.W. Williams Company’s Charleston, South Carolina, branch has moved to a new location. The 20,000-square-foot facility has 14 service bays for repairing and servicing medium- and heavy-duty trucks, fleets, construction equipment, emergency vehicles and marine vessels in addition to power generation sales and service.

Maverick Environmental adds Morbark line

Maverick Environmental Equipment has become a Morbark Industrial Products dealer for Ohio, Indiana, Kentucky ad western West Virginia. The company will sell and service Morbark’s line of tree care, forestry, sawmill and wood recycling equipment.

Herc buys Rapid Equipment Rental

Herc Holdings, parent of Herc Rental, has bought Toronto-based Rapid Equipment Rental. Rapid Equipment Rental currently has 110 employees and seven locations. Founded in 2013, it serves the industrial and construction markets in Toronto and the surrounding areas.

Herc says the acquisition supports its long-term strategy to achieve greater density and scale in select urban markets across North America. It currently has 295 locations in North America.

MANUFACTURERS

Bomag adds milling, paving VP

Bomag Americas has named Chris Colwell its vice president of milling and paving, responsible for overseeing the company’s new business unit segment. Colwell’s industry experience includes positions with Astec Industries, Carlson Paving Products and managing a road construction equipment dealership.

Generac expands in Wisconsin

Generac has announced it will invest $53 million in facilities across the state over the next three years, creating more than 700 jobs. Expansion plans include a new administrative and R&D facility in Pewaukee, announced in July. The company’s global headquarters will remain in Waukesha, Wisconsin.

Did you miss our previous article…

https://constructionosa.org/?p=539

Use Infrared Asphalt Repair To Improve The Look And Condition Of Your Public Parking Lots

Potholes can become quite costly when left undetected, and most asphalt repair contractors will tell you that they cannot do anything about potholes that form in your driveway. This is true especially of more minor potholes, which can easily be mistaken for simple holes in the surface of your driveway. On the other hand, several kinds of potholes range from football-sized potholes to tree-trunk-sized potholes. In any case, a pothole can be a severe and expensive problem. The following are some common types of potholes and the common issues that can result from them:

Potholes can become quite costly when left undetected, and most asphalt repair contractors will tell you that they cannot do anything about potholes that form in your driveway. This is true especially of more minor potholes, which can easily be mistaken for simple holes in the surface of your driveway. On the other hand, several kinds of potholes range from football-sized potholes to tree-trunk-sized potholes. In any case, a pothole can be a severe and expensive problem. The following are some common types of potholes and the common issues that can result from them:

Parking lot and driveway repairs. There may be times when the edges of a paved parking lot or driveway collapse, creating large and expensive potholes. Unfortunately, asphalt repairs for this problem are quite costly because the area must first be completely excavated. You can hire professionals to do the job, but if you want to save money and do it yourself, then here are some ideas that you might find helpful. For example, you can fill in the collapsed area with gravel and then create a raised patio that will better protect from rain.

Driveway and parking lot repairs. This is one of the most common types of asphalt repairs, as these areas are usually the most abused on a regular basis. They are also some of the most abused surfaces in the entire world, so it’s no wonder that these two surfaces are among the most common types of problems for asphalt surfaces throughout the country. One way to avoid having to do asphalt repairs on this type of surface is to make sure that the parking lot and driveway have proper drainage.

Sidewalk repairs. This is another common type of asphalt repair job, and it can be quite difficult to find good deals on this kind of job. If you need to have asphalt repair done on your sidewalk, you will most likely have to deal with a very dirty and stained surface. Fortunately, there are several ways that you can protect your sidewalks from this damage, and one of them is to have a walkway sealer applied to the surface. The walkway sealer will help to prevent the buildup of hard water and other materials that can damage your sidewalk.

Parking lot maintenance. If you have an asphalt surface in a public parking lot, you are probably going to need some help with some parking lot maintenance. This is especially true if the lot is very wet and the pavement is not level. There are several ways to protect your asphalt surfaces in these kinds of conditions, including parking lot sealcoating. When you apply a parking lot sealcoating, you will be able to protect the asphalt and keep it looking great, even in the most severe conditions.

Speed Bumps and Other Tools. There are some things that you can use for street repairs that are specific to asphalt issues and that include infrared asphalt repair. You can also look into purchasing tools that can help you with making the repair easier to perform and that can help you save time and money. Whether you are dealing with potholes, cracks, or any other type of surface damage, you should be aware of the tools that are available to you for the job.

Parking lot sealing. You may also want to look into the use of a seal coating for all of your public parking lots. These are products that are designed for use on asphalt pavement, which is something that many people don’t realize. Sealcoating can protect the area from cracks, potholes, and other damage that occurs with time and exposure to moisture, heat, cold, dirt, and chemicals that can damage the pavement over time. If you apply this product to your asphalt repairs on a regular basis, you can easily make sure that your public parking lots stay nice and dry, which can help you avoid the expenses of having to replace the pavement in these areas. These sealcoated asphalt repairs can be applied to potholes and cracks, as well as cracks in the asphalt itself.

Parking lot maintenance. In addition to the regular things that you need to do for basic maintenance, such as oil changes and tire rotations, you may also want to consider asphalt repairs for problems that develop on your public parking lots. For example, if you notice that a divider or other item is becoming loose and starting to fall down, you should know that you need to take care of the problem right away. This can prevent damage to your property, which can be expensive to repair. By taking care of small problems as they arise instead of waiting for them to become larger and more expensive to fix, you can increase your chances of avoiding costly repairs later.

Outdoor Living Space – Tips on How to Choose the Right Deck Builder for Your Needs

A deck-building game, also known as a card or board game, is an interactive card game where a deck (a) is the main gameplay focus. Usually, it is much like traditional collectible card games wherein each player uses a deck they draw from. However, it differs since, in a deck-building game, players are also allowed to construct their decks from card stock and other materials that they can acquire from anywhere, depending on their theme and game theme. Usually, there is a deck workshop at the start of the game, where players can mix and match different kinds of materials that they have gathered. Deck-builders even go so far as to provide designs for players to choose from to create their decks.

One of the most fun parts of playing a deck builder game is getting started. Players usually all start with a random set of cards, and to start the game, they need to choose which suit from a pile of basic cards and place them in the center of the playing area. Then, they get to pick some more basic cards and place them in the outermost area of the play area, and so on, until they have exhausted all the cards that are available to them in the game.

Then, players will use their imagination to come up with creative and interesting decks of cards. Some people make their decks entirely of one kind of material while others might mix and match materials from different styles of decks. Some might even create “mini” decks through the mixing and matching of cards, or the combining of different cards into one deck. In some ways, a deck builder is really easy to start playing with since all you need is a simple deck of cards and a little bit of creativity!

Now, it’s time to actually play a game of magic! The point of a deck builder is not only to show off your own creative and artistic abilities but also to help teach children the basics of playing a good game of cards. For example, a good deck builder will usually teach children how to place their cards onto the playing area, as well as to do simple and quick hand movements while they are picking out cards to place onto their decks. This is very helpful in developing the skills of recognizing basic shapes and picking out specific parts of cards.

There are many different kinds of deck builders out there that can be used by both boys and girls of all ages. If you want a fun, imaginative way to learn how to play the game, then a deck builder can definitely be the solution that you’re looking for. There are many sites online that feature various kinds of deck builders for kids. All it takes is a few moments of research to find the best sites that feature this interesting activity.

Another great advantage of using a deck building kit to learn how to play the game is the availability of instructional videos that feature experts showing you step-by-step how to put together your own decks. In addition, these instructional videos can also usually show you how to choose and play a particular kind of card or suit, as well as tips on choosing a themed deck. Many deck builders can even provide you with some basic instructions and then go on to show you how to put everything together. Most decks will include instructions and videos in various sizes so that even small children can follow along.

Of course, deck builders aren’t just for kids anymore. While it may be more difficult for boys to pick out and put together a nice deck, there are also some specialty builders that cater to girls. Some of these builders are specifically geared towards young girls who want something to do in their spare time other than playing computer games or watching television. These builders can be found on the internet, and you can find everything from building construction sets to Barbie and Disney princess decks.

When you are looking to create a new outdoor living space, the last thing you want is to have a horrible design. This isn’t always the case though, especially when you have an abundance of resources. No matter what type of outdoor decking you decide on, make sure that you choose a professional deck builder that you can trust. Even if you know a little bit about construction, it never hurts to get a little hands-on training. A good deck builder should be able to take care of all of the work so that you can sit back and enjoy your decking, while your friends and family have a great time outdoors.

I-49 Missouri-Arkansas Connector Now Open for 290 Miles

Another link in the planned six-state I-49 has been completed with five miles of roadway opening between the Arkansas and Missouri border.

The project’s completion leaves a 290-mile interstate route from Kansas City, Missouri, to Fort Smith, Arkansas. The last five miles of the connector opened October 1.

The I-49 and I-29 corridor will also eventually pass through Louisiana, Iowa, South Dakota and North Dakota, stretching for 1,600 miles and connecting at I-29 in Kansas City. Plans are to add links to New Orleans area ports.

I-29 extends from Kansas City to Winnipeg, Canada. The eventual goal is to provide an uninterrupted Interstate Trade Corridor from Canada to New Orleans and into Central and South America to the Panama Canal, according to the I-49 International Coalition.

Transportation officials in Arkansas and Missouri say they have been discussing the connector for more than 25 years. Construction has progressed in phases.

Shaking hands, from left, are Arkansas Governor Asa Hutchinson and Missouri Governor Mike Parson at the ribbon cutting for the last section of the I-49 Missouri-Arkansas Connector.Missouri Department of TransportationThe final five miles were built between Pineville, Missouri, where construction ended in 2012, and the Arkansas state line.

The project involved building a four-lane divided highway west of Route 71. Access to the newly designated interstate section is only by interchanges. A new interchange was built at Missouri Route 90 west of Jane. Five bridges were also constructed.

The project’s estimated cost was $70.3 million.

“This high-quality roadway will help promote tourism, business investment and workforce opportunities between our two great states,” said Missouri Governor Mike Parson.

Did you miss our previous article…

https://constructionosa.org/?p=450

JKSSB Recruitment 2021 for Various Posts | 462 Posts | 09-11-2021

JKSSB Recruitment 2021 for Various Posts with 462 Posts vacancies, last date to apply is 09-11-2021, apply soon

The post JKSSB Recruitment 2021 for Various Posts | 462 Posts | 09-11-2021 appeared first on ConstructionPlacements.

Product Roundup: Deere’s 470G LC Excavator Gets SmartGrade

The John Deere 470G LC excavator will now offer a full range of grade management solutions including SmartGrade, SmartGrade-Ready with 2D, 3D Grade Guidance and 2D Grade Guidance.

Factory-installed and calibrated from the dealer, the 3D grade control system automates the position of the bucket as you dig, resulting in accurate dimensioned trenches and contour work. That means you only move the dirt once. You don’t have to compact dirt that has been over-excavated, and in many cases, you can eliminate or greatly reduce the time and work done by finishing machines such as dozers and motor graders.

In addition to SmartGrade technology, the 470G LC model features various precision technologies including Virtual Front, Over-dig Protect, Virtual Ceiling, Virtual Floor, Virtual Swing and Virtual Wall. Upgrade kits for Deere’s SmartGrade technology can be installed onto equipment at later dates to match contractors’ changing needs.

Everything’s going autonomous – even Komatsu’s water truck

Komatsu’s HD785-7 autonomous water truck drives itself and remembers how much water to put down.Komatsu

Komatsu has been field testing an autonomous water truck, based on its proven Autonomous Haulage System (AHS). The technology on the concept HD785-7 truck autonomously controls the truck’s movement and water distribution through the same platform.The company hopes to introduce the HD785-based autonomous water truck in 2022.

Komatsu’s AHS enables the water truck to travel autonomously on a pre-defined haul road and work cooperatively with other autonomous trucks and staffed equipment. The system controls the amount of water dispersed, according to the vehicle speed and haul road incline, and also “remembers” the watering history to avoid overwatering.

Trackunit, ZTR join forces to make telematics data easier to use

Machine data is of little value unless you know what to do with it. In other words, it has to be “actionable.” That’s the idea driving the merger of Trackunit and the Industrial IoT (Internet of Things) division of ZTR. The two companies are uniting to accelerate innovation and drive digital transformation — with collaboration and service at the center of their strategy.

After the transaction closes, the combined entity will help customers collect data and translate it into actionable results that enhance utilization, increase fleet availability, improve safety and reduce equipment loss.

Trackunit is an SaaS-based IoT solution that collects and analyzes machine data in real-time to deliver proactive and predictive information to customers. ZTR develops IoT solutions using telematics that allow companies to remotely monitor and manage mobile as well as fixed assets.

In making the announcement, company executives noted that the realm of IoT and telematics has evolved from simple track and trace technology into actionable insights that create value.

“We see the industry at a pivotal turning point when it comes to digitalization of their business and equipment, and customers are looking for a trusted partner,” says Soeren Brogaard, CEO of Trackunit. “By combining our businesses, we’re elevating our technology and increasing the value customers will be able to extract from their data.”

Did you miss our previous article…

https://constructionosa.org/?p=431

How Artificial Intelligence Can Keep Your Workers Safe, Reduce Insurance Costs

Increasing amounts of digital data are being collected on construction sites. Analyzing that information can help contractors understand and predict risk in project delivery – one of the largest risk factors being safety.

Fatality and total incident rates in the construction industry have plateaued for the last 10 years, but a partnership between Newmetrix and StructionSite aims to improve those rates using artificial intelligence (AI).

Newmetrix is a construction technology company that uses AI and advanced analytics to reduce safety risk. StructionSite is a photo and video site documentation app that enables contractors to track project progress. The integration allows StructionSite users to get enhanced data from the 360 jobsite videos and images they are already collecting on the app.

Newmetrix’s platform automatically pulls image and video data from StructionSite. The platform’s AI, “Vinnie,” then analyzes the images to identify more than 100 safety risks, such as work at height, housekeeping, improper ergonomics.

Using predictive analytics, Vinnie combines the image data with other project data to determine the level of safety risk for each project and predicts which 20% of the projects will be responsible for 80% of the risk. Construction companies can use this data to focus their safety efforts on the projects where they will have the most impact.

“Newmetrix has been analyzing StructionSite images from our projects for 18 months,” said Takashi Tsuchiya, deputy section manager at Obayashi Construction. “So far the Safety AI has generated over 1.2 million tags that our safety and project teams can use as opportunities for conversation. As a specific example, over 9,500 examples of housekeeping and 4,500 examples of standing water were identified by the Safety AI. This increases the number of relevant conversations we can have about safety and helps prioritize the teams’ actions. The integration boosts the number of images to generate more tags.”

By integrating Newmetrix and StructionSite, construction companies can:

Use the visual documentation that’s already being collected to create opportunities for safety engagement and to predict safety risksPrevent safety issues before they ariseProtect profitability with lower recordable incident rates and fewer claimsUse a predictive-based safety program to negotiate a better insurance rate

Figuring out what to do with the vast amounts of incoming data from construction sites can be overwhelming, but technology can help contractors make better decisions faster and prevent incidents before they occur.

Did you miss our previous article…

https://constructionosa.org/?p=425

Dozers Decked Out with Tech: Pushing Dirt is Getting Easier

The market is full of new dozers and those new dozers are full of new technology.

The new tech includes increased automation features to make the machines easier to operate.

“One of the biggest struggles facing contractors today is finding and retaining skilled operators,” says Matt Goedert, solutions marketing manager, John Deere. “John Deere is developing several features to help overcome this challenge.”

Manufacturers have also focused on improved design to make their dozers quieter, more comfortable and with increased operator visibility.

Cat improved forward visibility up to 30% on its newest model, the D4. Visibility is especially improved to the top of the blade and the area in front of it. The company lowered the hood line and relocated components that could impede sight.

“The D4 is the smallest of Cat’s mid-size dozers,” says Sam Meeker, market professional, Cat. “Visibility is especially important in applications where this size class is typically found, where obstacles and workers are common on site.”

Here’s a look at the latest dozers and their new technology and design features:

New and improved

The D4 started last year as a rebadged D6K. This was done to align the machine with Cat’s revised machine model naming protocol and to fill a numeric gap in D Series dozers.

The current D4, however, is truly a new machine and has been available since the second quarter of this year.

The Cat D4 is powered by a Cat C4.4 engine rated at 130 net horsepower. Operating weight is 29,259 pounds in non-LGP with 22-inch shoes, and 30,882 pounds in LGP with 30-inch shoes. Blade capacities are 4.26 cubic yards non-LGP and 4.98 cubic yards LGP. Foldable blades are available for both and have the same capacities as the standard VPAT blades.CaterpillarThe rearview camera is integrated into the new 10-inch color touchscreen. The view can be on only during reverse travel or can be left on all the time. In the latter case, the camera view occupies about one-fourth of the screen and is surrounded by operating data. All Next Gen Cat dozers share the same screen layout to help with familiarity.

The D4 has all the machine control options Cat offers on its dozers, including Cat Grade with 3D and the ability to install systems from Topcon, Trimble and Leica. A Waste package includes guarded rear lights, double-skinned fuel and hydraulic tanks, final drive guard and air pre-cleaner.

The HD package is ideal for forestry, demolition and other high-demand applications. It has additional underbelly guards; additional sweeps, sealing and screening to keep out dust and debris; a reversing fan and heavy-duty fenders. Standard and low ground pressure (LGP) versions are available.

A variable pitch angle tilt (VPAT) blade is standard. Blade options include power pitch for more aggressive cutting, and folding blades that bring the blade within the width of the tracks (under 93.3 inches for standard pitch and under 110.8 inches for LGP).

Liebherr offers six models of Generation 8 dozers, from the PR 716 G8 (132 horsepower, 29,231 pounds, 3.82-cubic-yard blade) to the PR 766 G8 (422 horsepower, 119,784 pounds, 22.23-cubic-yard blade). Available operator assist features include Free Grade blade stabilization, Definition Grade for 2D grading, and 3D Grade from Topcon for modeling complex terrain.Liebherr

Liebherr offers Generation 8 models of six dozers, from the 132-horsepower PR 716 G8 to the 422-horsepower PR 766 G8.

The five small and mid-size models come standard with 1D and 2D Liebherr Operator Assist Systems. 1D provides active blade stabilization for free grading; 2D provides active blade positioning for grading to longitudinal and cross slope specs.

3D Grade is an available option and has roof-mounted Topcon 3D Machine Control for complex 3D models. Ready kits, consisting of mounting and cabling, are available for customers using Trimble or Leica systems.

The large PR 766 G8 features Liebherr’s Delta High Drive as well as an oscillating idler and double bogie suspension for improved traction and comfort in mining and other production applications.

Liebherr Silent Design resulted in the company’s quietest dozers, thanks to noise-attenuating changes in cab mounting, hydraulics and drive systems on Generation 8 models.

Electronic pilot controls on the small- and mid-size models allow the operator to tailor response and speed of front and rear equipment and includes blade shake, rear ripper parking positioning and automatic blade lifting when reversing.

The LiDAT on Liebherr Generation 8 dozers has more sensors and greater data management capacity, helping ensure compatibility with current and future site management systems. All G8 models use common-rail diesel engines designed and built by Liebherr.

The John Deere 750L has a Deere PowerTech PVS 6068 engine rated at 131 net horsepower. Operating weight is 38,330 pounds. Blade capacity is 5.6 cubic yards. The dozer has hydrostatic drive with triple reduction final drive. The standard track has 40 shoes with a 7.5-inch pitch and single grousers designed for moderate service. Standard blade width is 129 inches; a 161-inch wide blade is optional.John Deere

Released in mid-2020, the 700L and 750L expand the L Series catalog for John Deere. The first was the 850L, released in 2019.

Features of the L Series include larger, more comfortable operator stations. Noise has been reduced more than half in the 700L compared to the 700K. Heated and ventilated premium seating and automatic temperature control are optional.

Horsepower and operating weight have been increased. An optional 161-inch blade is now available for the 750L. Hydraulic hose and electrical harness routing has been improved to reduce potential rub points, and hydraulic hose length on the 700L and 750L has been reduced 20%.

Komatsu’s D71PXiKomatsu

The D71-24 is Komatsu’s newest dozer. It is available with or without the company’s new iMC 2.0 intelligent Machine Control. All are powered by Komatsu SAA6D114E-6 engines rated at 237 net horsepower.

The D71 is Komatsu’s largest hydrostatic-drive dozer. Track options include 24-, 30- and 36-inch widths with blade capacities of 5.8 to 6.1 cubic yards.

“The D71 was a clean-sheet design,” says Andrew Earing, senior product manager, Komatsu. “The hydrostatic drive and standard PAT blade of the D71 make it a very nimble and versatile dozer.”

Other standard features include heated and ventilated seating, LED work lights and three-speed blade drop to shed sticky materials. Fast steering mode slows the inside track but also accelerates the outside track for tighter, faster turns while still allowing counter-rotation.

In a previous interview with Equipment World, LiuGong indicated its revamped Dressta dozers were scheduled for a fall launch. We have no additional information at this time.

Grade control technology

Deere has launched Slope Control on several dozer models in recent years, filling a need for less complex technology that doesn’t use a 3D model or external reference, such as a base station or laser.

“While adoption of 3D grade control systems has been significant over the past five or more years,” says Goedert. “There is still a place for entry-level grade control technology to grow adoption and simplify tasks.”

Slope Control automatically controls the blade, is designed to be simple to use and offers two operating modes, joystick and target. This entry-level system can be upgraded to Deere SmartGrade advanced 3D grade control at any time. SmartGrade performance responds to multiple inputs, including load levels, material types and dozing activities.

Case factory-fit machine control from Leica is available on 750M through 2050M dozers. Multiple levels of control are also available. For customers with six-way (PAT) blades working in extreme conditions, the iCON grade MCP80SP adds SP sensor technology and dual blade-mounted GNSS antennas for speed and accuracy.Case CE

Case announced in March the availability of its factory-fit machine control option on 750M through 2050M dozers. Packages include Leica Co-Pilot, 2D and dual-mast 3D systems. The factory installation includes calibration using Case World Class Manufacturing processes so the dozer arrives at the dealership ready for immediate use.

Jeremy Dulak, product manager for dozers, cites several advantages to the factory-fit approach. “The first is simplified ordering. Working with your Case dealer, you can group the Leica system that best fits your operation in with the purchase of the machine.” This allows a single payment, a single financing package, a single approval and a single interest rate.

Factory fit also ensures that when the machine arrives at the dealer, “it’s ready to go after just a very quick calibration.” And factory fit preserves residual value, he adds, because “the second owner will have confidence knowing the system was purpose-built to that specific machine and meets all quality and performance standards intended by the manufacturer.”

Komatsu’s iMC 2.0 offers “grass-to-grade automation,” says Earing. Most systems focus on grading; iMC 2.0 adds automated lift control for the fill process. This dramatically aids compaction and reduces the likelihood of costly rework by allowing each layer to be compacted before the next layer is lain.

Komatsu says iMC 2.0 brings performance to a level that is 96% equivalent to that of an experienced operator, which elevates the performance of lesser-skilled operators. Seasoned operators also benefit from iMC 2.0 because it will maintain settings they create, a feature Komatsu calls “operator-guided automation.”

Each Komatsu dealership has a technical service expert to help train customers on iMC 2.0. TSEs also help with the installation of systems from Topcon, Trimble and Leica.

Did you miss our previous article…

https://constructionosa.org/?p=418

Environmentally Friendly Tips to Consider When Moving To a New Home

Moving to a new home is an exciting process. However, the one thing that most people don’t think about is the environmental impact of moving.

The post Environmentally Friendly Tips to Consider When Moving To a New Home appeared first on ConstructionPlacements.

Did you miss our previous article…

https://constructionosa.org/?p=415