“I can truly say I have never worked with a dealer that’s so committed to their customer success, from sales, service support to ownership,” says customer Jon Kaye, who nominated West Side Tractor Sales for Equipment World’s Big Iron Dealer of the Year honor.

The vice president of equipment for Miller Bros. Construction in Archbold, Ohio, continues: “They truly build relationships with their customers, focusing on how they can help grow and bring efficiency to the customer’s business.” Kaye’s experience with West Side began during his time as fleet manager at Gallagher Asphalt in Thornton, Illinois.

That’s just the impact that West Side Tractor Sales, headquartered in Lisle, Illinois, is striving for as it navigates the highly competitive world of construction equipment.

“We make it very intentional to spend an incredible amount of time out with customers and listening to their problems,” says Brian Benck, vice president of sales and a third-generation owner. “We want to serve the person that buys one tractor every 10 years as well as offer tailored solutions to those customers that buy 100 tractors a year.”

West Side’s second- and third-generation family leadership team includes (l. to r.) Steve Benck, Diane Benck, Lauren Coffaro, Jen Snow, Brian Benck and Tom Benck.Established in 1962 by Rich and Mary Benck, West Side now serves as the John Deere dealer in more than 80 counties with 11 locations in Illinois, Indiana and Michigan. Six second- and third-generation owners – all deeply ingrained in the company’s day-to-day operations – now carry on the legacy: children Steve, Diane and Tom Benck and grandchildren Brian Benck, Jen Snow and Lauren Coffaro.

“My father picked a really good partner in John Deere in the ’60s that allows us to be where we are today,” says Diane Benck, vice president of general operations and second-generation owner.

That includes a shiny new headquarters with a state-of-the-art shop. (More on that in just a bit.)

“There’s so much opportunity to have organic growth within our footprint,” Diane says. “I’m not a big believer in buying a lot of territories. I’d rather do something really well, provide bottom-line returns while giving awesome customer service. Being twice as big and making half as much doesn’t serve any purpose. I don’t always think bigger creates the best customer experience, and that’s a priority for us.”

That’s not to say that West Side hasn’t had its share of geographical growth. Rich expanded in the ’70s to four locations in the Chicago area. The second generation added a fifth Chicago-area location and in 2010 acquired five Deere dealerships from Holt Equipment, adding 68 counties in Indiana and three counties in Michigan. New facilities have also been built in Bloomington and Terre Haute, Indiana.

The changing customer

A company that’s now in its third generation has had a front-row seat to changing customer expectations.

“Customers now have an on-demand mentality,” Brian says. “Whether it’s the sourcing of equipment or parts, customers have a much better understanding of their own efficiency, and we’ve had to tailor our model to on-demand. We have to have the inventory and have it ready to go.”

“I think we’ve gotten so much savvier about how we’re engaging customers,” says Lauren Coffaro, marketing and technology manager and third-generation owner. Social media has given the dealership the ability to get quality leads with people it didn’t have a relationship with before.

What hasn’t changed, however, is that relationships still matter, Diane says. “The basic relationship that we foster with those customers is still there.”

“Dealership of the future”

“We wanted the Lisle headquarters to be the dealership of the future,” Lauren says of the facility that opened last year.

“We put a lot of thought into our employee areas,” Diane says. And with an eye toward attracting more women, it put in separate locker rooms and a lactating room.

As it developed plans, West Side scrutinized shop processes, knowing the more time a technician spends working on a machine, instead of ancillary activities like parts runs, the less time the customer has to wait to get the machine back.

By using the vending machine, technicians are kept in the shop space and the process tightens up billing and inventory management.West Side Tractor SalesTo maximize efficiency, the shop has a vending machine that uses facial recognition to dispense commonly used parts such as zip ties, brake clean, and cleaning and grinding discs. The technician takes what he or she needs, types in a work order, and the supplies are automatically allocated. “By using the vending machine, technicians are kept in the shop space,” Lauren says, and the process tightens up billing and inventory management.

Each technician has a laptop; they can order parts and stay in the bay while parts are located and delivered to a mailbox at each bay, further eliminating wasted technician time. “Those lost minutes add up, especially in a facility as large as Lisle,” Lauren says. “Our service manager is also running a live screen, tracking all the work done each day and the time it is taking to complete a project.”

“We’ve only been in Lisle a year and the service sales are up 20%,” Diane says. The new facility also allowed West Side to add a certified Deere rebuild facility, including a clean room.

The key to staying a leader

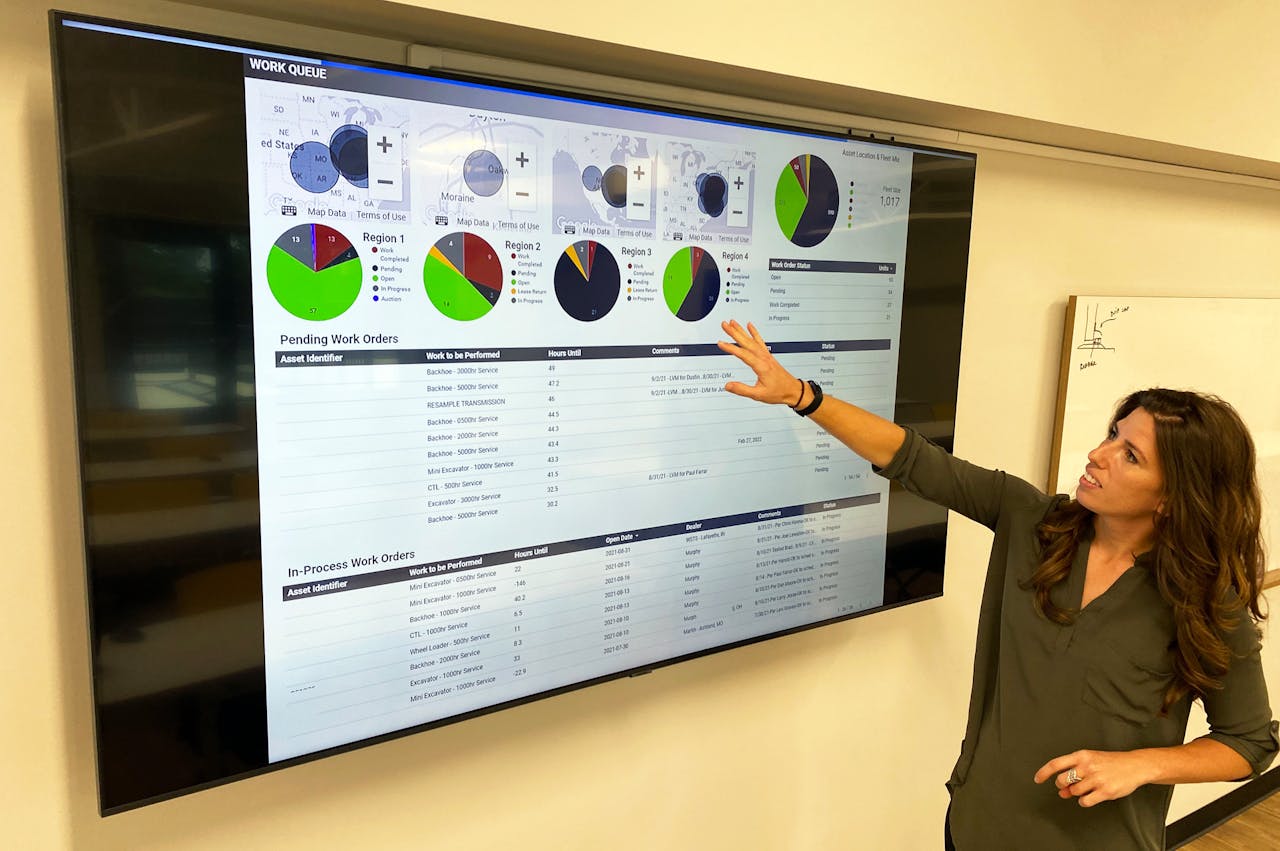

With West Side’s new fleet services initiative, West Side says it offers to “do the heavy lifting in managing our customer’s data.”West Side Tractor Sales

“We’re working really hard on our technology solutions side,” Diane says. “The use of technology is so key to staying ahead of the competition. We usually know what’s going on with their machine before they know it, and we’re calling them proactively.”

West Side established its technology division in 2015. It now offers fleet monitoring (remote support, proactive alert management and JDLink hardware sales), the positioning products (SmartGrade, grade control, off-machine instruments and drones) and its new fleet services initiative.

With fleet services, West Side offers to “do the heavy lifting in managing our customers’ data,” Lauren says. The department grew out of a customer’s request to manage their PMs in different U.S. locations. West Side now manages their equipment data and examines their lease structures. “We know we can apply what we learned in that process to other customers,” Lauren says.

One example is West Side’s new idle time reduction program. “The goal is to grow it into a portfolio of reporting products that we can sell on a subscription basis,” Lauren says.

“Sometimes it’s just listening and then making the extra effort to try to address some things that may not necessarily relate to an equipment sale that helps tie and pull that relationship closer,” Brian adds. “This is an effort to really understand what projects we can work on for customers to help them improve their operations. I see that as a total game changer that most dealers aren’t doing today.”

Noting that it was getting regular requests for basic training on its positioning equipment, West Side also started putting QR codes on this equipment this year, allowing operators to link directly into the dealer’s website and grab a quick tutorial video.

It used to be that the customer relationship was wrapped up in the dealer rep. “We have found that the most successful customer relationships are not about that one person but about creating a team that can jump in to support the customer in many different ways,” Lauren says. “We have true experts, whether in service, technology or production-class machines, that can create that world-class customer experience.”

Overcoming supply-chain shortages

Today’s global supply chain issues are ever-present in frontline operations such as West Side.

“We’ve always been a dealer that stocked more on the heavy side, so going into this we were perhaps in a better position than maybe a lot of dealers,” Brian says. “We kept our inventory levels up and continued to order.”

Used equipment pricing has gone sky high as inventory levels have dropped. “We’ve just had to get creative on how we go out and source equipment, acquiring lease returns, actively purchasing machines on the open market and using consignment programs,” Brian says.

Some pandemic-prompted changes, such as curbside parts pickup, are here to stay, says Lauren. “We had just launched our online parts portal before the pandemic, so it was easy to transition customers over to that tool.” Curbside parts pickups are now in front of all West Side branches.

The pandemic also exacerbated an already shallow talent pool, especially for ever-elusive technicians. In addition to reaching out with social media and forming relationships with tech schools, West Side is focusing on retention by using a new orientation for incoming employees. “The hardest time to keep them is when they’re new,” Diane says. “We want to make sure that they immediately feel part of the team.”

West Side’s employee culture program, Gear Up, has been in place since 2015. “We launched it with the goal of being the number one customer service provider in our industry,” Lauren says.

“We want to create ‘wow’ customer experiences throughout all of our departments. It really had us focus on our core values and creating this content that we now use for recruiting. We’re in a good place now because we have a lot of those facets that were already built out.”