Home » Construction Management (Page 5)

Category Archives: Construction Management

Secunderabad Cantonment Board recruitment for Asst. Engineer [Civil], Asst. Cantonment Planner | 06 posts | 09-10-2021

Secunderabad Cantonment Board recruitment for Asst. Engineer [Civil], Asst. Cantonment Planner | 06 posts | 09-10-2021

The post Secunderabad Cantonment Board recruitment for Asst. Engineer [Civil], Asst. Cantonment Planner | 06 posts | 09-10-2021 appeared first on ConstructionPlacements.

Did you miss our previous article…

https://constructionosa.org/?p=323

Plagued with Low Battery Life? These Chargers Will Keep Your Devices Ready to Go

Time for a battery check. You rely on your devices especially phones to power your business. But will they last a full day which in contractor terms means way past eight hours?

The good news: There are a slew of good, reliable and affordable charging options out there. But whatever you buy, be sure to look for these basics:

Size and Capacity: A good rule of thumb for power banks says the bigger the battery, the greater its capacity and the more ports it can accommodate. It’s easy to find an inexpensive one that will fit in your pocket and, with 5,000mAh, reload your phone once or twice. It’s also not hard to find something a bit more robust.

Power In. Power Out: When shopping for a charger or power bank, be sure it’s compatible with the device(s) you’ll be using it with. Most will have a USB-A port for reloading the battery and for sending the juice to your device. More and more devices are relying on USB-C ports, as they are also compatible with most fast-charging options.

And, of course, Apple has a port all its own: Lightning. However, with the Apple iPhone 12, charging can be done with a USB-C port.

So, regardless of the charger or battery pack you buy, be sure its ports match up with your device’s cords.

Wireless Charging Is a Real Thing: Newer models of smartphones and other devices may be set up to be charged without having to be plugged in. Wireless charging relies on electromagnetic induction to reload your device. In short, wireless, or Qi, charging works by transmitting power from a coil in a charging unit to a coil in the receiving device. All you do is place your smartphone or other device on the pad of the receiver.

As we said, there are hundreds of charging devices on the market. With even modest study, you can find one at a travel center, truck stop, big-box store or online that fits your device and your budget.

Here’s a few to get you started:

Jackery Explorer

To the untrained or unfamiliar, putting using this portable power station in your pickup might seem like going rabbit hunting with a Howitzer. But it never hurts to be over-prepared.

Weighing in at just a shade less than 4 pounds, the Explorer packs a big charging wallop and also provides the convenience of not having to reload it too often.

It has a 100-watt AC outlet, a USB-C and two USB-A outlets, and a 12-volt car outlet as well.

And at its heart, the Explorer has rechargeable lithium-ion batteries that provide 167 watt-hours of energy storage. That means it’ll recharge the thirstiest of smartphones 16 times.

You can refill those batteries by plugging into a wall socket (about five hours) or your truck’s 12-volt system as you drive, or hook it to an optional solar panel.

The Explorer 160 sells for about $106 on Jackery’s website.

PowerDrive’s Cup Holder Power Inverter

This device not only charges your devices, it also provides AC and 12-volt outlets so you can use your truck’s battery to power other appliances.

Fitting nicely into your truck’s cup holder, it has both USB 2.4 amp and USB-C 3 amp ports, in addition to the AC outlet, making it able to accommodate most of your charging requirements.

It has a 2-foot-long cable to plug into your truck’s 12-volt port.

PowerDrive is a member of the RoadPro Family of Brands, and the cup holder inverter is available at most travel centers and truck stops and sells for $32 online.

Nekteck PD 45W Type-C Car Charger

Don’t be thrown by the name. This’ll work in your truck and delivers plenty of power for a reasonable price – about $20 online.

This device fast-charges phones, tablets and laptops on its USB-C port and, at the same time, can charge a second phone on its USB-A port. It conforms to USB-C fast-charging standards and includes a good quality cable.

This Nekteck’s 45-watt output and its USB-C–to–C cable support the maximum charge rate on Android phones, the 2018 and 2020 iPad Pros, and some laptops. In addition, you can use the 12-watt USB-A port at the same time to charge a second phone or other device with any USB cable you already have.

MobileSpec Charging Bundles

Let’s face it; your fancy smartphone is useless if not charged. And even the best, most powerful charger is of no value if you can’t get the juice to that same smartphone. The important link is the cable (yes, yes, we know, Qi allows wireless charging, but not every person has a compatible device), and MobileSpec delivers not just a good, solid charging cable but some much-appreciated accessories in its bundles.

Each bundle has a 6-foot-long Lightning to USB or USB-C to USB braided cable that has strain relief built-in, but other goodies as well. All three bundles include five cable organizers. Then you can get a bundle with a:

● Multi-tool that has a pen, knife, bottle opener and flashlight

● Phone cardholder for up to three cards

● Three-in-one phone mount (finger, stand or dashboard venter)

MobileSpec is a member of the RoadPro Family of Brands, and its bundles and other charging devices can be found at most truck stops and travel centers. Available online for under $13.

WeeGo Jump Starting Power Pack

Don’t let the name fool you. This powerful battery can:

1. Jump-start your pickup or ATV

2. Recharge your smartphone or other device

3. Fit in the palm of your hand

That makes it ideal to keep in your truck’s cab. It literally packs a lot of power and takes up little valuable space.

WeeGo makes several power packs (including the Crankenstein, which is suitable for jump-starting duties at jobsites and repair shops), and includes the 44.1.

WeeGo’s new 44.1 weighs just a pound and a half, but its lithium-ion battery delivers 440 cranking amps, so you can jump-start most vehicles. The $129 unit also has a 12-volt port, a fast-charge USB port, and doubles as a flashlight with 500 lumens of illumination.

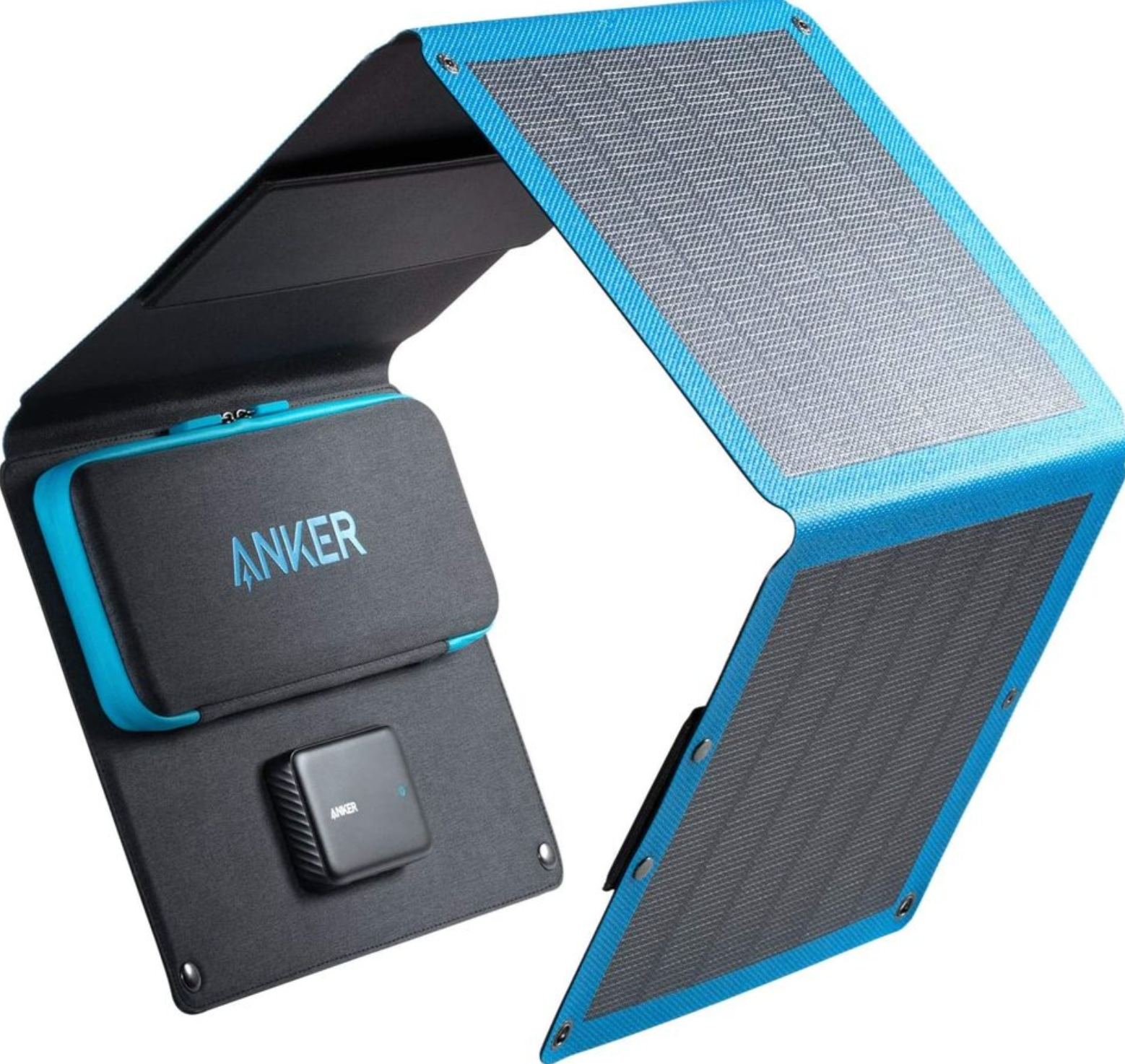

nker 24W Three-Port USB Portable Solar Charger

Anker is well known for producing reliable, affordable chargers and other digital devices. Among them is a solar charger; the Anker 24W 3-Port USB portable solar charger includes a foldable CIGS (thin-film) solar panel.

It’s suitable for iPhone 12/SE/11/XS Max/XR/X/8, iPad, Samsung Galaxy S20/S10/S9/S8. The solar panel’s three USB ports share a total 21W output, allowing you to simultaneously charge up to three devices. When you’re not charging, the PowerSolar folds away for easy storage. The built-in storage compartment can hold cables or small mobile devices. It comes with an 18-month warranty.

Available online for $79.99.

myCharge HubMax 10050 Portable Charger

The myCharge HubMax 10050mAh portable charger has an integrated Apple Lightning cable, an integrated USB-C cable and a USB port. It also has self-contained wall prongs so you can plug it into a wall socket or an inverter.

With a 10050mAh internal battery, the HubMax 10050 delivers up to 54 hours of charging power. It’s available online for $89.99.

Belkin Boost Charge Wireless Charging Stand

Belkin Boost WirelessThis wireless charging stand can reload a typical smartphone from empty to 50% in about an hour. It comes with a cable and wall plug and delivers a 7.5 W charging speed for iPhones and 10 W for Android smartphones.

The Belkin Boost is compatible with Qi-enabled devices including iPhones, Samsung Galaxy and Google Pixel. You can charge your phone in portrait or landscape modes.

Available online for $32.99.

Did you miss our previous article…

https://constructionosa.org/?p=314

Old Outer Banks bridge girders could hold key to future bridge designs

The girders of an old bridge traveled for more than 50 years by visitors to and from the Outer Banks of North Carolina could help improve future bridge construction.

The Herbert C. Bonner Bridge was dismantled beginning in 2019 after a 2.8-mile replacement bridge was constructed. The bridge withstood decades of punishment in a harsh windy, salty environment, including numerous tropical storms and hurricanes, giving researchers a unique look at how the girders held up and how much more they could take.

The N.C. Department of Transportation, through a partnership with N.C. State University, salvaged the old bridge’s concrete girders and had them transported to NCSU’s Constructed Facilities Lab in Raleigh for stress testing.

The tests determine where weaknesses develop in the girder under constant regular use. The girders are also put under extreme pressure until they break.

“What we’re trying to really investigate is the amount of prestressing in this structure,” says Dr. Giorgio T. Proestos, NCSU assistant professor, on a recent NCDOT video (watch at the end of this story).

“Is it enough or should there be less? And how does that prestressing change throughout those 60 years?”

Researchers at N.C. State University conduct stress tests of a girder from the former Bonner Bridge to the Outer Banks.NCDOTAccording to the NCDOT, it took 20,000 pounds of pressure to break one of the bridge’s girders. Sensors with cameras show how the girder reacts under pressure.

“Based on the results of the experiment, there might be changes in the way things are done moving forward,” Proestos says.

The Bonner Bridge was built in 1963 over the Oregon Inlet between the mainland and the Outer Banks. Demolition and dismantlement of the bridge began in 2019 after the Marc Basnight Bridge opened.

“This is a very unique opportunity,” says Neil Mastin, who manages NCDOT’s Research and Development unit. “It’s not often you get a bridge in that extreme environment for nearly 60 years that was intact enough that we can actually use it for testing.”

Mastin says NCDOT will publish the test results, which could have a national impact on bridge design and construction.

Check out NCDOT’s video below of the girders undergoing stress testing:

CMSBrowserComponents.load({ el: ‘#vue-1631901973011-267’, name: ‘OEmbed’, props: {“mountPoint”:”/__oembed”,”url”:”https://youtu.be/qJBMWCjzLPU”,”attrs”:{“type”:”oembed”,”id”:”https://youtu.be/qJBMWCjzLPU”,”element”:”aside”}}, hydrate: false });

Did you miss our previous article…

https://constructionosa.org/?p=294

IREL Recruitment for Graduate/Diploma Trainee and Others | 54 Posts | 05-10-2021

IREL Recruitment for Graduate/Diploma Trainee and Others with 54 Posts vacancies, last date to apply is 05-10-2021

The post IREL Recruitment for Graduate/Diploma Trainee and Others | 54 Posts | 05-10-2021 appeared first on ConstructionPlacements.

Did you miss our previous article…

https://constructionosa.org/?p=291

Lift Equipment Roundup: JLG Telehandler Places Loads Up to Eight Stories High

The new JLG 1075 telehandler is a 10,000-pound class telehandler designed to increase productivity with its 75-foot lift height that reduces the need for more costly cranes on the job site. Capable of taking loads up to eight stories, the JLG 1075 also features 60-feet of forward reach and 30-feet of up-and-over reach for more precise load placement.

Frame leveling up to eight degrees aids setup on uneven ground. Lift capacity at full height is 6,000 pounds and max reach at 2,100 pounds. A 160 horsepower Cummins engine powers the unit and provides 22,500 pounds of drawbar pull. A right-side electronic mirror with dual cameras enhances safety by allowing operators to see more.

Komatsu forklift hydrostatic drive lowers maintenance costs

The Komatsu FH100-160-1 is designed for heavy loads and long-term durability.KomatsuKomatsu’s new FH100-160-1 series of forklifts borrow technology from the company’s loaders, dozers and excavators including a hydrostatic drive that eliminates wear on drive and brake components. According to the company, the power and design of the FH100-160-1 forklifts make them good choices for industries where heavy loads are common, including freight and logistics, shipping and ports, manufacturing, construction, metal industries, oil and gas, and recycling and waste.

Compared to traditional torque converter systems, the hydrostatics on the FH100-160-1 reduce maintenance costs, fuel consumption and downtime. Sealed wet multiple-disc brakes provide protection from dust, dirt and debris, durability, fade and water resistance, and prompt, reliable braking in high-cycle operations.

New Tadano crawler crane fills gap in market

The flexible track position system on the Tadano GTC-1600 offers multiple different track width setups.TadanoThe Tadano Group has launched an all-new 160-ton tele-boom crawler crane: the Tadano GTC-1600. Designed to fill a gap in the telescopic boom crawler market, the Tadano GTC-1600 has more than 200 feet of main boom length and the ability to work on out-of-level slopes up to four degrees.

The six-section boom extends from 42.8 feet to up to 200.1 feet. The boom uses a single cylinder telescoping and pinning system to extend and retract all the sections automatically and can be locked in selected working positions.

Complimenting the boom is a 33.8-foot by 59.1-foot bi-fold jib with offsets up to 40 degrees. A jib length of up to 105 feet is possible with two 23-foot optional lattice inserts, for a maximum tip height of 305 feet. An optional 11.8-foot heavy-lift jib with 20-degree and 40-degree offsets is also available for tilt-up work in tight spaces.

Tadano’s Opti-Width flexible track position system gives you a numerous symmetrical and asymmetrical track-width setups without requiring you to pin the track frames in fixed positions. The GTC-1600’s hydraulic system makes for smooth and seamless multi-function operation, allowing travel, hoisting, and boom telescoping all at the same time.

Grove updates TMS9000-2 truck crane for more power and faster setup

Grove’s refreshed TMS9000-2 truck crane lost 1,000 pounds and gained 25 horsepower.Manitowoc

With the addition of the new Cummins X12 Tier 4 Final engine, Grove’s TMS9000-2 truck crane gains an extra 25 horsepower and now puts out 475 horsepower. In addition, changes to the outrigger design and placement enhance setup procedure, while a new rear-access ladder option adds practicality for day-to-day use.

The rear outrigger box has been raised by just under five inches to improve the departure angle to 18-degrees, while the front outrigger jacks have been raised 3.5 inches to improve ground clearance. This also makes sliding outrigger mats underneath the pads even easier. Additionally, there is now an extra three inches of outrigger stroke, while the outrigger pad size has been increased from 20 to 24 inches.

According to Manitowoc, the Grove TMS9000-2 has the lowest GVW in the 115-ton class, and the latest model has slimmed down by 1,000 pounds to a svelte 80,311 pounds for the basic configuration. The truck crane’s load charts remain unaffected, courtesy of the 36 x 169 foot six-section Megaform boom and its single telescopic cylinder with fully hydraulic twin-lock pinning system. Manitowoc’s automated laser-welding process leaves just one weld seam on the boom, rather than the previous three, to produce a higher-quality, stronger and lighter design.

Did you miss our previous article…

https://constructionosa.org/?p=271

Contractor Faces $1.35M in Fines After 2 Die in Dump Truck Incident

A Boston area contractor faces $1.35 million in penalties following the death of two workers who were hit by a dump truck and then fell into a 9-foot-deep excavation, according to the U.S. Occupational Safety and Health Administration.

The trenching, excavation and underground construction contractor was cited with 28 violations. OSHA also used its “egregious citation policy” to propose additional penalties due to the company’s history of infractions and the severity of the incident, the agency said. The policy enables OSHA to issue a separate financial penalty for each of the 28 violations.

OSHA said the contractor had been fined for 14 previous violations for a total of $81,242. However, $73,542 of those fines were unpaid and referred to debt collection. OSHA is also investigating another incident involving alleged excavation violations on August 13 on a utilities project in East Boston.

Atlantic Coast Utilities/Advanced Utilities of Wayland, Massachusetts, was the contractor on a sewer repair project in downtown Boston on February 24 when Jordy Alexander Castaneda Romero, 27, and Juan Carlos Figueroa Gutierrez, 33, died. OSHA says the penalties also affect predecessor company Shannon Construction Corporation, owner Laurence Moloney and successor company Sterling Excavation. Sterling was also the contractor on the August 13 project being investigated.

“While two families still mourn the loss of their loved ones, this employer has ignored safety violations, failed to pay fines and shown a total disregard for the safety of its employees,” said Acting Assistant Secretary of Labor for Occupational Safety and Health James Frederick. “OSHA will use every enforcement and legal tool available to hold scofflaw companies such as this and their owners accountable.”

OSHA issues citations

On February 24, Romero and Gutierrez were working on an emergency sewer repair project when an Atlantic Coast Utilities dump truck struck them while backing up and caused them to fall into the excavation.

Emergency responders found them in the hole, and they were pronounced dead on the scene.

The Suffolk County District Attorney’s Office is also investigating the incident.

The bulk of the proposed financial penalties, which total $1,350,884, were related to failing to train workers on excavation and road work hazards.

“When you fail to train your employees properly, you deny them the most valuable tool they can have, knowledge. Knowledge to do their work correctly and safely, knowledge to understand the hazards that accompany their job and knowledge of how to identify and eliminate those hazards before they injure, sicken or kill workers,” said OSHA Acting Regional Administrator Jeffrey Erskine in Boston.

OSHA also issued the following safety and health violations for the incident:

Inadequate cave-in protection. Failing to protect workers from potentially hazardous gases in the excavation. Repeat violation for workers in a trench where the pavement has been undermined.Ladder did not extend at least 3 feet above street level.No inspections program for worksites.Traffic control measures did not meet standards.Defects had not been corrected on dump truck before incident.Workers were not wearing high-visibility vests.Failure to properly document and report the two deaths to OSHA.

Cat 777G Water Solutions Truck Varies Water Output to Meet Site Conditions

As we enter the driest part of the year for many regions of the country, Caterpillar has come to the rescue of dusty worksites with a its new 777G Water Solutions truck platform.

The redesigned Cat 777G doesn’t just throw water out haphazardly, it uses a Water Delivery System (WDS) combined with Cat MineStar Edge connectivity to vary the water flow by truck speed. This conserves water and prevents overwatering and all the problems that result from turning a dusty site into a muddy one including traction and visibility issues. It also conserves water, which reduces the number of fill-ups and helps in drought prone areas.

A variable displacement pump automatically starts and stops when the truck slows or comes to a halt. Soft start-ups also eliminate excess watering, and the pump turns off automatically when the tank is empty, preventing damage to the system from the pump running dry.

The WDS components include a water cannon, oil cooler, variable displacement pump, hydraulic oil tank, electronic control boxes and a hydraulic motor and water pump. In the adaptive economy mode, the truck’s engine uses up to 13 percent less fuel than full power mode. And the water cannon operates at engine idle speed, further reducing fuel consumption by up to 50%.

Standard equipment on the new Cat 777G Water Solutions truck includes an integrated 20,000-gallon Cat-branded water tank, complete with spray system, splash guards, fill chute and rock ejectors. Remote tank fill control, complete with auto shut-off to prevent overfilling, enables the operator to remain inside the cab during refilling to reduce potential operator slips and falls. Retrofit kits are available for existing Cat 777G truck platforms in the field.

Did you miss our previous article…

https://constructionosa.org/?p=207

Toyota to Produce Class 8 Fuel Cells in Kentucky Plant

After thousands of miles of real-world testing in commercial trucking, Toyota announced today that it’s preparing to take its hydrogen-powered fuel cell electric technology from prototypes to production in its efforts toward carbon neutrality.

Starting in 2023, a dedicated line at Toyota Motor Manufacturing Kentucky (TMMK) will begin assembling integrated dual fuel cell modules destined for use in hydrogen-powered, heavy-duty commercial trucks. Fuel cell modules bring Toyota’s electrification strategy further into focus as it will allow truck manufacturers to incorporate emissions-free fuel cell electric technology into existing platforms with the technical support of Toyota under the hood.

“We’re bringing our proven electric technology to a whole new class of production vehicles,” said Tetsuo Ogawa, president and chief executive officer, Toyota Motor North America. “Heavy-duty truck manufacturers will be able to buy a fully integrated and validated fuel cell electric drive system, allowing them to offer their customers an emissions-free option in the Class 8 heavy-duty segment.”

The dual fuel cell modules, which are a key component of an overall fuel cell kit, weigh approximately 1,400 pounds and can deliver up to 160kW of continuous power. The fuel cell kit also includes a high voltage battery, electric motors, transmission and hydrogen storage assembly from top-tier suppliers. Toyota will also offer its powertrain integration knowledge to help truck manufacturers adapt these emissions-free drivetrain systems to a wide variety of heavy-duty truck applications.

“This second-generation fuel cell system is necessary for a carbon neutral future,” says David Rosier, Toyota Kentucky powertrain head. “It delivers over 300 miles of range at a full load weight of 80,000 pounds, all while demonstrating exceptional drivability, quiet operation and zero harmful emissions.”

Toyota displayed this technology at the 2021 Advanced Clean Transportation (ACT) Expo in Long Beach, California held last week.. A prototype truck powered by Toyota’s fuel cell kit was also on display.

Did you miss our previous article…

https://constructionosa.org/?p=206

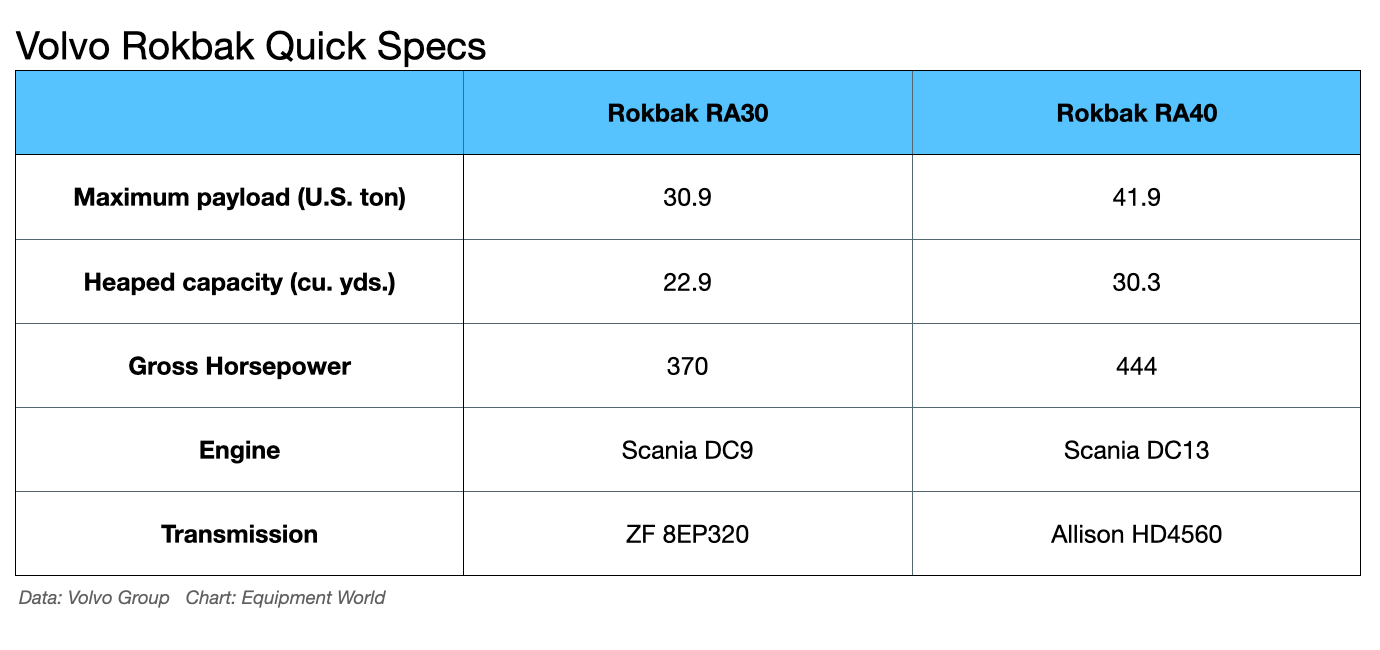

Terex Trucks Changes Name to “Rokbak” in Volvo Brand Transition

Terex Trucks is now Rokbak, in a move that removes the Terex name from the articulated truck line Volvo Group purchased in 2014.

“Now is the right time for us to carve a brand new name for our business,” says Paul Douglas, Rokbak managing director.

Under the Rokbak brand, Volvo Group subsidiary Volvo Construction Equipment is offering two models, the 30.9-ton RA30 and the 41.9-ton RA40. Coming in new colors and livery, Volvo says, the two units offer better fuel economy, lower emissions, improved safety and greater durability than the previous Terex Truck models, TA300 and TA400.

Improvements include Tier 4 engines, a new transmission on the RA30, the introduction of Haul Track telematics and an emphasis on operator comfort and safety. The RA30’s ZF transmission has a 4,000-hour oil change, and the RA40’s Allison transmission comes with a 6,000-hour oil change. In addition, the RA40’s transmission has adaptive shifting and drop-box two-speed ratios, helping the truck maintain optimum momentum, Volvo says.

The Haul Track telematics offers information such as machine location, hours, engine speed and idle time, machine operating parameters, fuel consumption and system fault code alerts.

Wide pivoting steps and service platforms provide safe and easy access to the cab.

“We already have a very healthy order book for the new brand, and we want to further expand our reputation, dealer network and market share,” Douglas says. “We’re still the same skilled, experienced, and passionate team, committed to making rock-solid haulers every day. But we also have a clear vision for where we want to go and who we want to be.”

Volvo traces the Rokbak lineage back to 1934 when Euclid Road Machinery built what Volvo calls the world’s first off-road truck, the Model 1Z. The trucks have been made in Motherwell, Scotland since 1950.VolvoRokbak has quite a legacy. Volvo traces the machine’s lineage back to 1934 when Euclid Road Machinery built what Volvo calls the world’s first off-road truck, the Model 1Z. The trucks have been made in Motherwell, Scotland since 1950. General Motors bought Euclid in 1953 and renamed its earthmoving division “Terex,” from the Latin “terra” (earth) and “rex” (king). Terex became independent of General Motors in 1987, was bought by North West Engineering in 1992, forming Terex Corporation. Volvo Group bought the off-road truck line from Terex in 2014 and marketed it until now as Terex Trucks.

“It’s important for us to preserve the heritage, expertise and relationships that have been built up over the years,” says Melker Jernberg, president, Volvo CE and executive vice president, Volvo Group. “We didn’t want to start changing everything about what made Terex Trucks so successful in the first place. It was crucial to allow the company to run with the same autonomy that it always has. As Terex Trucks rebrands to Rokbak, we see continuation of the company’s strong tradition, shaking up the industry and doing things in their own way.”

Did you miss our previous article…

https://constructionosa.org/?p=178

Drone, Software Firm Alliance Takes on Large Construction Jobs

A Doosan Group division has joined with automated analytics provider AI Clearing to provide detailed jobsite data for large-scale construction projects.

The partnership takes advantage of Doosan Mobility Innovation’s hydrogen-powered drones, reportedly the first-of-its-kind. Capable of staying airborne for more than 2 hours, the drones alleviate the need for multiple batteries and launch points required by lithium-ion polymer drones and stay airborne four times longer, says AI Clearing. And when power does get low, the hydrogen tanks can be quickly replaced, allowing the drones to be running again in three minutes.

Not only are the DMI drones capable of being in the air longer, they can also carry more payload, says Taco Engelaar, chief commercial officer, AI Clearing. “There’s a huge synergy with their drone hardware and our software,” he says.

For its part, AI Clearing says its artificial intelligence-powered system leverages automation in comparing drone images with schedules and designs, providing teams with full visibility into the work that’s been completed and spot any discrepancies to design.

While drones are commonplace on jobsites, contractors are not getting much value from the data obtained by them, Engelaar says. “The digital surface models don’t really mean much,” he says. AI Clearing’s software uses what he calls a fully automated progress tracking solution that analyzes the drone data along with project design data.

The partnership is targeting large construction projects with this joint effort, including roads, bridges, high-speed rail, solar farm and port construction.

Companies are “increasingly demanding longer flight time,” says Doo Soon Lee, CEO, Doosan Mobility Innovation. “This is the case for sites difficult to access in one flight, sites where efficiency is significantly reduced with battery drones due to large scale, or when you want to perform multiple missions using long flight time.”

Joint AI Clearing/DMI future projects could involve near real-time reporting as the drone flies over a site, something that now takes about a day because of the data processing and analytics involved. “We’re looking at ways to actually install our solution directly onto the drone and then directly transmit our progress analytics in real time,” Engelaar says, taking advantage of the drone’s heavier payload capabilities.

The joint effort will also focus on R&D with an aim to enable edge computing for construction progress that was previously impossible due to limitations in computing power and the distance capabilities of most drones, AI Clearing says.

Did you miss our previous article…

https://constructionosa.org/?p=166