Home » 2021 (Page 10)

Yearly Archives: 2021

Stellar’s New Lightweight Service Body Handles 4,000-Pound Crane

Stellar has rolled out a new lightweight, corrosion-resistant truck service body that can handle up to a 4,000-pound crane.

Designed as a mechanic’s field truck for utility and construction contractors, the new TMAX 16K aluminum service body can be equipped with Stellar’s EC3200 Aluminum Telescopic Crane, which weighs 500 pounds, 230 pounds less than its steel counterpart. The compact aluminum telescopic crane delivers 3,200 pounds of lift capacity and 15 feet of horizontal reach.

The lighter weight of the crane and service body allow for increased truck payload, the company says.

“We’re all about trying to get more payload options for people,” said Adam Opperman, Stellar product manager, at the Utility Expo in September. “So that’s why we do aluminum; it’s lighter than steel, and it’s also more corrosion resistant than steel.”

Stellar’s Light-Duty Mechanic Cranes are powered, controlled and monitored by the hand-held, remote-control Stellar Crane Dynamics Technology.

Stellar’s EC3200 aluminum crane can lift 3,200 pounds.StellarThe TMAX series includes an aluminum extrusion compartment top that has two built-in accessory mounting rails, so you don’t have to drill holes to mount equipment. The rails make removing and attaching accessories easy and reduce water intrusion into the compartments, according to Stellar.

The extruded compartment top also has wire harness channels inside the compartments for storing wires out of the way. Other features include stainless-steel billet style hinges, three-point stainless-steel compression latches, double spring over center door closures and undercoating for corrosion resistance. The body is painted with a two-part polyurethane enamel paint for added protection and visual appeal, according to Stellar.

Contractors who need a welder body might also want to check out Stellar’s TMAC 1-11, which features a 30-inch workbench bumper with slide-out tray to serve as a workstation for torch cutting and welding.

“The trays’ removable support slates allow for blow-through to the ground, keeping your workspace clean, and the 2-inch V channel that run the length of bumper make for easy clamping,” the company says.

The welder body is equipped for Stellar’s TC Series Cranes, which also use hand-held remote control.

Stellar TMAX 1-11 Welder BodyStellar

Did you miss our previous article…

https://constructionosa.org/?p=818

Hitachi Rolls Out ZW100-6 Wheel Loader for Lighter Jobs

Hitachi’s new ZW100-6 is a small, yet powerful wheel loader well-suited for lighter applications, including landscaping, excavation, earthmoving and utility work.

With an operating weight of 17,042 pounds, the compact model is powered by a Deutz engine providing 101 horsepower and 9,680 pounds of breakout force. The engine meets Tier 4 Final emissions requirements through a selective catalytic reduction system that injects urea into exhaust gas to reduce nitrous-oxide from emissions and eliminates the need for a diesel particulate filter. Hitachi says the engine also features a quick power switch that increases engine output when required or when driving uphill.

Bucket capacity on the ZW100-6 is 1.4 cubic yards, and the machine has a maximum hinge pin height of 11 feet 6 inches.

A hydrostatic transmission control system makes the machine easier to maneuver. Operators can choose between two work modes based on the task and terrain. The oscillating rear axle provides more stability and traction than loaders with a fixed axle, the company says. When working in wet or slippery conditions, torque proportioning differentials help avoid tire slippage, preventing wear and fuel waste. The ride-control feature minimizes machine pitching for a smoother ride and to reduce bucket material spillage.

Compared to previous models, the ZW100-6 uses 6% less fuel during V-shape loading and 19% less fuel during traveling operations. Fuel waste is further reduced through the standard auto idle shutdown.

The ZW100-6 offers a clear view of the jobsite with 360-degree visibility from the cab. The repositioned muffler and air intake improves visibility out the back window. The curved engine hood further enhances visibility and safety. Improved insulation in the cab reduces noise levels, making for a quieter work environment.

An easy-to-open wide engine cover allows for easy access for ground-level maintenance. The engine air filter has been relocated to the rear of the engine compartment. The reinforced front frame features heavy-duty axles, designed in-house for increased durability. An optional belly guard can be added to protect the powertrain and driveshaft.

The ZW100-6 is also equipped with Hitachi’s Global e-Service for 24/7 remote monitoring of machine performance. The company’s ConSite program sends automated monthly service reports on daily working hours and fuel consumption data; statistics on the operating mode ratio, plus a comparison for fuel consumption/efficiency, and emissions.

After adding the new ZW100-6, the Hitachi ZW-6 wheel loader lineup now includes 15 models.

Did you miss our previous article…

https://constructionosa.org/?p=815

Fixing “Malfunction Junction”: Work to Begin on SC’s Biggest Infrastructure Project

South Carolina’s “Malfunction Junction” will eventually earn the name of “Carolina Crossroads” as work is scheduled to begin this month on untangling the congested, dangerous interchange at I-20, I-26 and I-126 in Columbia.

The reconstruction – South Carolina’s largest infrastructure project in its history – is estimated to cost $1.7 billion and take eight years to complete. Gov. Henry McMaster and other dignitaries attended a groundbreaking Monday, and the SCDOT says work will begin in two weeks.

The work involves widening 14 miles of interstate highway in five phases. A joint venture of Archer Western and United Infrastructure won the $210 million contract for the first phase. It will include reconfiguring the Colonial Life Boulevard interchange on I-126, as well as improvements on I-26 toward U.S. 378.

Archer-United also won the $127 million contract for the second phase, which will update the Broad River Road interchange at I-20 and lengthen the I-20 westbound access to I-26 West. Both phases are expected to be completed by the end of 2024. The remaining three phases have not yet been awarded.

The rebirth of “Malfunction Junction” into Carolina Crossroads will occur in five phases.SCDOTAlong with widening 14 miles of interstate, the entire project involves building 43 new bridges and 132 new lane miles; reconstructing seven interchanges, including replacing outdated cloverleaf loops with modern ramps; and creating safer interchange exits that are farther apart and separated from other interstate traffic, according to SCDOT. The project is funded 90% federal and 10% state.

The three-interstate interchange is traveled by more than 134,000 vehicles each day, SCDOT says, causing more than 112 hours of traffic delays each year due to congestion.

The roadways are outdated, built in the 1950s and 1960s with the last updates in the 1970s and 1980s, according to SCDOT. The region is also expected to see a 70% population increase by 2024, causing even more traffic congestion. The agency says the interchange sees a higher crash rate than other freeway-to-freeway systems in the state.

Did you miss our previous article…

https://constructionosa.org/?p=812

Ditch the Shovels with the Mud Dog 700 Vacuum Excavator

For contractors who want to prevent underground utility strikes but don’t need big equipment, Super Products is rolling out its new Mud Dog 700 vacuum excavator.

The company equipped the Mud Dog 700 for working in tight, small spaces without sacrificing payload, with its 7-cubic-yard debris body and a 600-gallon water tank. It’s also much safer and faster than using shovels, the company says.

The vacuum excavator can dump at up to a 50-degree angle and into a 48-inch container. It has a low overhead height and center of gravity. The dump body also has an electric vibrator to shake material out of the bed and an auto-deploying tailgate.

The Mud Dog 700 vacuum excavator features a 7-cubic-yard debris body and a 600-gallon water tank.Equipment WorldThe boom can extend to 18 feet and rotates 270 degrees. At 8 inches in diameter, it is mounted to the rear of the truck. It can tilt 10 degrees.

The Mud Dog 700 comes standard as a hydro excavator but can be equipped with an air excavation package. It can be operated by wireless or wired remote control.

The water system pumps up to 11 gallons per minute at 3,000 psi. The vacuum system produces 3,100 cubic feet per minute of suction. A 3,700 cfm vacuum pump is an available option.

Other options include a scale system, grounding system, a debris body level sensor, a toolbox and safety cameras that give a 360-degree view around the truck. A variety of truck chassis configurations are available in either manual or automatic transmission. The Mud Dog 700 displayed at the Utility Expo in September was mounted to a Peterbilt tandem-axle truck.

A 4,000 BTU water heater is also available with heated lines for working in freezing temperatures.

The Mud Dog 700 vacuum excavator from Super Products is designed to be compact yet powerful for smaller jobs.Equipment World

Wacker Enters Compact Utility Loader Market with SM100

Wacker Neuson has entered the compact utility loader market with the SM100, which has a 1,000-pound rated operating capacity.

“We feel this machine fits our channel well,” says Joe Miller, vice president of sales and marketing, Wacker Neuson. He also notes that this machine category has seen significant growth in the past few years.

Featuring 9-inch-wide tracks for applications requiring low ground pressure, the 35.5-inch-wide SM100 easily fits through doorways and gates. Powered by a 24.7-horsepower Yanmar diesel, the 3,000-pound-operating-weight unit has a radial lift path and a hinge pin height of 85.7 inches for dumping into high-sided trucks.

The step-up-and-go spring-loaded operator’s platform uses an operator presence system to prevent accidental movement of the lift arm and travel functions. If an operator steps off the platform, these functions are no longer operable. “Some of the early designs in the industry required an operator to hold on to operate, which is taxing to your hands,” Miller says. “Now you simply stand on the machine.”

The Wacker Neuson SM100’s controls and hand rests are designed to reduce operator fatigue.Equipment World”We spend a lot of time on the controls,” Miller says. Forward-angled joysticks position the operator’s hand in the neutral position. The left hand rest circles the left joystick, and the right hand rest provides a straight segment for grabbing, giving additional stability when going over rough terrain. “You can rest your hands on here and get full mobility with the machine,” Miller says. “Especially in rental, you’re dealing with a lot of novice operators, so you want the controls to be ergonomic and simple to use.”

A sloped hood gives visibility to attachments and the front work area. A common industry attachment interface allows the use of compatible attachments. Front-mounted coolers keep hot or dirty air off the operator’s legs. In addition, the triple-flanged rollers on the undercarriage reduce wear and de-tracking. “The raised drive motor is out of the dirt, which helps provide undercarriage reliability and long life,” Miller says.

Wacker Neuson has several entries in the compact equipment field, including skid steers, compact track loaders and compact excavators, and started looking at adding a compact utility loader four years ago, he says. (Wacker calls the machine a “utility track loader.” The exact nomenclature for these machines is still shaking out; competitive machines have also been called compact track loaders, mini skid steers, mini track loaders and stand-on skid steers.)

The SM100 is produced in the company’s Menomonee Falls, Wisconsin, plant.

Did you miss our previous article…

https://constructionosa.org/?p=805

Backhoes Adapt to Fend Off Compact Competitors

In the past, the backhoe loader’s name was a complete description of what it offered: a backhoe in the back and loader arms up front, nearly always fitted with a bucket.

But that’s been changing as compact equipment eats away at the market share of what once was a mandatory machine for any dirt-moving contractor.

“The backhoe loader, maybe more than any other ‘traditional’ piece of construction equipment, has been affected significantly by the explosion of compact equipment,” says Ed Brenton, product manager, Case Construction Equipment.

One way OEMs have kept backhoes competitive against compact equipment is by adding versatility – an important, but difficult challenge.

Although backhoe-specific quick-attach systems exist, backhoe loader arms aren’t well suited for common quick-attach hardware, such as a skid steer plate.

The 97-horsepower New Holland B95C has a 14-foot 6-inch dig depth and 11-foot 5-inch height to hinge pin. Backhoe digging force is 12,969 pounds. Loader breakout force is 14,712 pounds and lift capacity is 11,118 pounds. (All figures are maximums and vary with configuration.) The B95C LR Long Reach model provides greater dig depth and a 22-foot 4-inch reach. The B95C TC Tool Carrier model features mechanical self-leveling of the loader both up and down.New HollandRyan Anderson, product marketing manager, New Holland Construction, says there are no backhoe-specific attachments such as a cold planer made for use with a compact track loader. Despite this, customers are ordering attachments, he says.

Brooms and forks are popular. Machines that retain a bucket on the front are often fitted with a 4-in-1 bucket for versatility. On the dipper, hydraulic hammer/breakers and compaction tools are the most common options, and a thumb is a staple component.

The intrusion of compact equipment into backhoe market share varies somewhat depending on the part of the backhoe catalog being considered.

“The bigger backhoe loaders, those of 90 or more horsepower, still do what they’ve always done,” says Anderson. This includes road, water and drainage tasks. “Smaller jobs often go to compact track loaders and compact excavators.”

Economics weighs into a customer’s choice of equipment. “A backhoe may be $100,000 and a compact track loader and compact excavator together may be $110,000,” Anderson says. “So for not much more money, you’re getting two very versatile pieces of equipment.”

The 420 XE is one of five new models from Cat in the 14- and 15-foot size classes. Common to all five models is the use of a Cat C3.6 engine, adjustable auxiliary flow to the backhoe and a redesigned operator display featuring soft-key controls for simpler navigation. The 420 XE also has seat-mounted controls that swivel with the operator, electronic loader controls that enable selectable parallel lift and programmable loader kick-out and return-to-dig functions.CaterpillarBrenton says there are markets and applications where backhoes retain good market share: municipalities, utilities, large site construction and development and road construction.

What traits make backhoe loaders well suited for these jobs?

“The roading speeds. The ability to work as a loader, trencher, excavator and material handler,” says Brenton. “It’s a versatile piece of equipment that you can drive from site to site.”

He uses the example of a broken water main at 2 a.m. and the ability of a worker to drive the backhoe to the site and start digging before a compact excavator could be put on a trailer.

Yet even in these traditional markets, backhoes have had to make changes to improve performance and increase productivity.

Move to electric

Another way OEMs are seeking to expand the backhoe market is the development of electric models.

The electric Deere 310 X-tier most closely aligns with the company’s 310L. The X-tier model has a 14-foot 1-inch maximum dig depth, 6,602-pound loader capacity and 22.8 mph maximum travel speed. The two backhoes vary significantly in weight, however, at 14,669 pounds for the 310L and 16,119 pounds for the X-tier. All these specs are preliminary and subject to change before the X-tier goes into production.John DeereDeere gave contractors and others a first glimpse of the 310 X-tier E-Power at The Utility Expo in September. “The 310 X-tier is geared toward customers who have stated carbon emissions-reduction goals,” says Justin Steger, Deere solutions marketing manager.

The 310 X-tier is in real-world testing with utility client National Grid. Deere consider this to be part of its early first-phase development of clean energy solutions. Phase 2 testing will begin in 2022.

Case has introduced the 580 EV electric model, which was delivered to National Grid in January. The machine is powered by a 480-volt, 90 kWh lithium-ion battery pack. A full charge is expected to be sufficient for an 8-hour workday, depending on application.

Charging can be done with any 220-volt, three-phase connection. Because the battery separately powers the drivetrain and hydraulic motors, Case says, the 580 EV has breakout force equivalent to its diesel counterpart and provides better performance than that diesel model when both the loader and drivetrain are in use.

Shift in philosophy

As backhoes’ share has dwindled in recent years under the assault of compact equipment, manufacturers have had to change not just their machines but their philosophy.

It was once assumed every contractor would have a backhoe and nearly all did. Now OEMs have to consider what segment of the overall market still uses backhoes and what features they seek.

“Electronics are coming in,” says Anderson. “The next generation of backhoe loaders will have much more technology in the controls plus advanced displays.”

He says CNH Industrial is investing heavily in electrification, and that will affect backhoe design at some point.

Brenton says that in the current climate of highly competitive bidding, backhoes can provide critical cost savings that allow contractors to remain in contention for jobs. Carrying costs and fleet management for smaller contractors and owner/operators can be challenging, and backhoe loaders allow those businesses to own and maintain a single piece of equipment that serves many functions. “That won’t work for everyone,” he says, “but it’s a model that many owner-operators have been leaning on for years.”

Cab amenities on new Case backhoe loaders include hands-free Bluetooth radio and new cushioning on their air-ride seats. A new optional air-ride, heated seat features multicolored, hand-stitched fabric. A new electronic fuel priming system, standard on all 580N and larger models, purges air from the fuel lines to simplify filter changes.Case CEBrenton lists Case features that add to the do-all capabilities of backhoe loaders. PowerBoost gives a momentary increase in hydraulic power. Direct Drive engages the engine and transmission directly for improved gradeability and faster roading speeds. A factory-installed thumb mounts independent of the bucket and so remains in place after a bucket swap. New loader control functions and backhoe control roller switches improve control at both ends of the machine. (Features vary by model.)

Key machines

The design philosophy at Kubota includes adding versatility, but it is tightly focused on providing features that make backhoes better at what they’ve always done.

The largest of Kubota’s three backhoe loaders, the M62 has a 63-horsepower Kubota engine and six-range HST Plus transmission. Four-wheel drive with differential lock on the front axle is standard. Loader lift capacity is 3,960 pounds. Hydraulic flow is 30.9 gallons per minute, and rear PTO specs are 46 horsepower and 540 rpm. Backhoe dig depth is 14 feet 1.8 inches. Operating weight with loader, backhoe and ROPS/FOPS is 8,925 pounds.KubotaThe two larger models in its three-model lineup, the L47 and M62, include a backhoe crawling mode allowing the operator to creep the machine forward or backward for repositioning while at the backhoe controls. A throttle-up switch increases the power and speed of attachments while maintaining consistent travel speed.

A hydraulic two-lever quick coupler on those two machines allows fast and easy attachment swaps on the loader arms. Popular loader-end attachments are buckets, pallet forks, grapples and brooms.

The backhoe also has a quick coupler to expedite bucket and attachment changeovers. These features are especially valuable in disaster relief and cleanup, an increasingly common task for municipalities.

Matt Walker, product manager, Kubota Tractor Corporation, points out that the B26, the company’s smallest TLB (Kubota refers to these machines as tractor loader backhoes, hence TLB) still offers plenty of performance. “The innovative B26 has an operating weight of 4,001 pounds, front loader lifting capacity of 1,102 pounds and a backhoe dig depth of 8 feet 4 inches. With its integrated front loader and quick-detach backhoe, the B26 is compact in size but capable of taking on big jobs.”

The John Deere 310SL is powered by a Deere PowerTech engine rated at 103 net horsepower. A Deere PowerShift transmission features AutoShift that automatically shifts the transmission based on engine rpm and ground speed. Mechanical front-wheel drive with limited slip is standard and can be momentarily engaged on the fly with a button on the loader control. Lift mode boosts lift capacity up to 15% by setting the engine to 1,400 rpm and maximizing hydraulic pressure for lifting.John DeereL Series models from John Deere have redesigned loader control valves to reduce hydraulic drift and improve metering and control. Maximum auxiliary hydraulic flow has been increased to 35 gallons per minute to run a wider variety of higher-flow attachments. The loader lever linkage has been redesigned to reduce resistance and improve throw and feel.

The Deere 310SL is a 14-foot dig depth model that yields up to 16% greater productivity in trenching over previous designs. An optional LED boom light kit now includes two boom-mounted work lights.

The 310SL now has pressure-compensated, load-sensing (PCLS) hydraulics for better multifunctioning, smoother machine control and up to 15% greater craning capacity in Lift Mode.

Precision mode cuts hydraulic flow by 55% for precise backhoe work without loss of overall hydraulic lift capacity. Autoshift is now standard. Optional Auto Ride Control eliminates the need to turn ride control on and off during load and carry applications.

“We also offer the 310L EP,” says Juston Steger, solutions marketing manager, Deere. “Since its introduction in 2012, the 310L EP continues to deliver exceptional value to price-conscious customers and rental companies.”

The powertrain in the current model features a synchromesh hydraulic transmission. That transmission in addition to a more basic operator station enables a lower acquisition point than the model’s previous design.

The B95C remains New Holland’s backbone backhoe and is especially popular with cemeteries and government customers. It is also available with a TC (toolcarrier) configuration, “but that’s a small percentage of total B95C sales,” says Anderson.

In its most popular configuration, the JCB 1CXT has a 49-horsepower engine that requires no aftertreatment; an enclosed cab with HVAC; ISO/SAE changeover; 8-foot extending dipper for a dig depth of 10 feet 1 inch; and skid steer quick hitch. Buckets include a 24-inch excavator bucket with teeth and a 71-inch general-purpose loader bucket with toeplate. Tracks are 12.8 inches general purpose style.JCBOf its eight backhoe models, the one JCB chose to highlight for this article was the 1CXT, which is a hybrid between a compact track loader and a backhoe loader.

“The 1CXT combines skid steer and excavating capabilities in a compact machine with a small footprint, versatility and maneuverability,” says Galvin Rodriguez, backhoe product specialist, JCB. Overall width is under 6 feet, and height is 7 feet 6 inches.

The 1CXT is JCB’s response to the encroachment of compact equipment on backhoe market sectors. It offers typical compact advantages, such as a small footprint, excellent maneuverability, great versatility, compatibility with skid steer attachments and ease of transport, while delivering backhoe operations in confined spaces.

The Power Management System (PMS) gives the operator control of speed, responsiveness, tractive effort and anti-stall. The 1CXT kingpost side-shifts the entire width of the machine. Vertical stabilizer legs allow parallel trenching along walls and fences.

An optional handheld auxiliary tool circuit converts the 1CXT into a self-contained power source for worksite tools, including disc cutters, drills, impact drills and trash pumps.

Did you miss our previous article…

https://constructionosa.org/?p=781

Reconstruction of First I-40 in N.C. Wins Top National Award

A $102 million reconstruction of the first section of Interstate 40 built in North Carolina has won a top national transportation award.

The I-40 section was built in 1958 and has been reconstructed into a 1.2-mile gateway to Winston-Salem. It was recently named the Grand Prize winner in the 2021 America’s Transportation Awards. The honor is sponsored by the American Association of State Highway and Transportation Officials, AAA and the U.S. Chamber of Commerce.

The roadway had been known as I-40 Business, but in February 2020, it opened as the new Salem Parkway – six months ahead of schedule, according to the N.C. Department of Transportation. The contractors were able to achieve the faster schedule after a decision was made to close both lanes of traffic on the highway – a first for the state.

“This has been an unprecedented feat,” said NCDOT Division 9 Engineer Pat Ivey at the time of the parkway’s opening. “Never in the history of our state has a section of freeway been closed in both directions at the same time for reconstruction.”

One of two new pedestrian bridges over the reconstructed Salem Parkway in Winston-Salem, North Carolina.NCDOTIt was estimated the project would have taken six years without the complete closure. Instead, it was completed within two years.

The contractor was a joint venture of Flatiron Constructors and Blythe Development. It hired 41 contractors and subcontractors, involving about 600 workers, according to NCDOT.

The project consisted of 10 bridge replacements, two new pedestrian bridges, a walking and biking path and extended sidewalks, as well as aesthetic improvements. Other improvements included pavement rehabilitation, safety upgrades and reconstructed shoulders and ramps.

People’s Choice Award

The Kansas Department of Transportation’s project to revamp an old Kansas City interchange that had been a dangerous eyesore won the People’s Choice Award, which is based on online voting.

The Turner Diagonal Interchange was built in the 1960s and was supposed to have toll booths, but they were never installed. That left miles of “obsolete and hazardous ramps, cutting off land prime for development,” according to AASHTO.

The $30 million KDOT project redesigned the interchange to make it safer, reduce traffic congestion and improve access to public transit. It also boosted the local economy by improving access to area businesses and created thousands of jobs, AASHTO says.

The reconstruction of the Turner Diagonal interchange in Kansas City, Kansas, won the People’s Choice Award in the America’s Transportation Awards competition.Kansas DOTThe NCDOT and KDOT each won $10,000 to be donated to a charity or transportation-related scholarship program of their choice. They were chosen among a field of 80 nominations and 25 state DOTs.

For more details about the award, click here.

Striking Deere Workers to Vote on New Deal

If UAW workers at 12 plants in Iowa, Illinois and Kansas agree to a new six-year contract with Deere & Company, the strike that had the potential to create even more supply-chain woes for construction equipment customers may be at an end.

Picketers will remain at facilities until union members give their approval to any agreement, a vote that the Waterloo Courier in Waterloo, Iowa, says will take place Tuesday.

If the new deal is ratified by the UAW membership, it would mean that the two-week strike that began on Oct. 14 would be over much quicker than the last time Deere workers walked the picket line in 1986. That strike lasted more than five months.

The Waterloo paper says the proposed contract includes a 10% increase in the first year, and 5% raises in the contract’s third and fifth years. In addition, the proposal includes 3% lump sums in years two, four and six of the contract along with cost-of-living adjustments.

UAW members would also get a ratification bonus of $8,500 and no increase in health insurance cost. New hires would receive coverage after 30 days, and members would receive two weeks of full-paid parental leave, vision and autism care coverage, says the paper, citing the UAW Local 838’s Facebook page.

The new deal means that entry-level Deere union employees would see an immediate increase in hourly wages from $20.12 to $22.13, says the Des Moines Register. Deere will reinstate quarterly cost-of-living adjustments that workers lost in their 2015 contract. Throughout the life of the six-year contract, the UAW expects workers to receive a 30% increase in wages; the contract ends in 2027.

Deere also added lump-sum payments for future retired employees, says the Des Moines paper. Employees who stay with the company for 10 to 24 years would receive $37,500; workers who stay beyond that would get $50,000. Deere would also give employees an extra $2,000 for each year worked at the company.

Did you miss our previous article…

https://constructionosa.org/?p=722

Navillus Executives Facing Up to 20 Years in Prison for Embezzlement

Three former executives at one of New York City’s largest construction firms have been found guilty of embezzlement, according to the U.S. Attorney’s Office for the Eastern District of New York.

Between 2011 and 2017, Donal O’Sullivan, Navillus Contracting’s founder, owner and former president; Padraig Naughton, former financial controller; and Helen O’Sullivan, former payroll administrator, engaged in a scheme to avoid making required contributions to union benefits funds.

The defendants violated collective bargaining agreements and skirted more than $1 million in contributions to union employees’ health, pension and vacation funds.

The trio executed the scheme by placing Navillus’ employees on the payroll of a separate consulting company. The consulting company then issued weekly paychecks to Navillus employees for work done on Navillus construction jobs. To conceal the scheme from auditors, the construction company issued fraudulent invoices.

On October 22, the defendants were convicted on all 11 counts including wire fraud, mail fraud, embezzlement from employee benefits funds, submission of false remittance reports to union benefits funds and conspiracy to commit those crimes. Each faces up to 20 years in prison.

Navillus employs more than 1,000 workers, according to its website. The company specializes in commercial concrete, masonry, tile, stone, carpentry and general contracting.

Did you miss our previous article…

https://constructionosa.org/?p=719

Sneak Peek: Kioti Lifts the Veil on Its Coming Compact Equipment Line

At the recent GIE + Expo, Kioti Tractor took the wraps off its new skid steer loader, which it expects to have in dealers’ hands by the second half of next year.

Along with a coming compact track loader that it also announced at its dealer meeting late last year, the skid steer represents Kioti’s coming foray into compact equipment. The two machines will expand its equipment offering beyond the utility tractors, UTVs and lawn mowers now on the Daedong-USA subsidiary’s product list.

Kioti also indicates that a compact excavator may be forthcoming. “We have a roadmap and mini excavators are something we’re looking at as well as other platforms that are hot right now,” says Greg Bibee, Kioti director of strategic sales and marketing, in an interview with Equipment World.

Kioti has hired Jason Boerger, formerly Bobcat’s excavator marketing manager, as its compact construction product manager.

“Having Jason on board is part of our journey into more compact construction equipment and building the team around it,” Bibee says. “This goes beyond just the equipment we are going to launch initially.”

Initial products

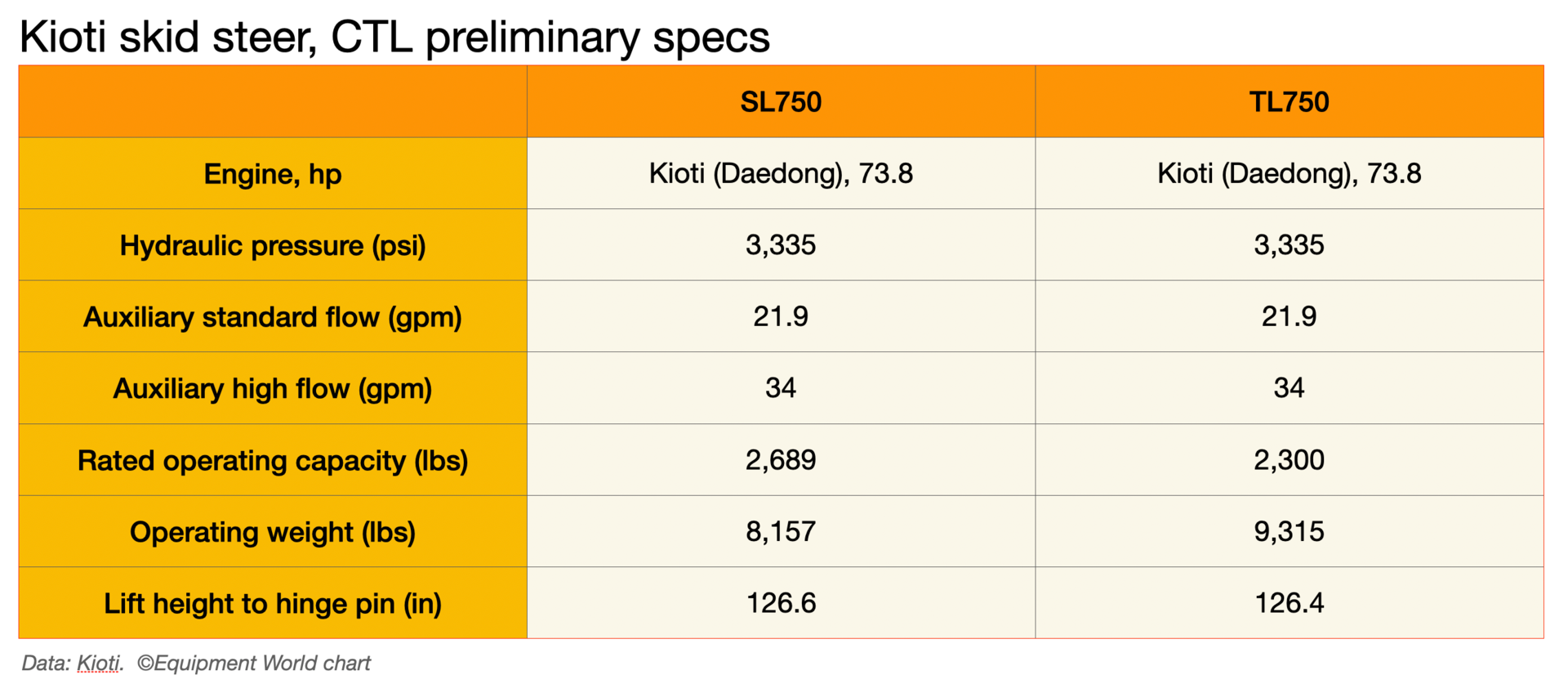

Kioti says it’s still finalizing the base and optional features of the SL750 skid steer and TL750 CTL, which will be launched in “a couple of different versions,” says Bibee.

As indicated in last year’s release, the SL750 and TL750 (both model names are still preliminary, by the way) will be powered by a 74-horsepower Kioti engine, which comes from the firm’s South Korean parent Daedong.

“It will be a similar engine to what we use in our RX Series of tractors,” Bibee says.

The initial versions will have full cabs although an ROPs option is likely. “We’re still evaluating the potential take rates of certain features and options,” says Boerger. The entry door on the vertical-lift units will slide up instead of opening to the side.

Additional recently released specs include a hydraulic pressure of 3,335 psi, auxiliary standard hydraulic flow of 21.9 gallons per minuteand high flow for both machines of 34 gpm. (Additional specs are in the chart below the article.)

Kioti cautions that the second half of 2022 timeline for these products is also dependent on global supply chains settling down to at least a somewhat normal delivery schedule. Both machines will be manufactured in South Korea.

Why enter a crowded market?

The Kioti SL750 skid steer and TL750 compact track loader.Kioti Tractor

Bibee says Kioti gets asked this question a lot. The simple answer is that it’s the logical next step in the company’s growth. The company entered the U.S. market in 1986, offering under-100-horsepower utility tractors. It added utility vehicles in 2015 and introduced a zero-turn mower line in 2019.

“We’re looking at both our dealer network and current customer base and seeing what products would bring new customers into their stores,” Bibee says. “For our current customers, it gives them more types of equipment.”

Bibee says there are similarities with the company’s recent foray into turf care and the compact equipment effort: both are aimed at professionals in addition to the DIYer or hobby farmer attracted to Kioti’s other products.

Bibee sees Kioti’s coming compact line evolving similarly to its turf care line. “We started with seated zero-turn mowers, where the bulk of the market is,” he says. The company is now offering stand-on mowers and Kawasaki engines. “We’re going to target where we best serve the market and where we feel there’s the biggest opportunity,” he says.

Boerger says he was attracted to Kioti’s strong dealer network plus the opportunity for growth within the construction, landscaping and agricultural markets. “Being able to jump in at ground zero so to speak and help bring the product to maturity is an exciting opportunity.”

“I had a chance to peek at the product early on and was very happy with what I saw, including the company’s attention to serviceability and performance,” Boerger continues. “Kioti dealer-customer relationships are also a strong differentiator.”

Kioti has more than 500 dealer locations in North America. “We’ve got a healthy pipeline right now of new dealers coming on board,” Bibee says.

Not all current Kioti dealers offer the company’s full product range, and Kioti is seeking dealers that have the right business plan, sales strategy, shop facilities and staffing to take on its new construction line.

There is a mix in Kioti’s dealer network, with some dealers tractor only, some offering tractors and turf care and still others that will take on Kioti’s eventual full line. Bibee says Kioti is also looking “at alternative dealer arrangements” where dealers choose on a more line-by-line basis what to carry. “It’s going to be highly dependent on the market and if there’s an opportunity to sell in some hot spots,” he says.

Did you miss our previous article…

https://constructionosa.org/?p=715