Home » 2021 (Page 11)

Yearly Archives: 2021

International Refreshes Medium-Duty Truck Line for First Time in 4 Years

International Truck has unveiled a newly refreshed medium-duty MV Series, for the first time in four model years.

When International debuted the MV Series in early 2018, it completed the company’s Project Horizon product refresh and brought driver comfort and fit and finish to Navistar‘s medium-duty segment. In re-tooling the MV Series, International focused on increasing maneuverability, visibility and safety with an extra splash of exterior styling – namely a restyled bumper and black molded-in-color grille with optional chrome surround.

When it first debuted, the Class 6/7 truck, which replaced the DuraStar, missed out on many of the aerodynamic refinements found on its Project Horizon-inspired siblings like the LT and RH series. This go-around, the MV Series gets an aerodynamic hood, which along with breakaway mirrors, provides improved visibility.

Debbie Shust, vice president of medium-duty truck, noted that while the MV Series was designed to look good, it was also designed to work hard and work safely, and Vice President of Marketing Diane Hames noted that the refresh after four model years was “an evolution, rather than a departure, from our existing strategy.”

Several optional collision mitigation enhancements are also available including Bendix Wingman Fusion System technology with adaptive cruise, enhanced collision mitigation, multilane vehicle braking, stationary object alert, lane departure warning, and front radar and cameras. The Bendix BlindSpotter Collision Warning System is equipped with side object detection alert.

Built for upfit

When it first debuted, the Class 6/7 MV Series, which replaced the DuraStar, missed out on many of the aerodynamic refinements found on its Project Horizon-inspired siblings like the LT and RH series.International TruckThe MV Series was also designed with upfitters in mind. A high-efficiency cooling module eliminates mega-brackets enabling integrated front frame extensions and an improved snowplow upfit offering. Smart chassis packaging changes allow for improved body integration and improved operating costs for a wide variety of applications.

The Diamond Logic electrical system comes standard, allowing for customized programming for driver and equipment protection, ease of body integration and greater uptime. Hundreds of off-the-shelf features exist today for improved safety, examples of which include: driver safety with the inclusion of pre-trip light inspection, safety on the jobsite with external regen warning, and equipment protection with hydraulic oil power take-off (PTO) shutdown and an outrigger stowed interlock.

Hood-mounted splash panels and on-engine air cleaner provide improved under-hood access while an optional under-hood work light is available for improved visibility during daily maintenance checks.

The MV Series offers two engine options – the Cummins B6.7 and L9 – with increased fuel efficiency as well as extended and aligned maintenance intervals. Corrosion protection is also improved with InterCoat ChemGuard standard on the cab floor as well as optional LINE-X offering for particularly tough environments.

The new MV Series is supported through OnCommand Connection, Navistar’s remote diagnostics system, offering the industry’s most comprehensive portfolio of connected vehicle services. Customers have the option to receive real-time information to protect their assets through GPS and geofencing capabilities as well as easy-to-understand and actionable vehicle health reports.

The new MV Series includes the option for customers to add International 360 – the service communications platform that makes it easier than ever to seamlessly communicate with the International service network and streamline the repair process.

Did you miss our previous article…

https://constructionosa.org/?p=712

Toolbx Delivers Materials, Supplies Within 2 Hours

Contractors, foremen and most construction workers know what happens when a crew comes up short of materials, tools or supplies on a jobsite. Suddenly, you have a bunch of high-skilled, high-wage people standing around with nothing to do.

That’s the problem Erik Bornstein, CEO of Toolbx, set out to solve four years ago. Bornstein spent 15 years in the construction industry building a successful company in the custom home and commercial building markets and saw the knock-on effects of supply and material interruptions first-hand. Additionally, he felt the normal process of securing supplies and materials seemed riddled with slow-downs, uncertainties and inefficiencies.

The new company he founded, Toolbx, is aimed squarely at solving these inefficiencies with an app that allows users to order almost any type of material or supplies and have them delivered, if need be, within two hours.

“I saw a huge lack of technology available specifically for procurement of construction materials,” says Bornstein. “And yet 50% of the budget for any project is for materials – whether it be a small remodel, a medium size home, or a large commercial building.”

Bornstein identified three basic problems in the construction materials acquisition process:

One: guys leaving the job site, to go pick up materials, multiple times a week.

Two: the lack of digitization around sourcing. A project manager, owner or a site super had to call or email a bunch of different suppliers, just to see what’s available, eating up more valuable jobsite time.

Three: the payment and approval process. “Most builders have 10 to 20 different supplier accounts,” says Bornstein. “It was an accounting nightmare for us.”

The vision for Toolbx was to take all three of these pain points and create a digital materials procurement platform that connects builders with their suppliers. “We do it in a transparent, digital way to give time back to the builder by making it fast and easy,” says Bornstein.

Supply chain visibility

The key was to provide visibility. “When you order from a traditional supplier you don’t know where the materials are, you don’t know when they’re going to show up and you often don’t get a confirmation when they ship,” says Bornstein. “If you’re a builder working on multiple jobsites, not having that visibility can cause a lot of friction.”

For a Toolbx user, all decisions get documented and streamlined within the app. You can add jobsites and add crew members with a few taps on a smartphone. Every order is GPS tracked. And you can place an order 24/7 from anywhere to get the materials to your jobsite anytime between 7 a.m. to 5 p.m. Payment is handled within the app and all your invoices are posted online for you, organized by jobsite.

Delivery within hours

The supplies and materials Toolbx sources run the gamut from hand and power tools to PVC pipe fittings and hardware to rebar, lumber, steel and concrete. “We have about 50,000 SKUs in our database today,” says Bornstein. “But as we go into new markets, we bring on more suppliers and continuously update those SKUs.”

Toolbx outsources its fleet of delivery vehicles and partners with Onfleet, a provider of last mile delivery management software to connect businesses, dispatchers, drivers and deliveries to end customers in real time.

Lumber, drywall, insulation, fencing, decking products and hardware are some of the most frequently ordered items on Toolbx. “The larger orders typically get scheduled well in advance,” says Bornstein.

For large orders, Toolbx will partner with different suppliers and connect the order to their system, so the builder knows they have this material coming from a specific supplier. Then it facilitates the direct delivery from the supplier, and it all gets tracked in the Toolbx app.

“In the markets that we operate in, we can do deliveries in two hours or less,” says Bornstein. “You can schedule your orders in one-hour time slots, but you also have the option to do four- hour or next-day time slots scheduled in advance. You can also place an order at 11 p.m. and have it show up at 8 a.m. the next day.”

marketplace for material suppliers

Toolbx doesn’t stock materials or products. It’s not a threat to retailers. Rather it partners with both big box stores and local specialty suppliers.

“The nice thing about it is that it is a symbiotic relationship,” says Bornstein. “We are driving revenue to them and helping those suppliers digitize as well. We’re not just building tools for the contractor, but we’re also building tools to help optimize suppliers, as well, because it works hand in hand. We’re trying to provide efficiency and productivity to both sides of the equation.”

The company does not charge users a platform fee, but rather adds a markup on items purchased through the app. There is also a delivery fee depending on distance and weight.

Contractors can also get a $99 monthly subscription that offers unlimited, free same-day deliveries and discounts on delivery upgrades and Pro pricing which gives subscription users up to 7% off on materials in the Toolbx catalog. Competitive delivery quotes are also available on bulk orders.

It says it also save customers money on bulk orders. Users who have a large order can send their materials list directly and they will get a competitive quote (using supplier partnerships) including delivery within 24 hours.

Toolbx is available now throughout Canada and is planning a rollout in the United States next year.

Did you miss our previous article…

https://constructionosa.org/?p=709

JLG’s 670SJ Boom Lift Levels Itself on Slopes Up to 10 Degrees

Wouldn’t it be great if every jobsite was graded smooth, compacted and level before you had to get on it with your boom lift? Yeah, right. Ain’t going to happen.

JLG has come up with the next best thing, the JLG 670SJ self-leveling boom lift, which can automatically level itself on slopes up to 10 degrees in any direction…while driving.

Under the machine, four independent axles, each controlled by smart hydraulic cylinders, enable each wheel to separately follow the contour of the terrain and stay in constant contact with the ground. This allows the machine to continuously self-level, without requiring operator inputs, and navigate uneven terrain while driving at height from one job to another without lowering the boom. It also reduces or eliminates the prep work — grading or building cribbing — required to level the work area so your lifts can get started first thing in the morning. Another time saver: there’s no need for the trial-and-error effort of repositioning to find a level work area.

The 670SJ offers three operating modes:

Self-leveling mode enables the machine to work at max height on slopes up to 10 degrees with full functionality.Travel mode can be used when the boom is stowed to move across the jobsite at faster speed.Shipping mode allows the entire machine to be lowered once it’s in position on a truck, reducing its travel height. >

As to capacity, the JLG 670SJ self-leveling boom lift offers a 73-foot work height and 57 feet of horizontal reach, with 550 pounds of unrestricted and 750 pounds of restricted load. It also features JLG’s automatic, single-sensor, load-sensing system with zero-load calibration. This keeps the machine within the allowable work envelope by limiting range, depending on the platform load.

Did you miss our previous article…

https://constructionosa.org/?p=706

Cat Sales, Revenues Increase 25% in Q3

Caterpillar reported a robust Q3 2021, saying it saw a 25% increase in sales and revenues over the same quarter last year.

Sales and revenues rose from $9.9 billion in 3Q 2020 to $12.4 billion this year, prompted by higher sales volume driven by end-user demand for equipment and services, the impact of changes in dealer inventories and favorable pricing. Dealers decreased inventories by $600 million during Q3 2020 compared with$300 million during the same quarter this year.

Cat also noted its operating profit for the quarter was $1.66 billion, an increase of 69% compared with the same period in 2020. This despite higher manufacturing costs because of higher variable labor, freight and material costs.

Construction Industries

Caterpillar’s Construction Industries Q3 2021 sales by geographic region.Caterpillar

Cat’s global construction industries segment saw a 30% year-over-year increase for the quarter, realizing $5.25 billion in total sales, an increase of $1.99 billion over Q3 2020.

The company’s North American construction markets increased by 36% year over year, driven by higher end-user demand from improving non-residential construction, continued strength in residential construction and dealer inventory changes.

The only geographical construction industries market to see a decrease was Cat’s Asia/Pacific region, due to lower sales volume and dealer inventory decreases, particularly in China.

“Our global team continues to execute our long-term strategy for profitable growth while working to mitigate supply chain challenges as we serve our customers,” says Jim Umpleby, chairman and CEO. “Our third-quarter results reflect higher sales and revenues across our three primary segments and in all regions.”

Did you miss our previous article…

https://constructionosa.org/?p=703

Colorado Contractor Faces $200,000 in Penalties for Trench Death

When rescue personnel arrived at a trench collapse on April 16, they found three workers trying to save a coworker who was stuck in mud and under water.

After a seven-hour operation involving 60 rescue personnel, the body of 50-year-old Luis M. Cortes-Correa was recovered.

His employer, Dunaway Excavating Inc. of Strasburg, Colorado, now faces $203,628 in proposed penalties for four violations, including not providing workers with cave-in protection and protection from accumulating water, according to the U.S. Occupational Safety and Health Administration.

The workers were connecting a sewer pipe between the main line and a home under construction in Johnstown, Colorado. The area has a high water table because of the nearby Big Thompson River. They were using a pump of some type at the bottom of the trench, so they could see the sewer main, according to the Loveland Fire Rescue Authority.

The trench was 16 feet deep, and 19 feet wide at the top. It narrowed to 11 feet at the bottom and had 2 feet of water in it, OSHA reported.

As water continued to flow into the bottom of the trench, the walls partially collapsed from the bottom. Water rushed in and covered a worker who also became trapped in the collapsed mud, the rescue authority said.

After they arrived, rescuers ordered the three construction workers out of the trench for fear of further collapse. The operation soon turned from rescue to recovery “due to the continued collapse threat and constant groundwater flow,” the rescue agency said.

Rescue workers were unable to stabilize the walls of the funnel-shaped trench as water continued to flow in. While vacuum trucks and pumps removed the water, construction equipment on site was used to try to recover the body. The operation also involved removing a natural-gas and power lines.

After the Loveland Fire Rescue Authority’s recovery operation, Battalion Chief Tim Smith urged contractors to use trench boxes and other protection for workers in trenches.

“It’s more time and effort,” Smith said, “but what they don’t see is the outcome if they don’t use these safety devices.”

Rescue personnel worked seven hours into the night April 16 in recovering the body of a worker who died in a trench collapse in Johnstown, Colorado.Ian Zahn, Loveland Fire Rescue Authority volunteer photographerThe coroner ruled that Cortes-Correa’s cause of death was mechanical asphyxia/drowning.

After an investigation, OSHA determined the trench had not been properly sloped, benched nor had any protective system in place, such as a trench box. It said the employer had not provided training to workers on recognizing cave-in and accumulated-water hazards.

OSHA also determined Dunaway had not provided a means for employees to safely get out of the trench. The two ladders did not extend at least 3 feet beyond the top of the trench, and one of the ladders was damaged.

Along with the $203,628 in proposed penalties, Dunaway was placed in OSHA’s Severe Violator Enforcement Program, “which concentrates resources on inspecting employers who have demonstrated indifference to their OSH Act obligations by committing willful, repeated, or failure-to-abate violations.”

“The threat of trench collapses makes excavation work among the most dangerous jobs in the construction industry,” says OSHA Area Director Amanda Kupper in Denver. “This worker’s life and family’s grief could have been spared if required precautions had been taken.”

Did you miss our previous article…

https://constructionosa.org/?p=700

Road Projects Feel the Pain of Congress’ Last-Minute Funding Extensions

Construction, engineering and transportation groups are frustrated by the House once again delaying a vote on the $1.2 trillion infrastructure bill and also having to enact another short-term extension of federal transportation funding.

“Repeated month-long extensions of the federal funding programs for transit, roads and bridges mean that cities and states cannot move forward with critical transportation projects,” says Tim Smith, executive director of the American Society of Civil Engineers.

On Thursday, a House vote on the Infrastructure Investment and Jobs Act was delayed after negotiations among Democrats broke down. The House did, however, extend transportation funding until December 3. The funding was set to expire October 31 after a previous 30-day extension.

Meanwhile, construction and related industry associations are becoming more frustrated, not only at the inability to pass the infrastructure bill but at leaving states in a lurch with last-minute, temporary extensions.

A recent survey of departments of transportation around the country revealed that many DOTs face uncertainty with planned road and bridge contruction projects because of the temporary extensions.

In the survey, conducted by the American Association of State Highway and Transportation Officials, the Kentucky Transportation Cabinet commented:

“Over the next four months, KYTC has over a quarter of a billion dollars in projects scheduled for construction lettings. Without the certainty of full federal-aid highway funding, many of these projects could be delayed until federal funds are in hand.”

The Alabama Department of Transportation reported that a lack of long-term funding would ripple through the state’s economy:

“The impacts of a short-term extension are not just project-related; it also increases labor, construction and material costs affecting ALDOT and its contractors, consultants, material suppliers and Alabama citizens who work for these businesses. Many of these businesses and employees are still struggling to recover from Covid-19-related effects, and the postponing of work a short-term extension generates is profound and unfortunate.”

Transportation funding almost expired

The Senate passed the Infrastructure Investment and Jobs Act in a bipartisan vote August 10.

But since it moved to the House, progressive Democrats have been using the bill as leverage to try to pass the Build Back Better Act. That bill started with a $3.5 trillion price tag that includes such things as pre-kindergarten, expanded health care coverage and environmental initiatives.

At the same time, almost every Republican in the House plans to vote against the infrastructure bill, despite 19 Republicans supporting it in the Senate. They call the infrastructure bill a “Trojan horse” to try to ram through the BBB Act.

As the political bickering and negotiations continue, state departments of transportation – and those who build roads and bridges – around the country were three days away from seeing federal transportation funding expire and 3,700 USDOT employees furloughed. That’s because a last-minute extension enacted earlier this month was set to end October 31.

“Legislators cannot continue granting extensions from month to month using funding estimates from the previous decade without causing uncertainty for workers and business owners in the communities they are elected to serve,” says National Asphalt Pavement Association President and CEO Audrey Copeland.

What’s next?

President Joe Biden and Democrats in the House and Senate continue to hammer out the details of the Build Back Better Act.

Biden scaled back the proposal Thursday from $3.5 trillion to $1.75 trillion in the hopes of satisfying moderate Democrats while also keeping some of his priorities and getting the infrastructure bill to his desk.

Progressive Democrats still want the House to vote on the BBB Act and the infrastructure bill together. They also say they need to see the text of the reduced BBB Act before voting on it.

Congress now faces a December 3 deadline for federal transportation funding. That’s also when the federal debt ceiling needs to have been extended, or the government could default on its debt.

Congress is expected to return to session Monday.

The Associated General Contractors of America’s CEO, Stephen E. Sandherr, called on progressive Democrats and Republican leadership to consider the infrastructure bill outside the lens of partisan politics and think of its impact on an economy still emerging from the pandemic-induced slowdown.

“It is extremely disappointing that some progressive Democrats and the Republican leadership would again delay passage of a much-needed infrastructure bill,” Sandherr said. “This legislation will provide investments that will make our fragile supply chains more efficient while providing a needed boost to economic growth and employment levels.”

Did you miss our previous article…

https://constructionosa.org/?p=697

Improve Excavation Efficiency 45% with Volvo/Topcon Precise Excavator Control

In the first stages of GPS-driven machine control, this technology enabled many contractors to park their motor graders and finish grade with a dozer. As GPS machine control migrated to excavators some even found it possible to finish grade complex contours with their digging machines.

Now Topcon and Volvo have taken steps to further enhance the precision and versatility of excavator machine control by combining Volvo Active Control on the Dig Assist with Topcon’s 3D-MC software on applicable Volvo excavators. And it’s all factory-installed and supported by Volvo dealers.

With the integration, Volvo Active Control automates the digging process and Topcon’s software syncs with the Volvo menus, allowing operators to customize how they want their automatic controls to function. The combined technologies make it easy to dig straight, perfectly on-grade trenches or carve complex elevations, shapes and contours automatically. The GPS-guided bucket stops when it reaches the designed grade, so you move the dirt only once and you never over dig and thus never have to recompact or regrade using an additional machine. According to Volvo, these features can improve excavation efficiency by as much as 45%.

Recent updates to Topcon’s 3D-MC software include over-the-air access to Sitelink3D, support for LandXML files, over-the-air remote support and a new graphical user interface. In addition to being 3D machine control capable, Volvo’s Active Control software supports auto-tilt features for tilt buckets and Steelwrist tiltrotators. It also offers several position limiting features for the bucket and boom such as return-to-dig (bucket recall) and automatic back grading. Volvo’s Boundary Limits package enables operators to automatically stop the swing motion at a set angle to assist in digging and truck loading. It also provides pre-set boom and bucket elevations and swing to avoid side or overhead obstacles.

For customers in North America, the integrated technology is offered on three models, the EC220E, EC250E and EC300E, with additional models to be added to the list in 2022. For customers in Europe, Oceania and Asia, Volvo Active Control is currently available on the Volvo EC220E, EC250E, EC300E and EC350E crawler excavators.

Did you miss our previous article…

https://constructionosa.org/?p=694

Hitachi Renames U.S. Subsidiary Following Deere Split

The U.S.-based subsidiary in charge of the manufacturing and sales of Hitachi brand wheel loaders in North America will now be known as Hitachi Construction Machinery Americas Inc.

Effective October 1, the name change comes on the heels of Hitachi and Deere announcing the dissolution of their joint venture for manufacturing excavators in North and South America.

Hitachi says the new name corresponds with its plans to establish an independent network of construction equipment sales and parts and services business operations in North, Central and South America. Starting in March, Hitachi will independently deploy new products, technologies and services in the regions.

The previous name, Hitachi Construction Machinery Loaders America, was established in 2017 after the company purchased KCM wheel loaders. HCMA will operate as a wholly-owned subsidiary of Hitachi Construction Machinery based in Japan.

Hitachi saw a significant bump in revenue following the dissolution of the Deere joint venture. The company posted a 31.3-percent increase in revenues for its second quarter (ending September 30, 2021), compared to the same period last year. In issuing its results, Hitachi said sales prices for the Americas were adjusted following the split, bringing the company’s adjusted operating income to 38,102 million yen (an increase of 248.3-percent year-on-year).

According to a company press release, Hitachi Construction Machinery will conduct a thorough review of the organizational structure of the Newnan, Georgia-based regional headquarters as it seeks to strengthen the position of the company and its promotion structures in the Americas.

The company plans to add staff to better respond to sales, service and regional market needs for all Hitachi Construction Machinery products, including wheel loaders, compact and construction-sized hydraulic excavators, ultra-large mining excavators, and mining dump trucks.

In Japan, Sonosuke Ishii, senior vice president and executive officer, president of the mining group, has also served as general manager of the America Business Division since October 1.

In the U.S., with the establishment of HCMA, Ishii has also been appointed chairman of the company. Masaaki Hirose, former chairman, has served as vice chairman, working together with Alan Quinn, managing director, to strengthen cooperation between Japan and the Americas.

The company also established Americas Business Expansion Support Office to support the regions through the Hitachi Construction Machinery Group.

Did you miss our previous article…

https://constructionosa.org/?p=691

Elon Musk’s 29-Mile Vegas Loop Under the Strip Wins Approval (Video)

Elon Musk’s Boring Company has won permit approval and a franchise agreement to build the Vegas Loop under the Las Vegas Strip.

The 29-mile underground transportation system would connect with the Las Vegas Convention Center Loop that opened in June. That .8-mile link transports convention center goers through tunnels in electric Teslas and is Musk’s first fully commercial operational tunnel.

The Vegas Loop would have 51 stations throughout the Strip and into Clark County and would have a capacity of 57,000 passengers per hour. The Clark County Commission approved a special-use permit October 20 for The Boring Company to apply for and receive building permits to build the tunnels, according to the Las Vegas Convention and Visitors Authority.

The commission also approved a franchise agreement with Boring that allows it to operate the Loop. Boring would pay to build the Loop and then collect fares from passengers. The commissions says no tax dollars would go toward funding the project. The franchise agreement also faces a vote by the Las Vegas City Council.

Along with the Strip, the Vegas Loop would connect to downtown, McCarran International Airport and Allegiant Stadium. The Boring Company says the goal is to eventually link Las Vegas and Los Angeles.

A map of the proposed route of the Vegas Loop to be built by Elon Musk’s Boring Company.The Boring CompanyBoring and Las Vegas convention center representatives hailed the Vegas Loop as a relief to the city’s traffic congestion and an easier way to get visitors to their destinations. An example provided by Boring says a trip from the convention center to Mandalay Bay, which can take up to 30 minutes, would be shaved to 3 minutes with the Loop.

“The Vegas Loop will be a game-changer for our visitors in moving them around our exciting destination quickly, conveniently and in an entertaining ‘Only Vegas’ way,” says Steve Hill, LVCVA president and CEO.

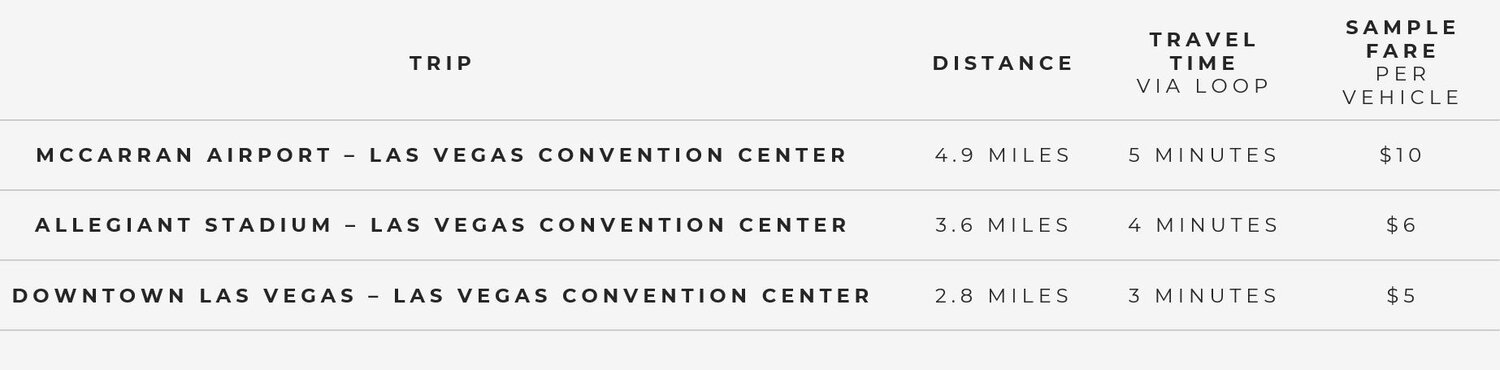

The electric Teslas would travel through the tunnel directly to a passenger’s destination station with no stops along the way, unlike a subway system. The Boring Company provided the following sample trips and fares:

Sample fares for the future Vegas Loop, which would be self-supporting.The Boring Company

Musk envisions the Teslas reaching speeds of up to 150 mph and being autonomously driven. High-occupancy automated electric Teslas are also planned that would hold up to 16 passengers with sitting and standing room.

The convention center Loop, which opened in June, consists of a mix of 62 Tesla Models 3 and X that have drivers and reach top speed of 40 mph, because of the tunnels’ short length. They can hold up to five passengers.

The convention center tunnels are 40 feet underground. Riders can travel across the convention center campus in 2 minutes versus a 25-minute walk. The Loop debuted at World of Concrete this year. It cost $52.5 million to build. It has a capacity of 4,400 passengers per hour and three stations.

Check out this video of the convention center Loop:

CMSBrowserComponents.load({ el: ‘#vue-1635441286480-229’, name: ‘OEmbed’, props: {“mountPoint”:”/__oembed”,”url”:”https://youtu.be/UIP0WQnQyps”,”attrs”:{“type”:”oembed”,”id”:”https://youtu.be/UIP0WQnQyps”,”element”:”aside”}}, hydrate: false });

Did you miss our previous article…

https://constructionosa.org/?p=687

Dig in Tight Spots with Komatsu’s New PC78US-11 Compact Excavator

Komatsu has introduced a new “tight tail swing” excavator well-suited for urban environments, confined spaces and crowded jobsites.

With its 68-horsepower engine, six work modes and swing radius under 5 feet, the PC78US-11 can handle precise digging, as well as large excavation tasks.

The 12-foot 2-inch boom has a greater raising angle and a short implement swing radius (6 feet 9 inches minimum), giving the PC78US-11 the ability to dig efficiently in a crowded space. At the rear, the tail swing radius measures just 4 feet 7 inches. Viewed from above, both the front and the rear corners of the superstructure are rounded, with the maximum cab extension over the tracks at just 9 inches.

For fast digging

Komatsu’s newest tight tail swing excavator is ideal for urban environments and confined spaces.Komatsu

Good operators like a quick machine, and Komastu’s faster boom up and swing speed increases productivity by 9%. To better match machine performance to the application, Komatsu arms the PC78US-11 with six work modes: power, economy, lifting, breaker, attachment-power, and attachment-economy.

For operators who prefer backhoe-style controls, a pattern change selector valve comes standard. The grading blade has a new moldboard profile to improve backfilling and grading efficiency. The PC78US-11 accepts buckets from 0.10 to 0.26 cubic yards.

Low maintenance demands

A new high-output 2.4-liter, Tier 4 Final engine gives you ground-level access to service points. The heavy-duty, high-pressure common rail fuel injection system and cooled exhaust gas recirculation (CEGR) achieve near complete combustion in cylinder to reduce emissions.

A Komatsu diesel oxidation catalyst removes exhaust soot and enables 100% passive regeneration without a diesel particulate filter or regular refills of diesel exhaust fluid. The no-DPF, no-DEF design translates into lower owning and operating costs, reduced maintenance and one less component to replace or worry about.

Komatsu’s compact engine makes room for a fan clutch system, allowing engine and hydraulic system tuning to reduce noise by a full decibel. Typical in-cab noise levels measure 71 decibels — about the same as a household vacuum cleaner. When engine cooling is not required, the viscous fan clutch reduces parasitic horsepower draw. Overall engine improvements boost fuel efficiency as much as 13%.

Cab comfort

The air-suspension seat has deep side supports and an adjustable backrest angle to support operators of all sizes. The cab comes with AM/FM radio with USB and Bluetooth technology.

Komatsu improved cab dampening by incorporating a spring and a longer stroke on the viscous cab mounts. This, plus a beefed up deck, reduces vibration to the operator to keep him or her more comfortable and focused throughout the day. The sealed and pressurized cab keeps dust out and automatically maintains temperatures to the level set on the monitor.

A sliding cab door makes access easier, especially when you’re entering or exiting the excavator up against a wall or in confined spaces. The cab is ROPS certified and satisfies the requirements of ISO OPG Top Guard Level 1 for falling objects.

Crowded jobsites often restrict sight lines, so Komatsu added a 7-inch LCD display to the PC78US-11 with a standard rearview camera image. LED lights provide nighttime illumination of the jobsite.

The variable displacement/axial piston hydraulics for the boom, arm, bucket, swing and travel circuits offer a maximum flow of 44.4 gallons per minute. Relief-valve settings for implement circuits are rated at 4,264 psi. The auxiliary circuits put out 36.5 gpm/3,830 psi (two way) and 21.1 gpm/2,490 psi (one way).

For travel and trailer considerations, the PC78US-11 has an operating weight of 17,747 pounds.

Did you miss our previous article…

https://constructionosa.org/?p=684