Home » Construction Management (Page 4)

Category Archives: Construction Management

Thunder Creek’s Intros Service and Lube Upfit for Medium-Duty Trucks, No CDL or HAZMAT Required

Thunder Creek Equipment’s new Service and Lube Upfit (SLU) for medium-duty truck bodies doesn’t require drivers to have CDL or HAZMAT certifications, saving customers from increased insurance costs, and the cost of hiring highly sought after CDL drivers.

The new product, launched at The Utility Expo in Louisville, Kentucky, allows for customization much like the company’s Service and Lube Trailer, but with the nimbleness of a medium-duty service body.

Smaller than a traditional service and lube truck, the SLU can be installed on a Ford F-550 or Ram 5500 chassis. “Dealers, rental companies and construction companies are having a hard time hiring technicians and CDL drivers. Plus, they’re finding out they’re not being profitable sending out a $300,000 truck with a $40-an-hour employee to do a simple oil change,” said Steven Ile, territory sales manager, Thunder Creek Equipment. “This affords them the ability to put anybody with a valid driver’s license and basic technical skills in the truck and go.”

A built-in VMAC air compressor powers the entire SLU pneumatic pumping system. The tanks provide a total capacity of 690 gallons and are configurable in 115-, 55-, and 25-gallon tanks, depending on a customer’s fleet maintenance needs.

Fluids supported include fresh oil, reclaimed oil, grease, antifreeze, reclaimed antifreeze, high flow oil, diesel fuel and diesel exhaust fluid. “It is 100 percent customizable,” said Ile. “If one customer needs 345 gallons of fresh oil and 345 gallons of waste oil because they’re only changing oil, we can do that. If the next customer is running Deere, CAT and Komatsu equipment and needs three different spec oils, we can break that up into multiple tanks and give them more fluids.”

All fluid maintenance systems are plumbed into the truck’s new Utility Box, which features a streamlined control panel. The control panel is color coded to match the nozzles and hoses, making it easy to use for operators and reduce training. The SLU also features ample storage for filters and tools.

Each SLU is built to order. Customers can purchase the Service and Lube Upfit via select dealers or directly from Thunder Creek Equipment.

Contractors Get First Glimpse of Deere Electric 310 X-Tier Backhoe (Video)

Product details are still sketchy after all, it’s still a test machine but John Deere used the Utility Expo to strut out its electric backhoe, the 310 X-tier E-Power, now in real-world testing with utility client National Grid.

“The battery electric technology on the 310 X-tier is one way we’re going to give leading-edge performance with innovative technology,” says Justin Steger, Deere solutions marketing manager. “It is geared toward customers that have stated carbon emissions-reduction goals.”

Throughout the spring and summer, National Grid used the machine to perform a variety of jobs, including trenching, loading, digging, backfilling and using a breaker, says Brian Hennings, Deere product manager, speaking to Equipment World. Up next: cold-weather tests.

The “X-tier” identifies that it has a unique power train, says Hennings. “If we eventually do come out in the marketplace and things look very positive — the model would be offered as a 310 X.”

The placard next to the 310 X-tier at the Utility Expo said the machine represented an “early Phase 1 development in clean-energy solutions,” the same language Deere used in its January announcement that it was testing the machine. Deere will head into Phase 2 testing next year, Hennings says, and targeting energy consumption by specific components. “We want to offer at least an 8- to 10-hour composite runtime,” he says.

“We’re very early in this journey, and it’s going to take many iterations to meet customer expectations,” Hennings says, noting that even retaining the top 25 mph travel speed can consume a great deal of power. “It’s going to be more a matter of years instead of a matter of months.”

The 310 X-tier is positioned in direct comparison with the Deere 310L. Deere knows the electric unit will be compared with the runtime of the diesel unit, which has a 34-gallon tank and typically provides more than a day’s worth of work. One positive for the electric machine: it has an outside-machine decibel level of 75 while the 310L runs at 89 decibels. “It doesn’t sound like a lot on paper, but it’s not as loud as my dishwasher,” Steger says.

Jordanne Waldschmidt, chief editor of Equipment World, caught up with Joe Dietz, the chief technology officer at excavation contractor Bob Dietz & Sons, New Paltz, New York, at the show. Dietz and his two brothers also serve as ambassadors for Deere, sharing their passion for the brand on social media. Here he gives his impressions after operating the 310X-tier for the first time:

CMSBrowserComponents.load({ el: ‘#vue-1633972535383-57’, name: ‘OEmbed’, props: {“mountPoint”:”/__oembed”,”url”:”https://youtu.be/Gf25ST98g6Y”,”attrs”:{“type”:”oembed”,”id”:”https://youtu.be/Gf25ST98g6Y”,”element”:”aside”}}, hydrate: false });

Hennings says utility companies, such as National Grid, along with municipalities working under emission mandates, are likely to be first adaptors of the 310 X-tier when it comes to market.

What we know now

John Deere

As mentioned, Deere compares the 310 X-tier with the diesel-powered 310L. It has a net peak power of 75 kilowatts (equivalent to 100 horsepower) at 1,600 rpm. The placard at the Utility Show posted 310 X-tier specs in line with those of the 310L:

14-foot 1-inch max dig depth.6,602-pound loader lifting capacity. 6,992-pound crowd cylinder digging force. 22.8 mph max travel speed.

One noticeable difference: the 310L has a listed operating weight of 14,669 pounds; for the 310 X-tier that gets bumped up to 16,119 pounds.

But again, these are just Phase 1 specs. “There will likely be many changes in the specs before it’s available for sale,” Hennings says.

John Deere announced in January that it had partnered with energy company National Grid an electric, natural gas and clean energy company serving more than 20 million customers in the Northeast to pioneer the machine.

At the time, Jason Daly, Deere global director, production systems, technology and marketing, called the project “another stepping stone in our backhoe innovation journey.” Adds Hennings: “This is an exciting project for the Deere backhoe design team.”

Did you miss our previous article…

https://constructionosa.org/?p=533

Diesel Prices Jump as Crude Oil Hits Highest Price Since 2014

Increased demand amid the easing of the pandemic and OPEC+ supply limitations have caused the price of diesel to jump 10.5 cents in the past week. The average retail price of a gallon of on-highway diesel soared to $3.47 during the week of October 4, according to the U.S. Department of Energy’s Energy Information Administration. That’s $1.08 higher than just one year ago.

The nation’s most expensive diesel on average is in California at $4.369, while the least expensive diesel on average is $3.203 a gallon in the Gulf Coast. The Midwest region saw the nation’s highest one-week increase at 10.4 cents. The smallest one-week increase was 3.0 cents in California.

The Biden administration has urged OPEC+ to increase production and is considering releasing crude oil reserves to cool prices. U.S. West Texas Intermediate crude oil hit its highest price since 2014 at $81.06 per barrel. Crude oil accounts for 49%t of the cost of a gallon of diesel.

Price increases this fall were also impacted by storm damage. Several refineries in Louisiana are still preparing to restart after flooding and power outages caused by Hurricane Ida. Louisiana’s 17 oil refineries account for nearly one-fifth of the nation’s refining capacity and can process about 3.4 million barrels of crude oil per day, says the U.S. Energy Information Administration.

Complete diesel price information is available on EIA’s website.

Diesel prices are up more than $1 per gallon compared to one year ago.U.S. Energy Information Administration

Did you miss our previous article…

https://constructionosa.org/?p=520

From Brooms to Blowers, 11 Attachments for Clearing Snow

Winter weather is close at hand, so it’s time to start thinking about snow-clearing equipment.

Contractors have a variety of attachments to choose from to equip their construction equipment or pickup trucks to remove snow and ice from roads, parking lots and other surfaces.

Here are 11 attachments to consider:

Bobcat’s hydraulically driven angle broom attachment (pictured above) can handle quick cleanup jobs without damaging pavement surfaces. The bristles’ waved design creates a cleaner path and can sweep more snow or debris in one pass. Reverse bristle rotation is available on the 68- and 84-inch angle brooms for sweeping leaves, snow and debris away from corners, curbs, buildings and obstacles. The standard orange heavy-duty bristles are designed for longer life and better visibility. The attachment is available for Bobcat’s M and R series compact track loaders and skid steers and Bobcat Toolcats.

Doosan snow pusherDoosanDoosan’s bucket-mounted snow pusher attachment is designed for the company’s 13- to 20-metric-ton wheel loaders and toolcarriers. The attachment comes in two versions: 12 feet wide at 2,200 pounds and 14 feet wide at 2,400 pounds. The pusher is designed to be an alternative to buckets and traditional plowing for clearing parking lots and roads. Features include a 47-inch moldboard for high-capacity snow removal, a 1.5-inch rubber cutting edge to protect surfaces, high-grade steel skid shoes, a 12-inch push beam and three bucket-mount support tubes to help keep the snow pusher rigid.

Fisher Storm Boxx snow pusherFisherFisher made its Storm Boxx pusher plows for large construction equipment, such as wheel loaders and backhoes. Models are available at 12, 14 or 16 feet wide. A two-piece steel trip edge is designed to deliver a cleaner scrape of hardpacked snow and ice. It also protects the operator and equipment when hitting hidden obstacles. Floating attachment plates allow side-to-side movement and smooth out bumps, keeping the pusher in continuous contact with the surface. It is also designed to be easily attached to various equipment.

Hilltip salt spreaderHilltipHilltip’s new IceStriker 2000-3300 SSA/SSC stainless-steel salt spreaders are designed for three-quarter-ton trucks. The device can spread bulk sand and gravel, bulk/bag salt, sand-salt mixes and fertilizers. It is offered in three sizes: 2, 2.65 and 3.3 cubic yards. The stainless steel wards off corrosion, and Hilltip also immerses its hoppers in an acid bath to ensure corrosion-free welds and surfaces. An inverted “V” with a vibrator helps prevent bridging. The stainless-steel flip-up chute is designed to spread salt in environments with high humidity, and a tarp kit helps keep spreading materials dry.

HitchDoc hydraulic snow blowerHitchDocHitchDoc’s all hydraulic snow blower is designed to reduce your carbon footprint. The company has eliminated the diesel engine, crankcase, shear pin and air filter, as well as the need for diesel exhaust fluid. The hydraulic blower is quieter and offers better visibility and balance. It is 9 feet wide and weighs 5,200 pounds. It is designed for wheel loaders of 2 to 4 cubic yards equipped with hydrostatic transmissions.

JCB Snow BlowerJCBThe JCB snow blower range features a two-stage design with the ability to throw snow 25 to 40 feet. A poly-lined chute and deflector can be adjusted to direct the snow discharge. The 25-inch standard flow shroud openings quickly dispense with high volumes of snow. The direct drive hydraulic motor design reduces the number of moving components for less wear and longer life. The blower includes adjustable skid shoes, a bolt-on replaceable wear-resistant tapered steel edge and quick release coupling. It is available in widths of 60, 72, 78 and 84 inches in either standard or high flow.

Pettibone SpeedSwing 445F with snowblowerPettibonePettibone’s Speed Swing 445F rail crane is now available with a CreepDrive system from Poclain Hydraulics that allows it to run high-flow attachments like snow blowers and power brooms at slower travel speeds on or off the rails. The CreepDrive can deliver up to 33 gallons per minute of hydraulic flow. It comes with a display interface for controlling rpms and an integrated rocker pedal for traveling the machine forward and in reverse up to 2 mph. The Speed Swing 445F provides 180-degree boom rotation and has a spacious, climate-controlled operator cab.

SnowEx heavy-duty snowplowSnowExSnowEx’s heavy-duty straight-blade snowplow gives skid steers commercial-contractor performance. It is available in four blade widths. The plow is built with a formed base channel for extra durability. Six vertical ribs, two angled Power Ribs and a quad design provide added torsional strength to prevent blade twisting. The A-frame is constructed of tubular steel to handle the toughest jobs.

Virnig picukp broom with water tankVirnigVirnig’s Internal Water Tank Broom for skid steers controls dust as you sweep. The protected 55-gallon tank behind the bucket provides 35 minutes of continuous runtime. The translucent tank has capacity indicators so water level can be viewed by the operator while in the cab. The guarded adjustable valve regulates water pressure to the nozzles. The broom is available in 72 or 84 inches. Features on the broom include a recessed and guarded direct drive motor, HD bucket with wear bars, bolt-on edge, oversized 2-inch bearing, poly/wire bristles and pin adjustment system.

Western’s Prodigy Skid Steer SnowplowWesternThe Prodigy snowplow from Western features wings that automatically move with no additional wiring or controls. It has a universal skid-steer mounting plate. Once the pins are engaged, the plow is ready. The plow uses the onboard hydraulics system of the skid steer to lift and lower the blade. An oscillating mount that provides 6 degrees of total side-to-side oscillation is optional to improve scrape and cutting-edge wear while reducing damage to the terrain.

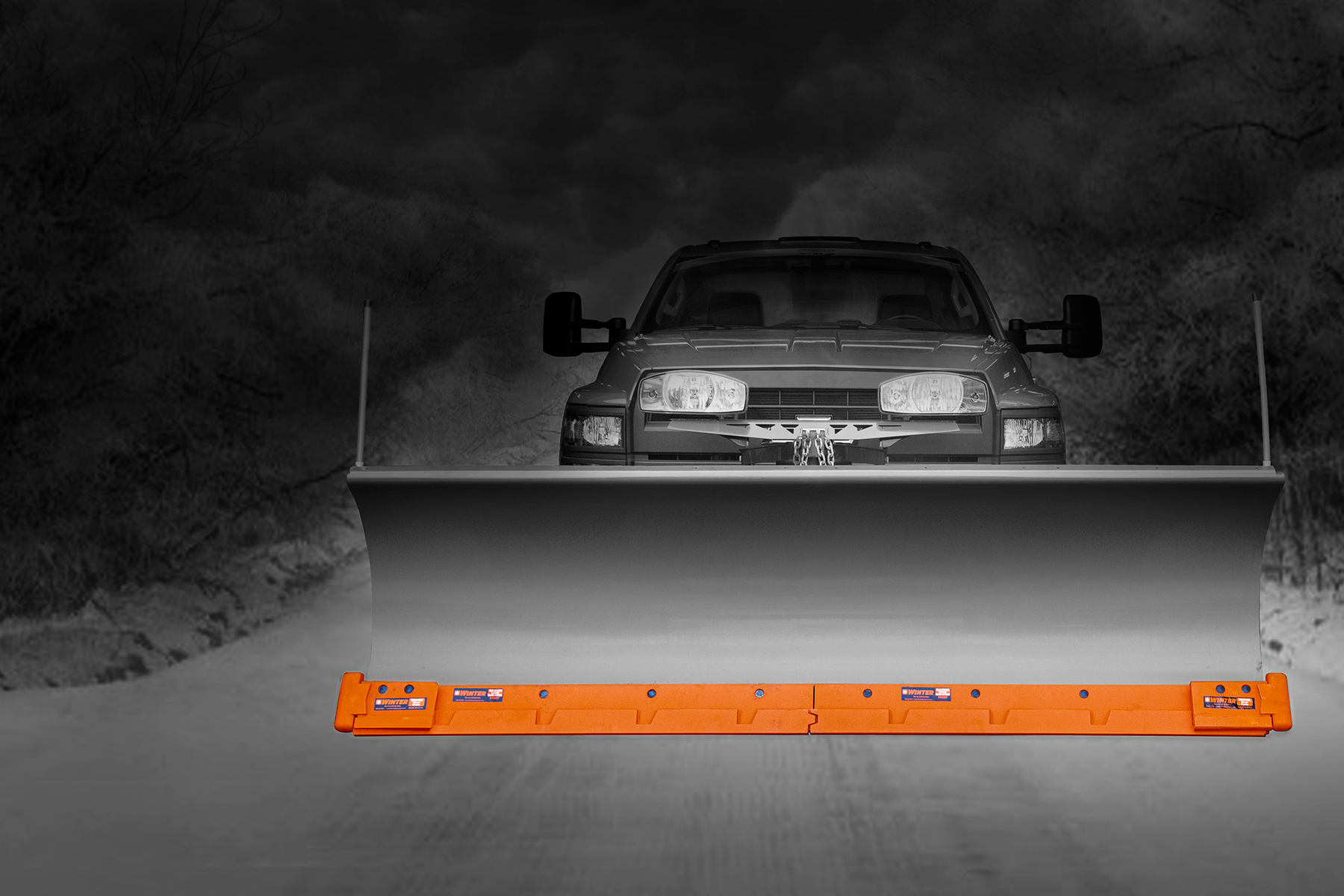

Winter Equipment Razor Arrow snow bladeWinter EquipmentWinter Equipment’s Razor Arrow Straight Blade System is designed to give Western Pro Plus plows longer blade life and improve cutting. It features two, 4-1/2-foot Razor blade sections, two Plow Guard Juniors and grade 8 hardware. The two Plow Guard Juniors prevent uneven and premature wear on the plow’s wear bar. The Razor Arrow system includes a two-piece, pre-welded blade with 5/8-inch abrasion-resistant cover plates. The cover plates are welded to a tungsten carbide insert cutting edge for increased wear life and surface footprint. Built-in wear indicators help to track wear life.

Did you miss our previous article…

https://constructionosa.org/?p=468

Industry Roundup: National Equipment Dealers buys Richardson

National Equipment Dealers (NED) has bought Richardson Service 1991, expanding its organization in South Carolina.

Based in Conway, South Carolina, Richardson specializes in construction, forestry and compact equipment and will now represent Hyundai Construction Equipment, Manitou, Sakai, Yanmar and Bell.

The former Richardson branch will be the first location among NED companies renamed as NED. Over the coming months, NED will rebrand the remaining MAY-RHI, Earthmovers Construction Equipment and Four Seasons branches to NED.

Through Richardson, NED gains the Berko, CMI and Prinoth lines. The entire Richardson team will remain with NED.

F&W adds Ransome Attachments

Pictured are (from left): Eric Ransome and Barbara Freund of Ransome Attachments, and Matt Valentine and Mark Laigle of F&W.Ransome Attachments

F&W Equipment has added the complete line of attachments offered by Ransome Attachments, including its Exac-One Mini Mower and Black Splitter S2 800 Cone Splitter.

F&W also offers Kubota compact and mid-size farm and landscaping equipment, Doosan excavators, wheel loaders and compact equipment, as well as other specialty equipment.

Maverick joins Morbark

Maverick Environmental Equipment has been named a Morbark Industrial Products dealer for Ohio, Indiana, Kentucky and western West Virginia. Maverick has locations in Newbury and Bremen, Ohio, with a focus on aggregate processing, waste recycling, forestry and biomass.

H&E completes crane sale

H&E Equipment Services has completed the $130 million cash sale of its crane business to Manitowoc. H&E says it will use the funds for facilities expansion, rental fleet investment and general corporate purposes.

“We believe our transition to a pure rental business strategy should result in improved revenues and margins through the industry cycle,” says Brad Barber, H&E CEO.

H&E also sold two earthmoving distribution branches in Arkansas, and will remain a distributor of earthmoving equipment in Louisiana. The company now has 101 branch locations in 24 states.

SMH Group adds Wood’s CRW

Wood’s CRW is now a dealer for Atlas material handlers, owned by SMH Group US. The Atlas line includes mobile industrial machines and industrial tracked machines for the scrap, wood and recycling markets, among others.

Based in Williston, Vermont, Wood’s CRW has four locations with coverage in all or part of eight states. It offers Volvo Construction Equipment, Link-Belt cranes and excavators, National cranes and Mecalac product lines.

15 Proven Ways To Recruit Construction Dealer Techs

The ever-present dealer technician shortage had us thinking it might be a good time to revisit some of the best construction equipment tech recruiting tips we’ve received from dealers and rental companies.

1.Go to where the gearheads hang out. This can include truck mud-runs and local motorsports events. Sponsor an involved employee or a car and invite current employees to attend think of them as your ambassadors. While you might not find a trained diesel tech in the audience, many of the attendees will have a mechanical interest. Your sponsorship may give you access to this community plus build retention among the techs you already have.

2. Think beyond just out of high school. Those fresh-faced 18-year-olds may not be your only hope. Some argue that those with more years and more life experiences may be also be prime targets, especially if they’re only making $16 an hour in an Amazon warehouse. Those who have started families may be receptive if you lay out a career path and a smart diesel tech these days most assuredly has a career path.

3. Get good at social media. Yes, this is obvious, but do you really practice it? Consistent posting is the name of the game. Create a social media plan and execute it. Put up regular posts of your employee’s jobs, milestones and success stories, and encourage them to do the same. If a technician completes a rebuild on a big engine, for instance, the selfie they take might detail how they overcame the challenge. His or her share full of the pride of accomplishment about work done at your company could in turn gain an audience. And it will remind people that you’re a great employer.

4. But don’t dismiss the tried and true. Traditional methods can still hold sway, including help-wanted signs on company property or trucks, word of mouth and employee referrals. Many employers swear by the referrals they get from current employees because employees know a bad referral will reflect poorly on them. And always ask job candidates how they heard about your company and keep track of which methods work.

5. Be aware of the digital tools available to you. Find out how you can target an online audience. Look into geotargeting and targeted data sets and know what works in terms of setting up your online ads and landing page(s). You can target people on Facebook, job boards and through search-engine marketing. And be transparent in your messaging. This includes being direct about base pay, hiring and relocation bonuses as well as highlighting company culture. Have a timely lead followup in place; ideally respond within 5 minutes by phone after a lead comes through.

6. Make sure you’re inviting to women and minorities. Realize that diversity inclusion and workforce development are closely intertwined. When you do a bad job at tapping into diverse groups, you are more likely to have a workforce problem. Explore local groups that can help you reach out to specific communities.

7. Grow your own. It’s difficult to hire off the street and there are not enough tech school grads to fill the need. One neglected area may be right in your back yard. Make sure your own techs know about the opportunities you are bragging about to the outside world and encourage them to advance.

8. Up the ante. Sometimes it is a money/benefits game. Assess what you’re offering compared with all local employers, not just the ones who are your direct competitors. One rental company offers to match a certain percentage of an employee’s student loan payments up to $30,000 — and they don’t require a period of employment before the reimbursements begin.

9. Have a recruiting plan. If you’re proactive with your recruiting strategy you won’t have to hire out of desperation. And don’t stop. Actively recruit even if your shop is currently at capacity. Set a goal of tech interviews to be accomplished in a certain time period. Consistently evaluate what works and what doesn’t.

10. Celebrate incoming tech interns. Several tech schools and dealerships have set up “signing day” events such as those conducted for celebrated college athletes. It helps solidify the intern’s commitment and gives them the vision and knowledge they have an official spot.

11. Emphasize the career runway. Candidates have to earn the next rung on the ladder and there are going to be long hours, hard work, grease and dirt involved. New hires are not going to get a $70,000 job right out of tech school. But let them know there is a career runway and there are many paths up from the shop floor. These include the emerging technical expert who guides customers on the best way to employ today’s machine control solutions.

12. Hire a hero. The Reserves and National Guard are sweet spots for recruiting because their units are all locally based. These “weekend warriors” pull one weekend of active duty service a month and one two-week mission a year. The rest of the time they are civilians. While not all Reserve or Guard units have mechanics or technicians a high percentage have motor pools. In addition to a scholarship, one rental company pays the gap between discharge and when the G.I. Bill benefits take effect, providing around $1,200 to help cover living expenses. And be sure to spend time at any recruiting and career fairs at military bases in your area.

13. Take back the high schools. Don’t assume that local guidance counselors know that there are high-paying jobs that go unfilled in their local area. One company wrote to 3,500 guidance counselors and educators in its state, and received several “we didn’t know” responses. One dealer goes on more than 80 high school visits a years to connect with students in three states. Another dealer makes presentations on how to research and choose a career that’s only tangentially about diesel tech careers. Educate the people who are at your back door.

14. Don’t forget the parents. Take a cue from the recent U.S. Army ad campaign you’re looking for a few good parents, ones that see the open technician field as a great opportunity. Host an event at your shop and invite the parents along with the students. Have your techs show what it’s like to work on heavy equipment. Recruiting talent is no different than a college football coach coming into someone’s living room and telling the parents that when they come to you, you’ll make sure they do well.

15. Never stop recruiting. Adopt some tactics floating in automotive circles. Have a business card with your elevator pitch on it, outlining the top three reasons why people should work for you. Or make it simple: show a piece of construction equipment with text that reads, “Your next job here” with your contact info. Hand them out with a comment such as, “I’m Joe and I hire diesel technicians.”

Did you miss our previous article…

https://constructionosa.org/?p=456

Case Unleashes Industry’s Largest Compact Track Loader, the TV620B

With an operating capacity of 16,100 pounds, Case’s newest compact track loader is now the largest in the industry, designed for size and power for residential construction and land clearing. The company unveiled its new CTL at The Utility Expo in Louisville, Kentucky.

Powered by a 114-horsepower engine, the TV620B provides 12,907 pounds of loader breakout force and 12,907 pounds of bucket breakout force. It has a rated operating capacity of 6,200 pounds.

Built on an extra-large frame, Case says, the TV620B isn’t just the big brother of the TV450; the machine was redesigned from the ground up.

“We talked to a lot of customers who were running larger CTLs and asked them what they’d like to see,” said George MacIntryre, product manager, Case. “We really focused on certain areas making sure that the frame was robust and could stand up to harsh conditions. A piston pump comes standard on this model giving customers the flow and pressure ratings they need to run big attachments. Lastly, we focused on the performance of the loader to be able to dump into high-sided trucks.”

More features now come standard on the TV620B, including:

Electro-hydraulic controlsHigh-flow hydraulicsAutomatic Ride Control and one-way self-levelingA programmable hydraulically reversing fanLED lightsThe new SiteConnect ModuleOne year of Case SiteWatch telematics

Electro-hydraulic controls allow the operator to set total machine responsiveness to low, moderate or aggressive, or independently set tilt, lift and drive speed, as well as loader arm and drive control to adjust to the demands of the job. This is set through the LCD multi-function display in the cab, which also comes standard, Case says.

“We are giving the operator more precise and intuitive control than they’ve ever had in a Case CTL and making the machine as simple to operate for as broad a range of applications as possible,” said MacIntyre.

High-flow auxiliary hydraulics and enhanced high-flow hydraulics are available options, delivering 3,450 psi and 4,100 psi, respectively, at 41.6 gallons per minute, making mulching heads, cold planers and grading blades ideal companions for this machine. An enhanced hydraulic cooling system maximizes uptime when using high-powered attachments. The TV620B also offers a selection of buckets, including a heavy-duty 84-inch, 1.25-cubic-yard bucket with SmartFit teeth.

One-way self-leveling and automatic ride control with adjustable speed settings reduce material spillage and deliver a smoother ride. Operators can adjust the foot pedal to serve one of three functions — accelerator (traditional acceleration), trans (reduces drive speed but retains rpm for loader arm functions), or decel (traditional deceleration).

The beefed-up undercarriage on the TV620B takes a nod from Case’s 650M dozer. “It’s much heavier-duty than the size class down from this,” said MacIntyre. “The idler ceiling on the TV620B is similar to the 650M dozer. The dozer components are a little bit larger than what we have on the CTL, but it’s really just a downsized version of what we have on the very reliable Case dozers.” Additionally, the 17.7-inch rubber tracks allow for minimal ground disturbance (6.1 psi) and enhanced performance on improved surfaces.

With a maximum dump height of 39 inches and 140.2-inch hinge pin height, the machine is well-suited for loading trucks. But MacIntyre says the loader arms will also look different from previous Case models. “We’ve gone to a straight-in-line loader arm linkage, giving great visibility down to the coupler and bucket area. It also allows the cab to be tipped forward with the loader arms in the down position to get even better access to all the components that are underneath the cab.”

Inside the cab, the TV620B features 360-degree visibility and an 8-inch split-screen display that simultaneously shows both the rearview camera and equipment information. A cab-wide rearview mirror gives visibility to the back of the machine. Large windows provide visibility to the front of the machine down to the attachments and optimal sight lines to the sides and rear of the machine.

Ground-level maintenance points allow for easy access to critical components. “The rear of the machine features an extra-large engine compartment so the components are easily accessible for daily checks,” said MacIntyre. “Our battery is located in a separate panel with the battery and master disconnect switch. It’s very easy to access – you don’t need to open up the rear hood for that.”

A combination of cooled exhaust gas recirculation (CEGR), diesel oxidation catalyst (DOC) and selective catalytic reduction (SCR) technologies enables the machine to meet emissions standards. The TV620B features no diesel particulate filter (DPF) and requires no regeneration, reducing downtime. An adjustable hydraulically reversing fan minimizes the buildup of debris in the engine compartment.

Production of the TV620B is underway, and customers can expect to see it at dealers in Q4 2021.

Quick Specs

Operating Weight: 16,100 pounds

Engine Horsepower: 114

Rated Operating Capacity (50 percent tipping load): 6,200 pounds

Rated Operating Capacity (35 percent tipping load): 4,340 pounds

Hinge Pin Height: 140.2 inches

Reach at Maximum Dump Height: 39 inches

Loader Breakout Force: 12,084 pounds

Bucket Breakout Force: 12,907 pounds

High-Flow Auxiliary Hydraulics: 41.6 gallons per minute at 3,450 psi; 83.7 hydraulic horsepower

Enhanced High-Flow Auxiliary Hydraulics: 41.6 gallons per minute at 4,100 psi; 99.5 hydraulic horsepower

Did you miss our previous article…

https://constructionosa.org/?p=444

List: Construction & Building Simulator Games | ONE-KEY Blog

In this publication, when it comes to construction design, we typically discuss innovative approaches like design-build, prefabricated construction, and lean construction principles, among other topics.

![]()

Did you miss our previous article…

https://constructionosa.org/?p=440

12 Road Projects Named Finalists for America’s Transportation Awards

After months of regional competitions, 12 road construction projects have been chosen as finalists for America’s Transportation Awards.

The awards, sponsored by the American Association of State Highway and Transportation Officials, include projects in Arizona, Delaware, Florida, Indiana, Kansas, Kentucky, New Jersey, North Carolina, Oregon, Pennsylvania, South Carolina and Utah. Along with AASHTO, the U.S. Chamber of Commerce and AAA sponsor the awards program.

“This competition recognizes just a few examples that highlight the ways in which state DOTs are improving quality of life and economic vitality of our communities, saving time and money through new innovations and technologies, and making better use of assets already in place,” says Jim Tymon, AASHTO executive director.

The grand prize and People’s Choice winners will be announced October 26. Each winner receives $10,000 cash to donate to the charity of its choice. The competition evaluates projects in three categories: Quality of Life/Community Development; Best Use of Technology & Innovation; and Operations Excellence.

Finalists are also categorized by project size: small (projects costing up to $25 million); medium (projects costing between $26 million to $200 million); and large (projects costing more than $200 million).

Here are the 12 finalists:

Kentucky Transportation Cabinet – Brent Spence Bridge Emergency Repair Project (Operations Excellence, Small project group) (Photo above.)

Safety for drivers, cyclists and pedestrians was improved with the $13.9 million widening of the Fourth Street Bridge over Interstate 40 in Flagstaff, Arizona.Arizona Department of TransportationArizona DOT – Fourth Street Bridge over Interstate 40 (Quality of Life/Community Development, Medium project group)

The Delaware Department of Transportation alleviated traffic congestion and created more transportation options for a Wilmington community by constructing the $82 million Senator Margaret Rose Henry Bridge.Delaware DOTDelaware DOT – Margaret Rose Henry Bridge and Approach Roads (Operations Excellence, Medium project group)

The Florida DOT deployed a SMART Work Zone System that included a temporary traffic signal, three closed circuit cameras and nine Bluetooth devices on its project to improve the Cow Key Bridge.Florida Department of TransportationFlorida DOT – Leveraging Innovation: How FDOT Transformed the Gateway to Florida Keys (Best Use of Technology & Innovation, Small project group)

The Indiana Department of Transportation opened the Grand Valley Boulevard Bridge on June 15, 2020, in Martinsville. Replacing a section of four-lane State Road 37, the bridge gives drivers and pedestrians a safe connection to neighborhoods, schools and businesses.Indiana Department of TransportationIndiana DOT – Grand Valley Boulevard Bridge (Quality of Life/Community Development, Small project group)

Originally designed as a toll road in the 1960s but toll booths were never installed, the Turner Diagonal Interchange in Kansas City had three miles of obsolete and hazardous ramps. The Kansas Department of Transportation’s $30.3 million project increased safety and economic development.Kansas DOTKansas DOT – Turner Diagonal: Partnering for Growth (Operations Excellence, Medium project group)

The $25 million Route 1 Permanent Hard Shoulder Running Project overseen by the New Jersey Department of Transportation improved safety, increased emergency access, increased capacity and travel reliability, and cut commute times by up to 50 percent.New Jersey DOTNew Jersey DOT – Route 1 Permanent Hard Shoulder Running Project (Operations Excellence, Small project group)

The $101.6 million Salem Parkway improvement project in Winston-Salem, North Carolina. The project included 10 bridge replacements, two new pedestrian bridges, a walking and biking path and extended sidewalks.NCDOTNorth Carolina DOT – Reconstruction of Salem Parkway (U.S. 421/I-40 Business) (Quality of Life/Community Development, Medium project group)

Oregon Department of Transportation developed a $15.6 million automated system that posts real-time weather, traffic flow and surface condition readings on digital billboards on Interstate 84 in northeastern Oregon.Oregon DOTOregon DOT – I-84 Snow Zone Safety Improvement Project (Operations Excellence, Small project group)

To improve accessibility and safety for motorists, bicyclists, boaters and pedestrians along SR 381, the Pennsylvania Department of Transportation launched a $12.8 million multimodal gateway project at Ohiopyle State Park.PennDOTPennsylvania DOT – Ohiopyle Multimodal Gateway (Quality of Life/Community Development, Small project group)

This stretch of scenic S.C. 61 in the Charleston area underwent a $4.4 million improvement project to add new lanes and widen shoulders while reducing the number of trees cut.SCDOTSouth Carolina DOT – C. 61 Phase 1 (Rural Road Safety Program) (Operations Excellence, Small project group)

The Utah Department of Transportation completed a $415 million project that widened I-15 to six lanes in each direction, reconfigured two interchanges, replaced 15 bridges, built a new bridge, and created a new flyover ramp to address traffic congestion in rapidly growing Lehi.Utah Department of TransportationUtah DOT – I-15; Lehi Main to S.R. 92, Technology Corridor (Quality of Life/Community Development, Large project group)

An independent panel of transportation experts will choose the Grand Prize winner, while the public will select the People’s Choice Award winner through online voting weighted to each state’s population, AASHTO says.

The online voting ends at 11:59 p.m. October 25. Votes can be cast at AmericasTransportationAwards.org.

AASHTO will announce the winners during its Annual Meeting October 26-29 in San Diego.

Did you miss our previous article…

https://constructionosa.org/?p=399

Women in Construction: Planning Your Post-Pandemic Career Path

If you’re a woman working in the post-pandemic world, construction isn’t a bad place to be. While there is still a wage gap between men and women, it’s less than in other industries, with women earning 99.1% of what their male counterparts make.

The pandemic hasn’t slowed things down, either. A survey of 700 women in construction in March found that 58% said they’re working about the same compared with before the pandemic, while nearly one-third (32%) said they’re working more, and only 1 in 10 reported working fewer hours. Meanwhile, 71% said opportunities are on the increase, while 28% said they were about the same, leaving just 1% to report they were declining.

This leaves women in construction with a leg up on women in other fields, such as retail and hospitality, who have been struggling to retain their jobs during the pandemic. Instead of scrambling to get back to where they were pre-COVID, many women in construction are riding the crest of a wave.

Opportunities Abound

Restaurant, retail, and travel industry closures hit women in those industries hard. Employment in February was down by 383,000 jobs compared with the year-earlier total in retail alone. Leisure and hospitality employment job losses were even worse, at 3.9 million.

Although many jobs in the latter sector are opening back up as travel and tourism increase, many displaced workers will see a chance to shift gears and find opportunities await in construction, where a March estimate identified a need for 200,000 skilled craft professionals. And these positions pay well, upwards of $66,000 for a carpenter, for example. To compare, a general contractor can make an average salary of $70,000 to $95,000 a year.

There’s room for growth, too: Women make up just 10.3% of the construction workforce, which means there’s both a challenge and an opportunity.

Stereotypes Persist

Many women may not even consider construction because of stereotypes that have kept trade industries male-dominated for some time. Media representations from Bob the Builder to Wreck it Ralph to Tim Allen’s Home Improvement are geared toward male audiences.

Women, meanwhile, have been dismissed as no longer “needed” in construction jobs.This is similar to what happened after World War II ended, with “homemaker” conventions resurfacing to replace Rosie the Riveter.

It’s still assumed by many that construction is a male industry. But that’s simply a false assumption, and it’s limiting both women and the companies that could be benefiting from their talents.

Challenging those stereotypes will be important moving forward in order to take advantage of opportunities that are opening up. A more diverse workforce increases the labor pool. It also boosts productivity and provides a greater variety of perspectives to promote innovation and better decision-making.

Technologies & Trends Emerge

From drones and artificial intelligence to 3D printing and modeling, construction technology is becoming more relevant by the day. As the industry as a whole embraces data as a driving factor in decision-making, it is becoming more obvious that the soft skills women bring to the table as effective communicators and team players improve both productivity and safety. That means, for women in tech, the emphasis on working smarter could help them get their foot in the proverbial door.

Similarly, emerging trends in construction will expand opportunities for women in tech to break into adjacent industries. For example, new directives designed to address the climate crisis have resulted in an industry-wide push to achieve net-zero energy in both new construction and retrofitting. As a result, subcontractors in heating, plumbing, electrical, and alternative energy (to name a few) will be looking for sustainability experts to help them “go green” and stay relevant.

Entrepreneurship is Rewarded

Self-employed construction workers are a force to be reckoned with. More than 23% of U.S. construction workers were self-employed in 2018, compared to 10% of the broader workforce.

As of 2016, more than one-third of carpenters (33.6%) were self-employed, nearly 42% of floor layers were, along with 38% of construction managers and 41.3% of construction and maintenance painters.

That means there’s plenty of opportunity to be your own boss under the right conditions. Of course, that takes understanding things like the need for various kinds of insurance, such as workers’ compensation (if you have employees), property and liability, and general liability.

It also means having enough capital and credit to make a go of it. If you’re thinking of going into business yourself, now is the time to get your finances in order so you’ll be in a position to invest in yourself and your company. As an added bonus, taking steps to build your credit can save you up to $11,460 per year in interest rates and fees on loans and credit cards.

## Alternatives are Available

If you have taken time off from your career, either due to the pandemic or personal reasons, you have options. Returnships encourage professionals who’ve taken a break from the workforce to get back in the game.

These paid internships allow companies and potential employees to get a feel for each other and provide training that can help in the long run, whether you wind up with that particular company or not. Companies like CDM Smith and Caterpillar are among those that offer or have offered returnships, often with a focus on women.

Opportunities in construction will continue to expand, but as stereotypes persist, it’s important for women to remain confident in what they have to offer, because it’s significant. Women can provide a broader and more diverse pool of labor and ideas that will serve the construction industry well in the years to come.

Schedule a Demo

Jessica Larson is a married Midwestern mom and a solopreneur. She creates online courses for students, and has started and run several other businesses through the years. Her goals are to support her family while still actually spending time with them, to act as an entrepreneurial role model for her two daughters, and to share what she has learned through The Solopreneur Journal.

Did you miss our previous article…

https://constructionosa.org/?p=387